Enzymolysis-membrane filtration circulating device and method for preparing shellfish polypeptides by same

A circulatory device and membrane filtration technology, which can be used in peptide preparation methods, sterilization methods, biochemical equipment and methods, etc., can solve the problems of excessive degradation of substrates, lack of continuity in operation, and low utilization of enzymes. Achieve the effect of improving the conversion rate, improving the utilization rate of raw materials, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

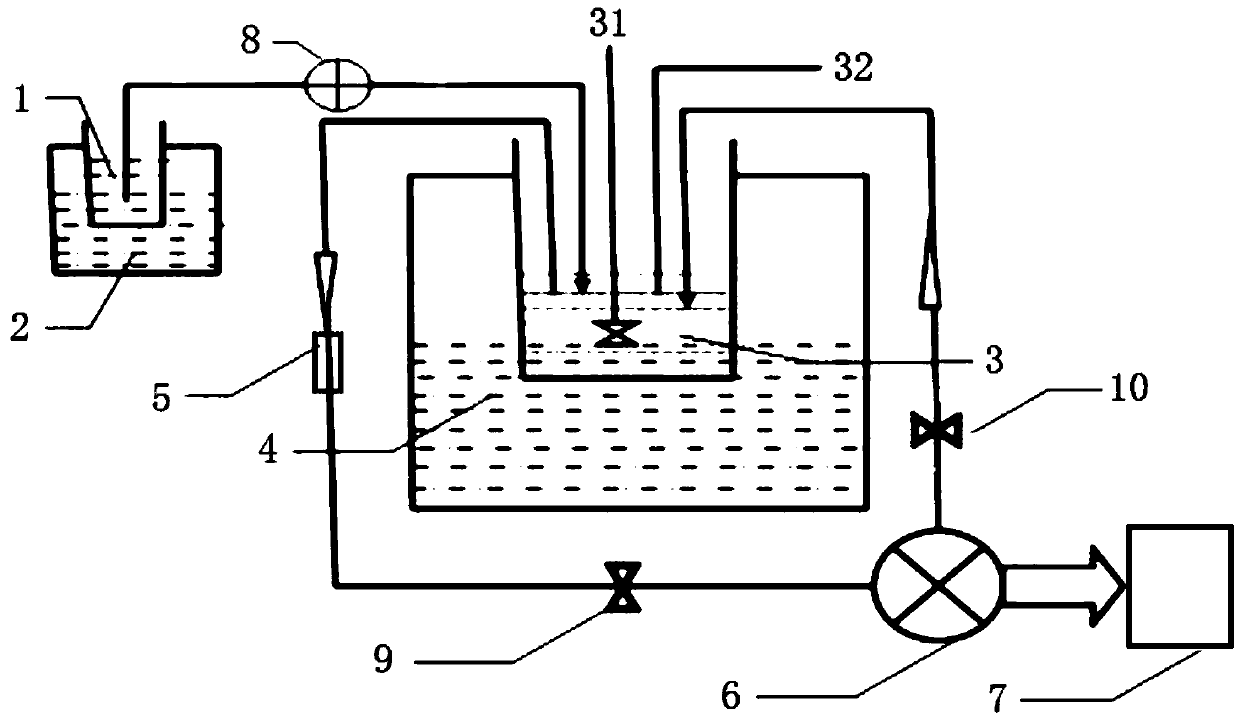

[0024] Embodiment 1: a kind of enzymolysis-membrane filtration circulation device, as figure 1 As shown, it includes a raw material pool 1, a first constant temperature tank 2, an enzymatic hydrolysis tank 3, a second constant temperature tank 4, a centrifugal device 5, a membrane filtration module 6, a liquid collection tank 7, a feed pump 8, a first circulation pump 9 and The second circulating pump 10; the raw material pool 1 is arranged in the inside of the first constant temperature tank 2, and the raw material pool 1 is connected with the enzymolysis pool 3 through the feeding pump 8; the enzymolysis pool 3 is arranged in the inside of the second constant temperature tank 4, and the enzymolysis A stirring bar 31 and a pH meter 32 are arranged in the pool 3, and the enzymolysis pool 3 is connected with the inlet of the membrane filter assembly 6 via the centrifugal device 5 and the first circulating pump 9 in sequence; the outlet of the membrane filter assembly 6 is respec...

Embodiment 2

[0025] Embodiment 2: The method for preparing shellfish polypeptides using the enzymolysis-membrane filtration circulation device of Embodiment 1 comprises the following steps:

[0026] (1) Raw material pretreatment: Grind the shellfish meat into minced meat, add 3 times the weight of the minced meat to homogenate with water to obtain a substrate solution with minced shellfish as the substrate, and put it in the raw material of the enzymatic hydrolysis-membrane filtration circulation device In the pool, and the temperature of the first constant temperature tank is controlled at a constant temperature of 40°C;

[0027] (2) Mixed enzyme hydrolysis: control the temperature of the second constant temperature tank at a constant temperature of 40 ℃, pressurize the feed pump, transfer the substrate solution in the raw material pool to the enzymatic hydrolysis pool, and then adjust the pH of the substrate solution value to 7.5, add the mixed enzyme of substrate solution quality 2% in ...

Embodiment 3

[0035] Embodiment 3: The method for preparing shellfish polypeptides using the enzymolysis-membrane filtration circulation device of Embodiment 1 comprises the following steps:

[0036] (1) Raw material pretreatment: Grind the shellfish meat into minced meat, and add 4 times the weight of the minced meat to homogenate to obtain a substrate solution with the minced shellfish as the substrate, which is placed in the raw material of the enzymatic hydrolysis-membrane filtration circulation device In the pool, and the temperature of the first constant temperature bath is controlled at a constant temperature of 50°C;

[0037] (2) Mixed enzyme hydrolysis: control the temperature of the second constant temperature tank at a constant temperature of 50 ℃, pressurize the feed pump, transfer the substrate solution in the raw material pool to the enzymatic hydrolysis pool, and then adjust the pH of the substrate solution When the value reaches 8, add a mixed enzyme with 3% of the mass of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com