Preparation method of iron-manganese bimetal composite catalyst and application thereof in the purification of industrial waste water

A composite catalyst, industrial wastewater technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as incomplete removal of organic matter, and achieve strong catalytic ozone. The ability to decompose to generate OH, low energy consumption, and the effect of improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method for an iron-manganese bimetallic composite catalyst, comprising the following steps:

[0036] (1) Soak activated carbon with a particle size of 2 mm in nitric acid solution with a volume concentration of 8% for 4 hours, take out the modified activated carbon, and wash it repeatedly with distilled water until the pH does not change, then place it in an oven to dry to obtain the modification Activated carbon;

[0037] (2) Fe(NO 3 ) 3 9H 2 O was added to 45% Mn(NO 3 ) 2 A mixed solution is made in the solution, so that Fe(NO 3 ) 3 9H 2 O: Mn(NO 3 ) 2 The molar ratio is 1:1.8, the modified activated carbon is added to the mixed solution, and the temperature is 30 °C in a water bath for 8 hours to complete the modification of the modified activated carbon on Fe(NO 3 ) 3 , Mn(NO 3 ) 2 adsorption;

[0038] (3) will adsorb Fe(NO 3 ) 3 , Mn(NO 3 ) 2 The modified activated carbon was taken out from the solution, after cleaning and drying, it...

Embodiment 2

[0042] The operating steps in the present embodiment are the same as in Example 1, the difference is that Fe(NO 3 ) 3 9H 2 O and Mn(NO 3 ) 2 Replaced by adding only Fe(NO 3 ) 3 9H 2 O or just add Mn(NO 3 ) 2 .

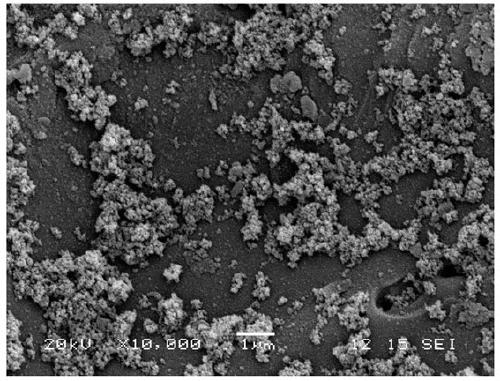

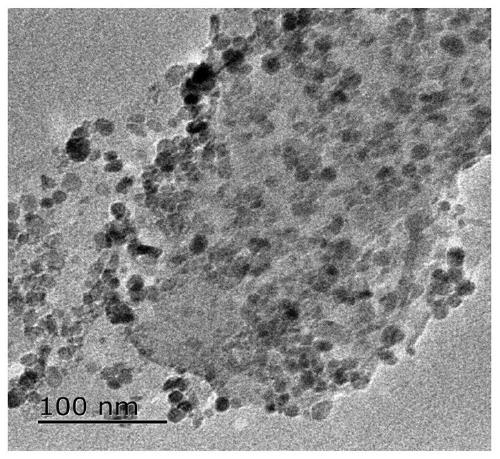

[0043] Will Figure 5 A transmission electron microscope image of a single-component manganese oxide supported on activated carbon, Figure 6 Transmission electron microscope images of single-component iron oxides supported on activated carbon, comparing figure 2 , Figure 5 , Figure 6 , it can be seen that the single-component manganese oxide particles agglomerate very seriously, resulting in insufficient dispersion of active components on the activated carbon; although the single-component iron oxide particles are dispersed relatively widely, its loading capacity is very small and the loading rate is very low . The iron-manganese bimetallic catalyst has a large particle dispersion and a high loading rate. Fe(NO 3 ) 3 9H 2 O and Mn(NO 3 ) 2 It is...

Embodiment 3

[0045] A preparation method for an iron-manganese bimetallic composite catalyst, comprising the following steps:

[0046] (1) Soak the activated carbon with a particle size of 5 mm in a nitric acid solution with a volume concentration of 10% for 6 hours, take out the modified activated carbon and wash it repeatedly with distilled water until the pH does not change, then place it in an oven to dry to obtain the modification Activated carbon;

[0047] (2) Fe(NO 3 ) 3 9H 2 O was added to 50% Mn(NO 3 ) 2 A mixed solution is made in the solution, so that Fe(NO 3 ) 3 9H 2 O: Mn(NO 3 ) 2 The molar ratio is 1:2.5, the modified activated carbon is added to the mixed solution, and the temperature is 45 °C in a water bath for 9 hours to complete the modification of Fe(NO 3 ) 3 , Mn(NO 3 ) 2 adsorption;

[0048] (3) will adsorb Fe(NO 3 ) 3 , Mn(NO 3 ) 2 The modified activated carbon was taken out from the solution, after cleaning and drying, it was calcined at 400°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com