Humidity-regulating phosphogypsum wall material suitable for fabricated building and preparation method of humidity-regulating phosphogypsum wall material

A technology of wall material and phosphogypsum, which is applied in the field of moisture-regulating functional phosphogypsum wall material and its preparation, can solve the problems of less reports on functional prefabricated component materials, improve comprehensive utilization rate, reduce material bulk density, The effect of reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

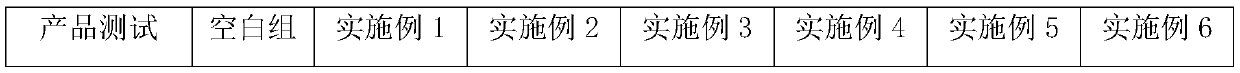

Examples

Embodiment 1

[0032] A phosphogypsum wall material with humidity control function suitable for prefabricated buildings, the preparation method of which comprises the following steps:

[0033] 1) Take each raw material component according to the following proportioning ratio:

[0034] 100 parts by weight of phosphorus building gypsum, vitrified microbeads are added according to 10% of the volume of phosphorus building gypsum, 0.3 parts by weight of polycarboxylic acid series HC water reducer, 0.15 parts by weight of air-entraining agent K12, and 5 parts by weight of modified composite diatomite , 0.05 parts by weight of SC gypsum retarder;

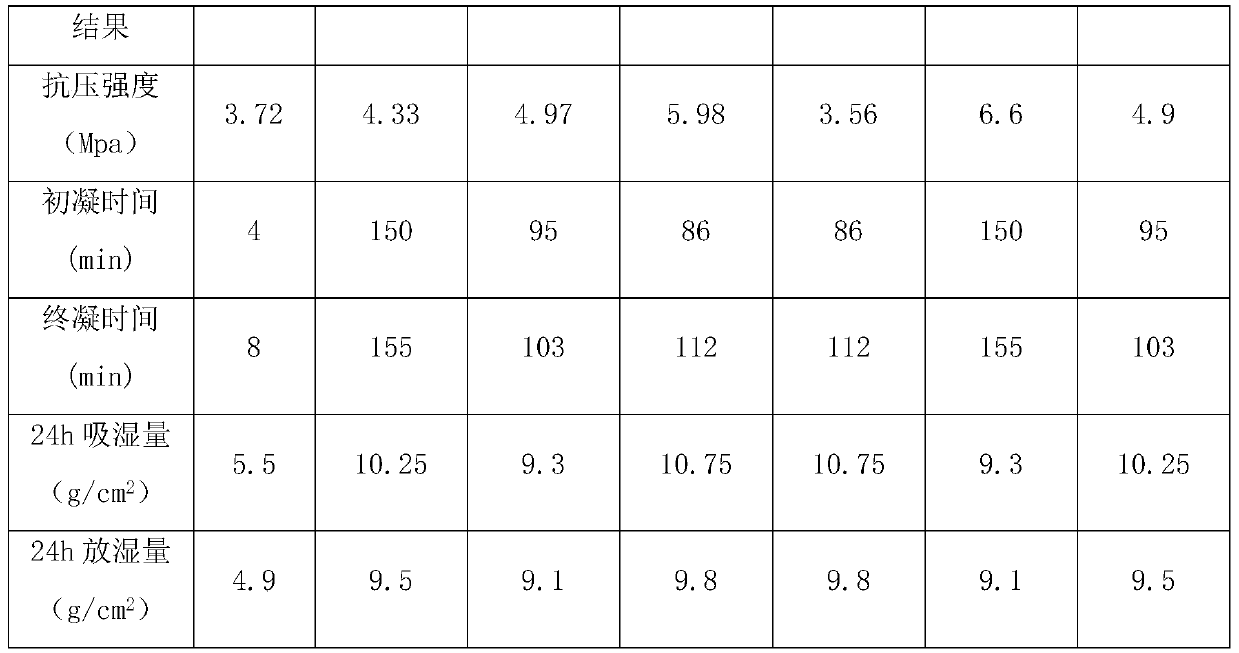

[0035] The preparation method of the modified composite diatomite used is as follows: pre-calcining the diatomite at 750°C for 1 hour to remove moisture, grinding it into diatomite powder for later use, and then mixing 20wt% hydrogen with stirring in an ice-water bath. Add sodium oxide solution dropwise into acrylic acid for neutralization. When the neutr...

Embodiment 2

[0038] A phosphogypsum wall material with humidity control function suitable for prefabricated buildings, the preparation method of which comprises the following steps:

[0039] 1) Take each raw material component according to the following proportioning ratio:

[0040] Phosphorus building gypsum 100 parts by weight, vitrified microbeads added volume is 15% of the volume of phosphorus building gypsum, 0.4 parts by weight of melamine water reducer SM, 0.1 parts by weight of air-entraining agent K12, 10 parts by weight of modified composite diatomite, SC 0.1 parts by weight of gypsum retarder;

[0041] The preparation method of the modified composite diatomite used is as follows: pre-calcining the diatomite at 750°C for 1 hour to remove moisture, grinding it into diatomite powder for later use, and then mixing 20wt% hydrogen with stirring in an ice-water bath. Add sodium oxide solution dropwise into acrylic acid for neutralization. When the neutralization degree reaches 75%, ad...

Embodiment 3

[0044] A phosphogypsum wall material with humidity control function suitable for prefabricated buildings, the preparation method of which comprises the following steps:

[0045] 1) Take each raw material component according to the following proportioning ratio:

[0046] 100 parts by weight of phosphorus building gypsum, the added volume of vitrified microbeads is 20% of the volume of phosphorus building gypsum, 0.5 parts by weight of FDN naphthalene-based water reducer, 0.05 parts by weight of air-entraining agent K12, 15 parts by weight of modified composite diatomite, 0.15 parts by weight of SC gypsum retarder;

[0047] The preparation method of the modified composite diatomite used is as follows: pre-calcining the diatomite at 750°C for 1 hour to remove moisture, grinding it into diatomite powder for later use, and then mixing 20wt% hydrogen with stirring in an ice-water bath. Add sodium oxide solution dropwise into acrylic acid for neutralization. When the neutralization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com