Continuous operation steam explosion unit

A steam explosion machine and steam explosion technology, applied in feed, grain processing, food science, etc., can solve the problems of limited volume of steam explosion chamber and low operation efficiency, and achieve high work efficiency, continuous operation, and convenient and fast steam explosion operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described further according to accompanying drawing:

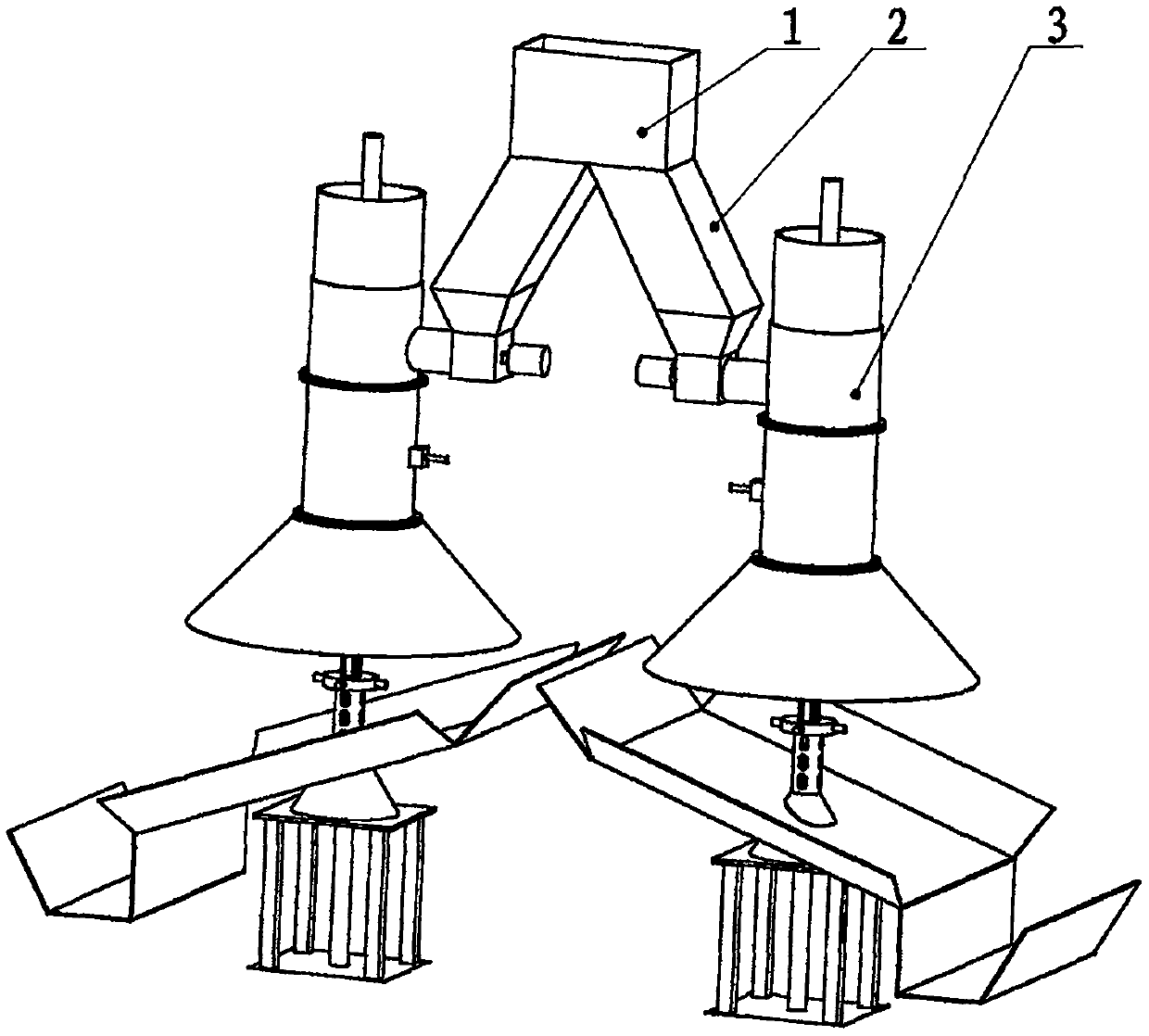

[0022] A continuous operation steam explosion unit is mainly composed of a feed distributor 1, a material delivery pipeline 2 and two or more continuous operation steam explosion machine units 3, and the feed distributor 1 is connected to the continuous operation steam explosion machine through the material delivery pipeline 2 Unit 3 is connected.

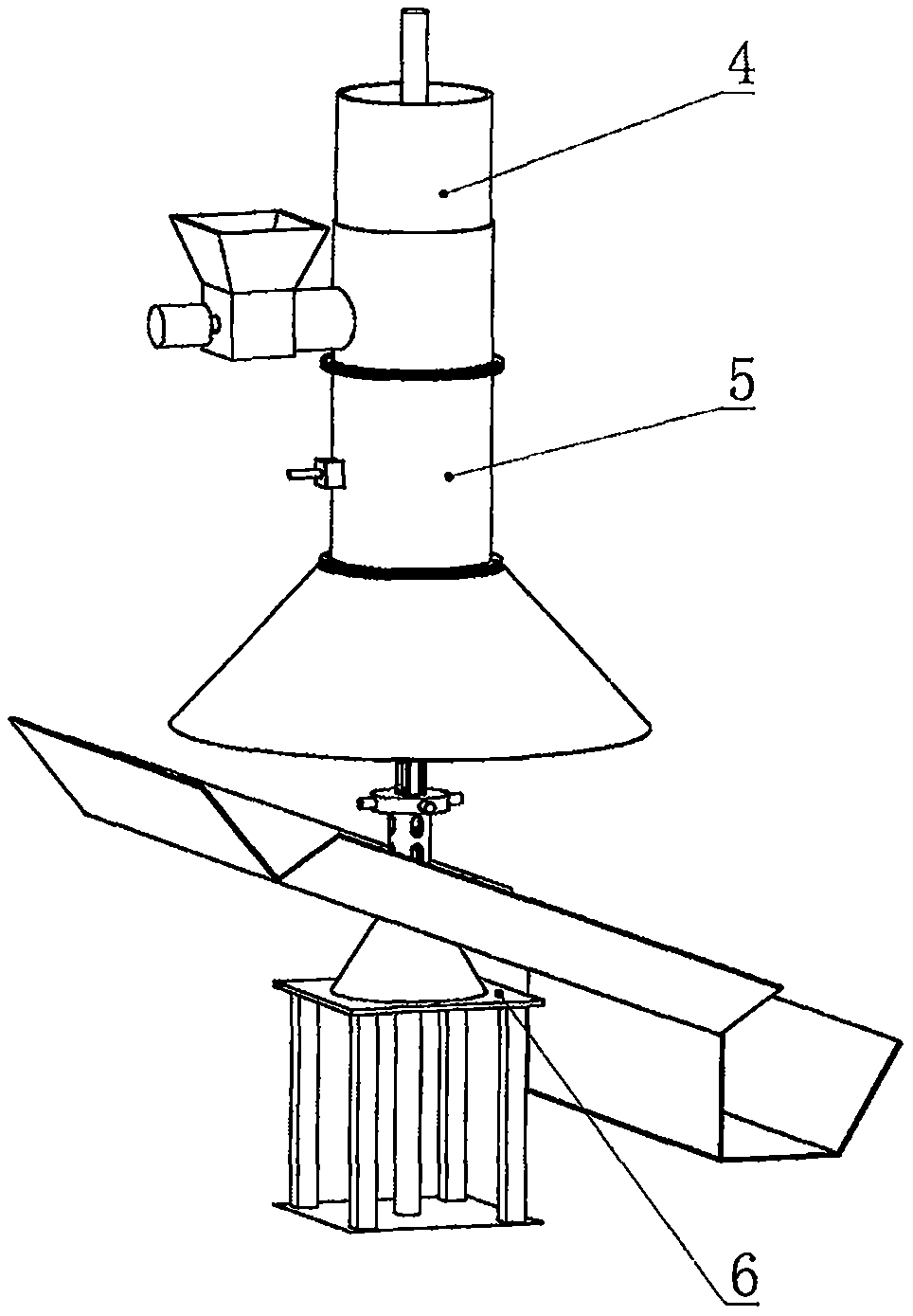

[0023] Continuous operation steam explosion machine unit 3 is mainly composed of feed compression piston 4, feed steam explosion cylinder 5 and support frame 6, wherein feed compression piston 4 is mainly composed of compression piston barrel 23 and feed compression piston oil cylinder 22 , are connected by flanges.

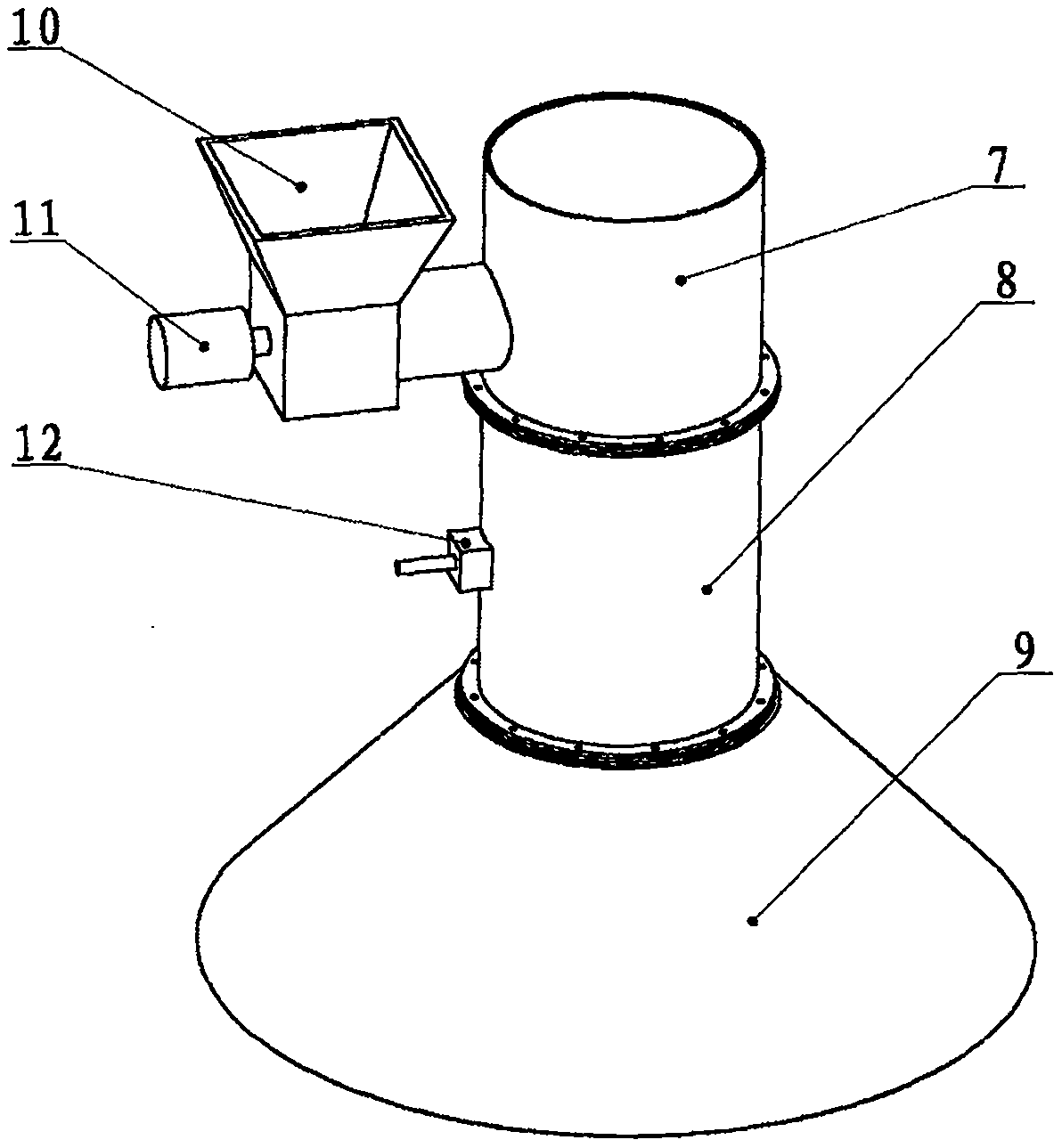

[0024] The feed steam explosion cylinder 5 is mainly composed of a feed cylinder 7, a steam explosion cylinder 8, a material guide muffler cover 9, a steam inlet flange 12, a hopper 10, a forced conveying screw 24 and a motor 11. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com