Integral superheater

A technology of superheater and main body, which is applied in the field of integrated superheater to achieve efficient recovery and solve the effect of environmental heat pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

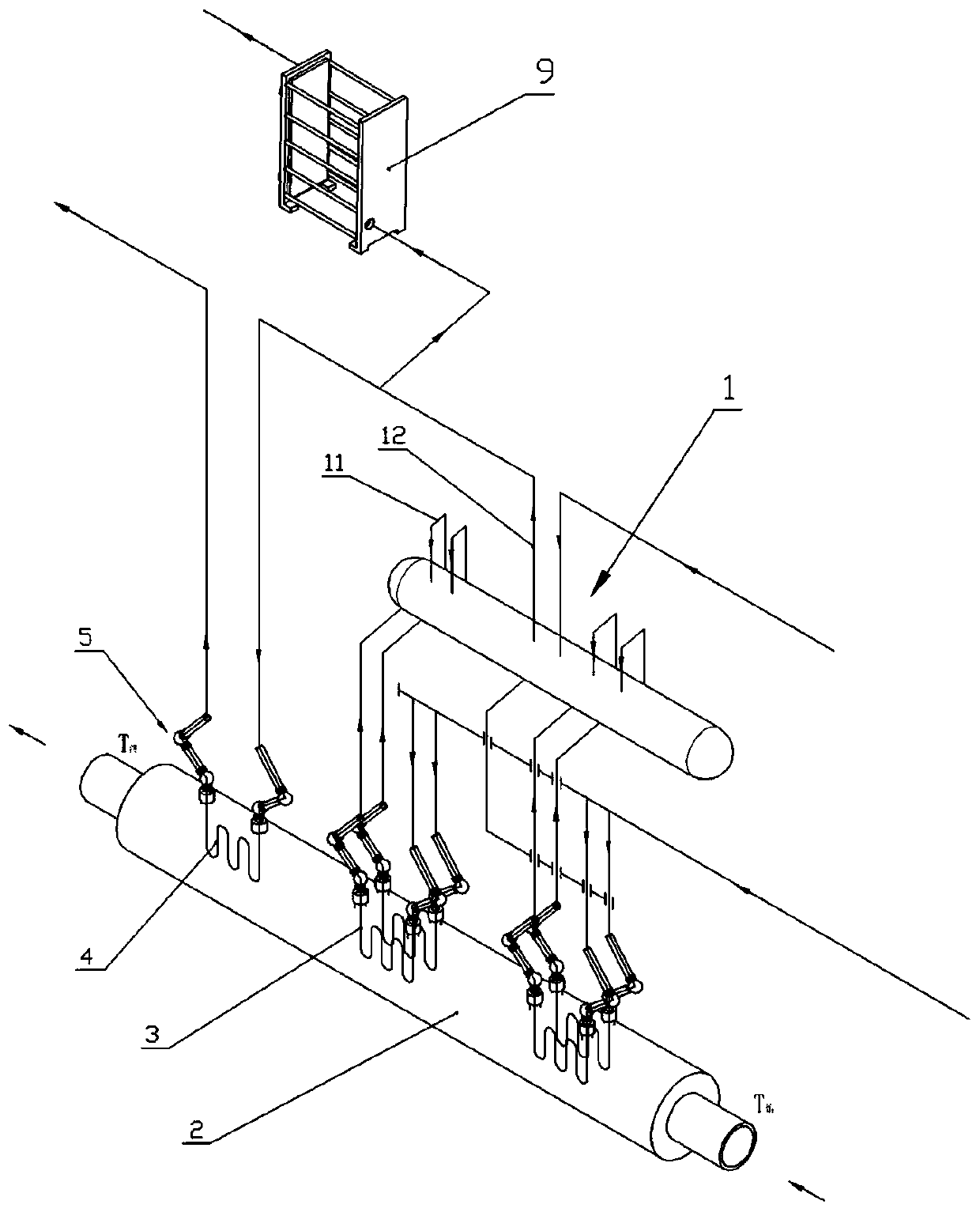

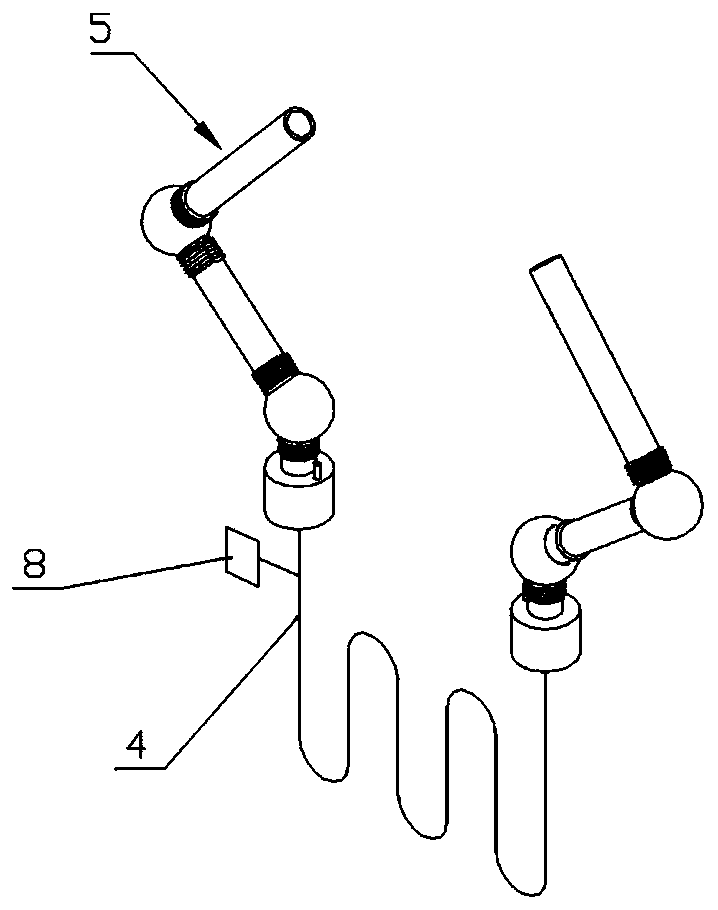

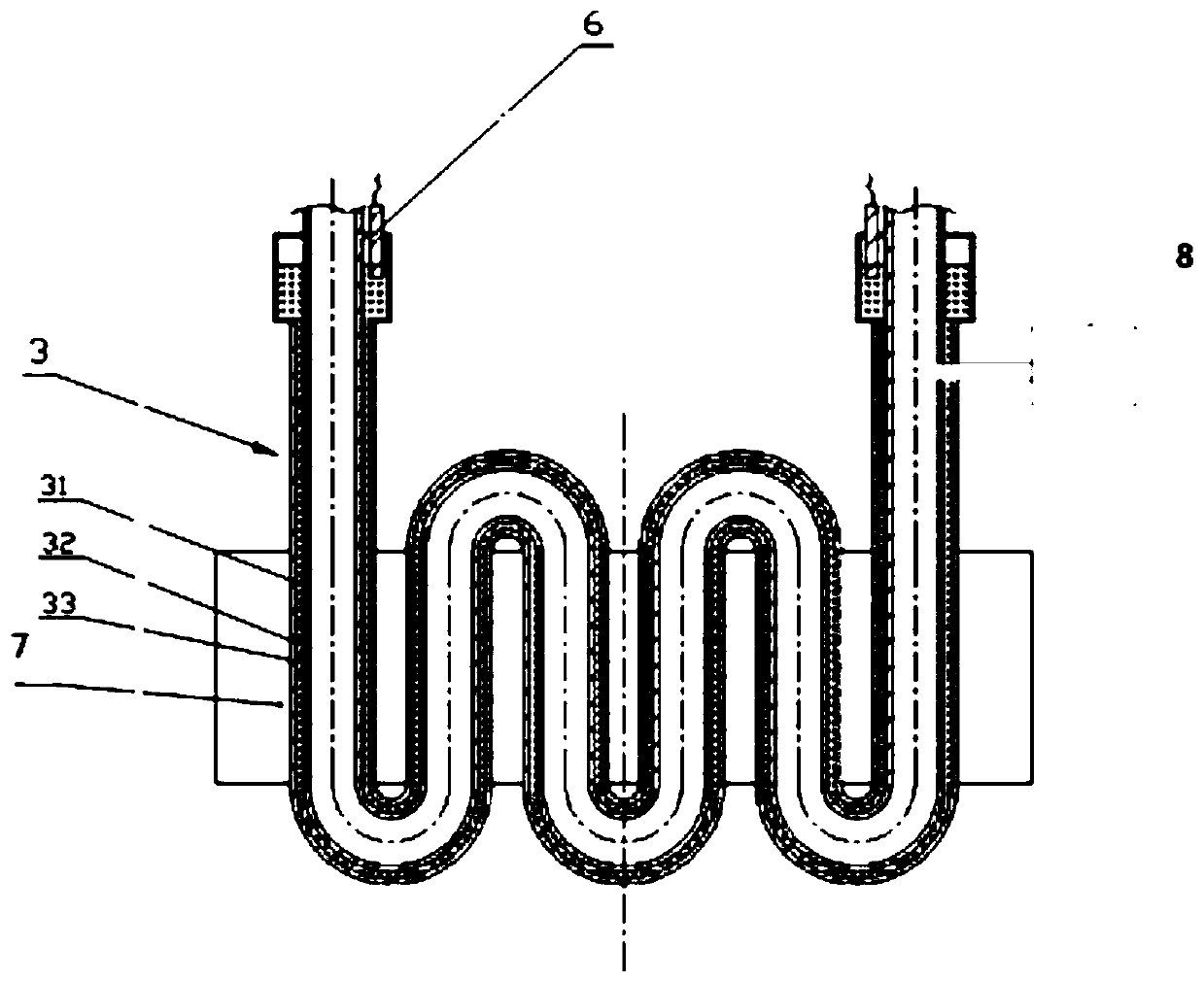

Method used

Image

Examples

Embodiment 2

[0045] Preferred embodiment 2, the difference between this embodiment and preferred embodiment 1 is that the rotary lifting device adopts other schemes, such as Image 6 As shown, the rotary lifting device IIA5 in this embodiment includes a spherical shell A51, a central roller shaft A52 and a bellows A53; the spherical shell is made of metal, and a pair of openings are arranged on it, and an insulating layer A54 is covered on the outside; the central roll The shaft is set in the center of the casing, and the outer surface of the center roller shaft and the inside of the casing are provided with smooth coating A55; the bellows extend between the center roller shaft and the casing, and the two ends extend out of a pair of openings respectively, and the bellows can wrap around the center roller The shafts rotate relative to each other.

Embodiment 3

[0046] Preferred embodiment 3, the difference between this embodiment and preferred embodiment 1 is that the rotary lifting device adopts other schemes, such as Figure 7 As shown, the rotary lifting device IIIB5 includes a central axis tube B51, a sliding telescopic assembly B52, and an insulating elastic shell B53; the central axis tube is cylindrical, with a pair of openings on it, and a graphite smooth coating B54 on its outer surface; The sliding telescopic assembly B52 includes a straight line section B521, a telescopic section B522 and a covering section B523 which are connected in sequence. The covering section is wrapped around the central axis tube and can rotate around the central axis tube; the area outside the central axis tube corresponding to the area between the two telescopic tubes is provided with an insulating elastic shell, and the insulating elastic shell includes insulating shells B531 at both ends and two Elastic shell B532 between insulating segments. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap