Porous material dynamic rotary sintering forming method and forming device

A technology for sintering and forming porous materials, which is applied in the field of dynamic rotary sintering and forming methods for porous materials and its forming devices. Stable size distribution, small size change and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 (Examples 1 to 5 are different in the grades of ultra-high molecular weight polyethylene, which are XM220, M1, M2, M3, and GUR4120, respectively. UHMWPEs of different grades have different microscopic morphologies).

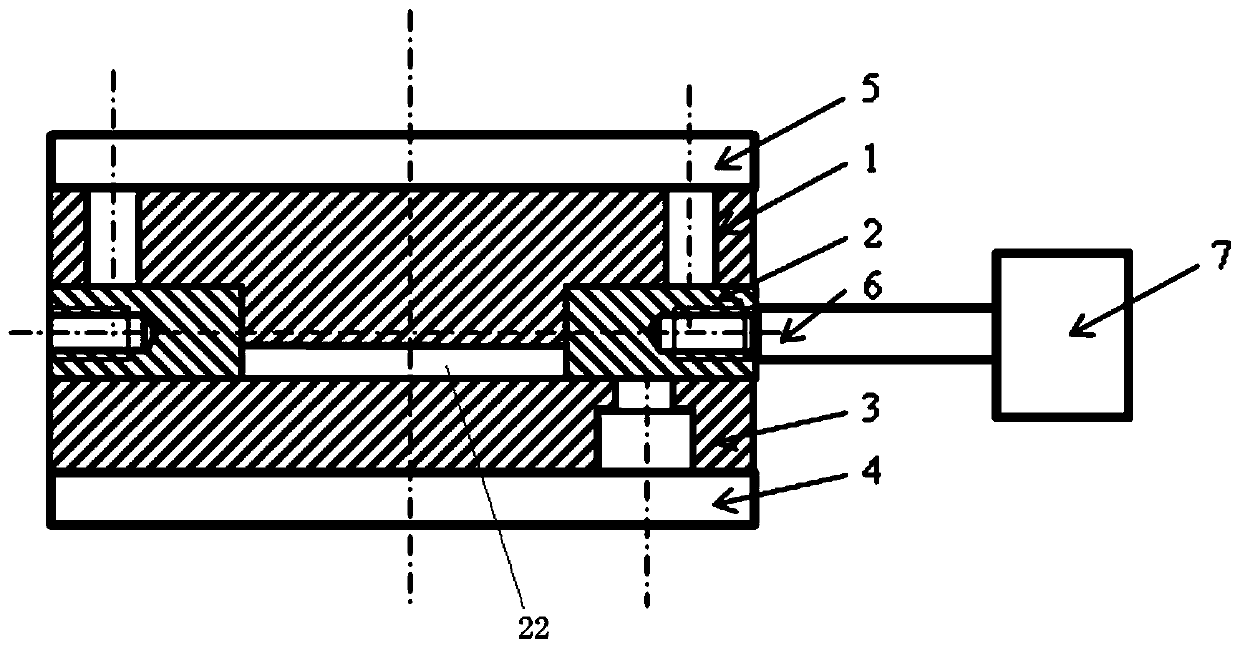

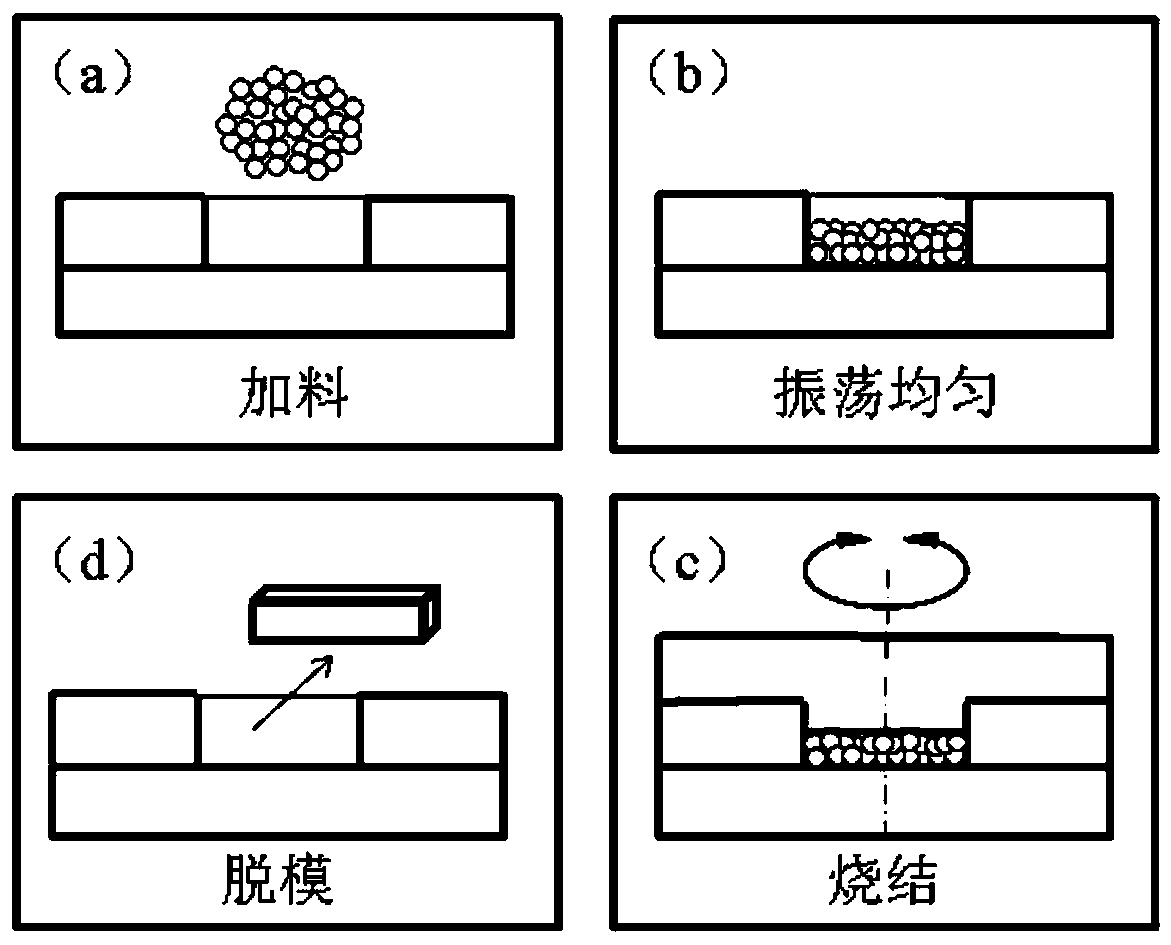

[0044] (1) Cleaning the sintering molding device: clean the cavity of the sintering molding device, and spray a layer of release agent on the material sintering chamber 22.

[0045] (2) Feeding: Weigh the set amount of UHMWPE (brand XM220) powder with an electronic scale, and then put the powder into the cavity of the sintering molding device. After the filling is completed, the sintering molding device is shaken to ensure the material as much as possible The filling is even.

[0046] (3) Fix the sintering molding device: close the female mold and the male mold, and connect and fix them with bolts (not shown in the figure).

[0047] (4) Temperature control: adjust the temperature controller (existing technology, not shown in the figure) to set the requir...

Embodiment 2

[0052] (1) Cleaning the sintering molding device: clean the cavity of the sintering molding device, and spray a layer of release agent.

[0053] (2) Feeding: Weigh the set amount of UHMWPE (brand name M1) powder with an electronic scale, and then put the powder into the cavity of the sintering molding device. After the filling is completed, the sintering molding device is shaken to ensure the material as much as possible The filling is even.

[0054] (3) Fixing the sintering molding device: close the female mold and the male mold, and fix them with bolts.

[0055] (4) Temperature control: adjust the temperature controller to set the required sintering temperature in the temperature range of 170~210℃, completely cover the filled sintering molding device with an electric heating mantle, and install a thermocouple , Monitoring temperature changes at any time.

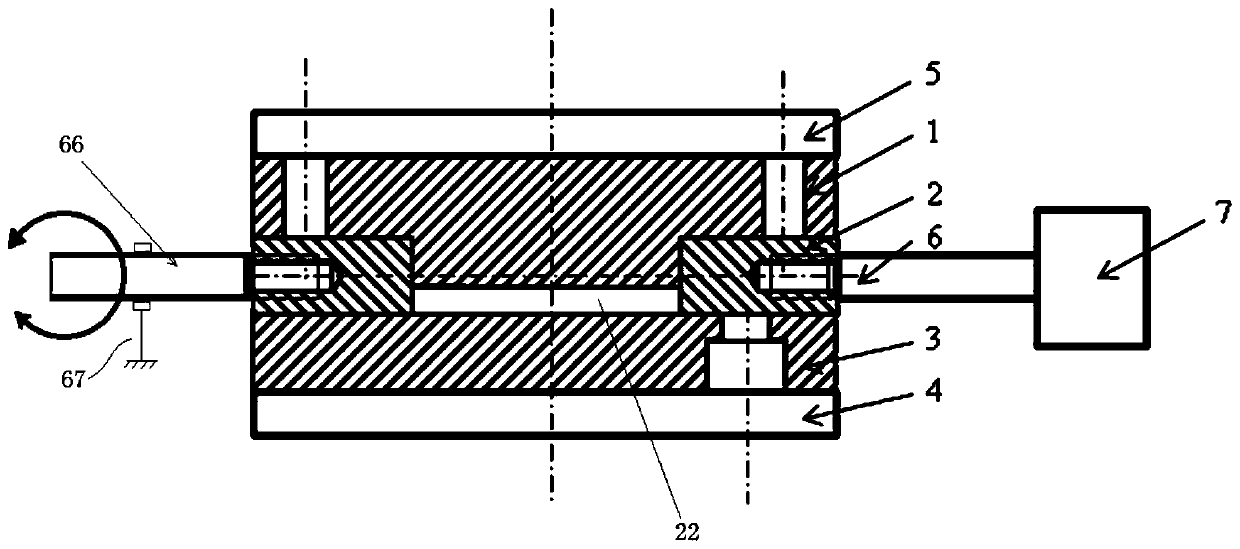

[0056] (5) Sintering: Fix the sintering molding device on the rotating mechanism, start the rotating mechanism, the DC motor st...

Embodiment 3

[0060] (1) Cleaning the sintering molding device: clean the cavity of the sintering molding device, and spray a layer of release agent.

[0061] (2) Feeding: Weigh the set amount of UHMWPE (brand M2) powder with an electronic scale, and then put the powder into the cavity of the sintering molding device. After the filling is completed, oscillate the sintering molding device to ensure the material as much as possible The filling is even.

[0062] (3) Fixing the sintering molding device: close the female mold and the male mold, and fix them with bolts.

[0063] (4) Temperature control: adjust the temperature controller to set the required sintering temperature in the temperature range of 170~210℃, completely cover the filled sintering molding device with an electric heating mantle, and install a thermocouple , Monitoring temperature changes at any time.

[0064] (5) Sintering: Fix the sintering molding device on the rotating mechanism, start the rotating mechanism, the DC motor starts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com