Dual-frequency thermal plasma jet generating device

A technology of thermal plasma and plasma, which is applied in the field of plasma jet, can solve the problems of single radio frequency power supply, high processing cost, single adjustment of thermal plasma parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

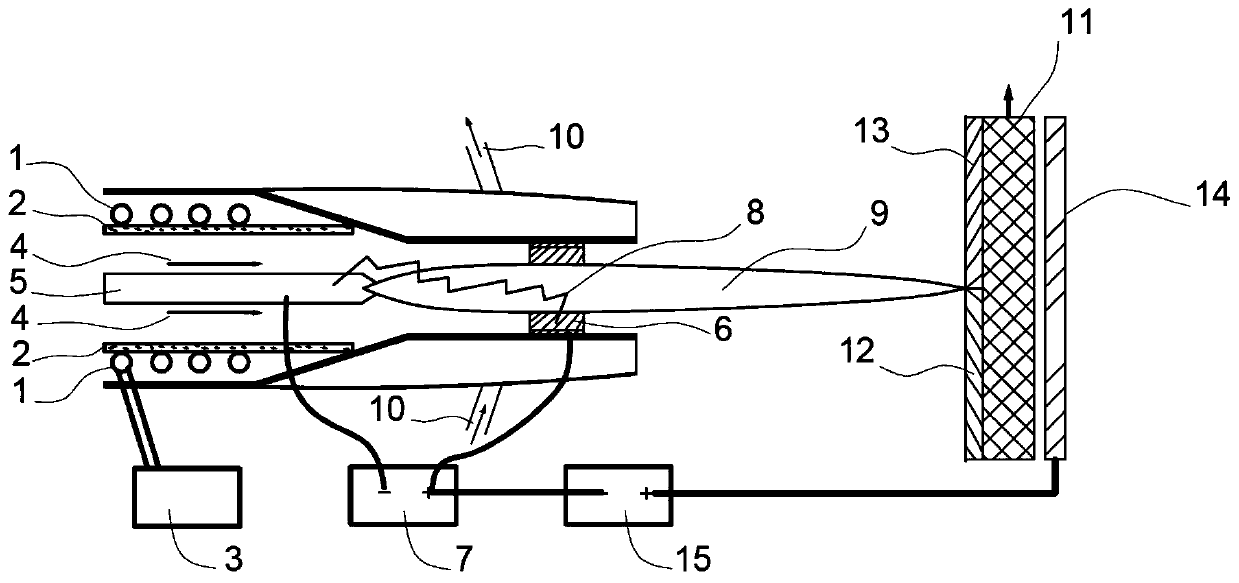

[0021] see figure 1 , which is a schematic structural diagram of a dual-frequency thermal plasma jet generating device, including: a device body, a radio frequency coil 1, a high temperature resistant insulating baffle 2, a radio frequency power supply 3, a jet source cathode 5, a jet source anode 6 and an arc power supply 7 A plasma reaction area is formed in the device body; the radio frequency power supply 3 is electrically connected to the radio frequency coil 1; the radio frequency coil 1 is used to ionize the discharge gas 4 entering the plasma reaction area to generate pre-ionization Plasma; the high temperature resistant insulating baffle 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com