Method for detecting purity of 2-chloropropionyl chloride

A technology for the purity and detection method of chloropropionyl chloride, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as unstable results, damage to testing instruments, and research on undetected methods, so as to avoid unstable measurement results and avoid corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

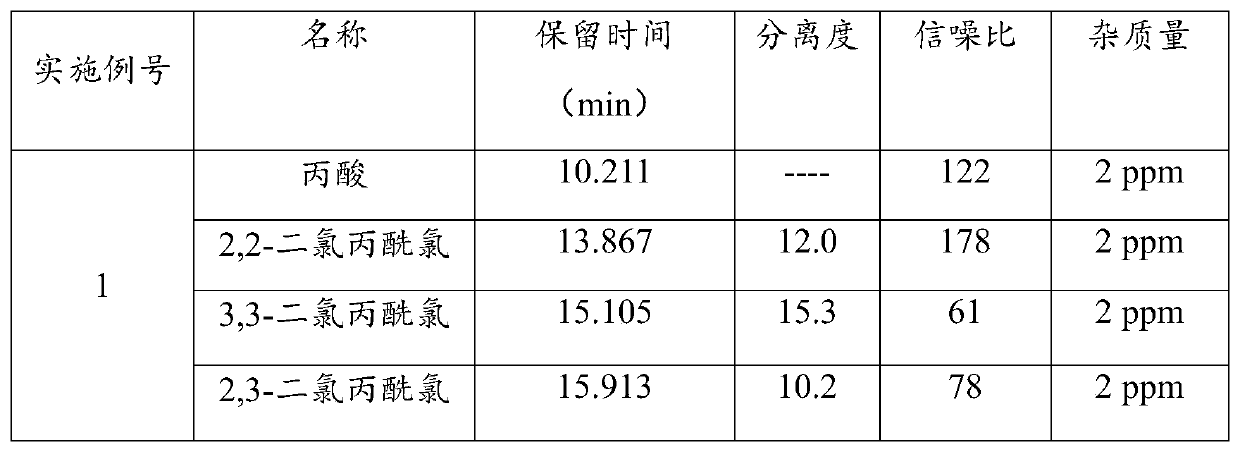

Embodiment 1

[0030] (1) Chromatographic conditions

[0031] Gas chromatograph: Agilent 7890B gas chromatograph;

[0032] Gas chromatography column: dimethylpolysiloxane (30m*0.53mm, 3μm);

[0033] Injection volume: 1μl;

[0034] Detector temperature: 250°C;

[0035] Front inlet temperature: 250°C;

[0036] Detector: FID;

[0037] Split ratio: 10:1;

[0038] Flow rate: 3ml / min;

[0039] Heating program: the initial temperature is 40°C, keep for 6min, then rise to 250°C at 15°C / min, and keep for 5min.

[0040] (2) Sample preparation

[0041] Sample solution preparation: Slowly add 1g of chloropropionyl chloride dropwise to a 10ml volumetric flask containing 8ml of ethanol, wait to cool to room temperature, add ethanol to the mark, and shake well to obtain.

[0042] (3) Detection method

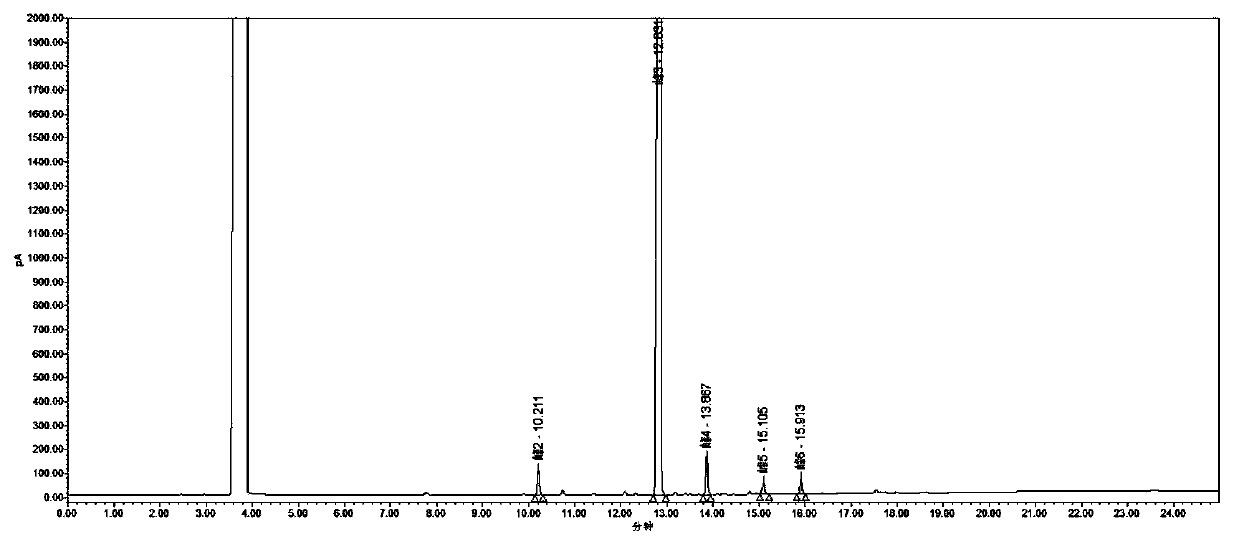

[0043] The autosampler extracts 1ul and injects it into the gas chromatograph, the chromatogram is as follows figure 1 shown.

[0044] (4) calculation

[0045] Calculated by area normalization me...

Embodiment 2

[0058] (1) Chromatographic conditions

[0059] Gas chromatograph: Agilent 7890B gas chromatograph;

[0060] Gas chromatography column: dimethylpolysiloxane (30m*0.53mm, 3μm);

[0061] Injection volume: 1μl;

[0062] Detector temperature: 250°C;

[0063] Front inlet temperature: 250°C;

[0064] Detector: FID;

[0065] Split ratio: 10:1;

[0066] Flow rate: 3ml / min;

[0067] Heating program: the initial temperature is 80°C, keep for 6min, then rise to 250°C at 10°C / min, and keep for 5min.

[0068] (2) Sample preparation

[0069] Sample solution preparation: Slowly add 1g of chloropropionyl chloride dropwise to a 10ml volumetric flask containing 8ml of ethanol, wait to cool to room temperature, add ethanol to the mark, and shake well to obtain.

[0070] (3) Detection method

[0071] The autosampler draws 1ul and injects it into the gas chromatograph.

[0072] (4) calculation

[0073] Calculated by area normalization method.

[0074] (5) Experimental results

[0075] ...

Embodiment 3

[0081] (1) Chromatographic conditions

[0082] Gas chromatograph: Agilent 7890B gas chromatograph;

[0083] Gas chromatography column: dimethylpolysiloxane (30m*0.53mm, 3μm);

[0084] Injection volume: 1μl;

[0085] Detector temperature: 250°C;

[0086] Front inlet temperature: 250°C;

[0087] Detector: FID;

[0088] Split ratio: 20:1;

[0089] Flow rate: 3ml / min;

[0090] Heating program: the initial temperature is 40°C, keep for 6min, then rise to 250°C at 15°C / min, and keep for 5min.

[0091] (2) Sample preparation

[0092] Sample solution preparation: Slowly add 1g of chloropropionyl chloride dropwise to a 10ml volumetric flask containing 8ml of ethanol, wait to cool to room temperature, add ethanol to the mark, and shake well to obtain.

[0093] (3) Detection method

[0094] The autosampler draws 1ul and injects it into the gas chromatograph.

[0095] (4) calculation

[0096] Calculated by area normalization method.

[0097] (5) Experimental results

[0098] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com