Single quantum dot scanning near-field optical microprobe and system, detection device and method

A scanning near-field optics, single quantum dot technology, applied in the field of scanning probe imaging, can solve the problems of complex imaging conditions, high excitation power, wide spectrum, etc., achieve good imaging resolution, increase signal-to-noise ratio, and luminescence signal-to-noise better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

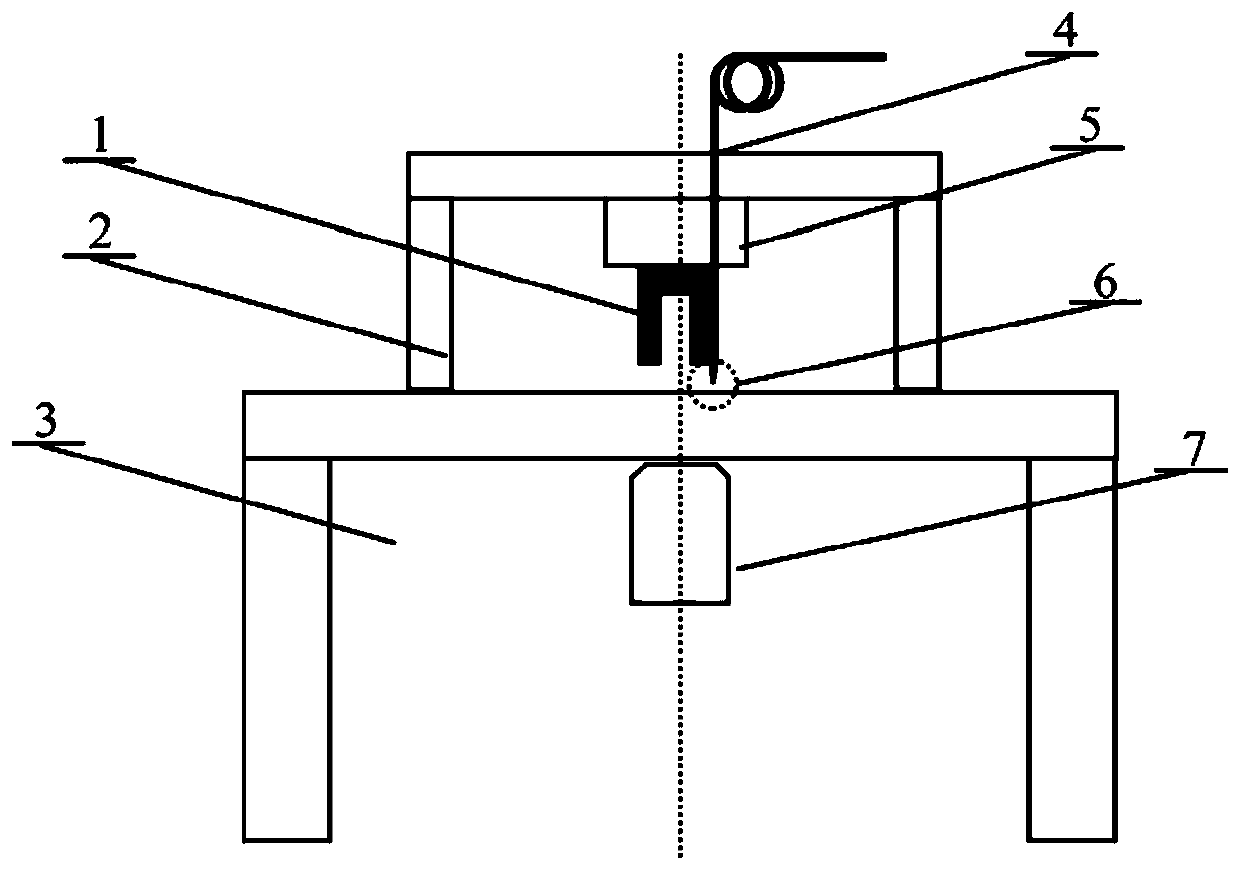

[0025] Such as figure 1 As shown, a SNOM system probe system based on an atomic force microscope (AFM), including a self-drawn tapered optical fiber with a tip diameter of 50-500nm as a scanning probe, a quartz tuning fork with a resonant peak at 40KHz, and a front A signal amplifier, a circuit board, and an AFM-based scanning feedback system. The tapered optical fiber 4 is adhered to the quartz tuning fork 1, and is connected with the pre-signal amplifier 5 through the circuit board, and the output signal of the pre-signal amplifier is connected to the scanning feedback system to form a scanning probe system based on the tapered optical fiber . The optical microscope 3 is placed upside down under the single quantum dot scanning near-field optical microprobe, a glass slide is placed on the objective lens, and the single quantum dot sample and the nano metal particles to be tested are placed on the glass slide. The AFM head 2 is coaxially combined with the inverted optical mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com