Hygroscopic granular cotton and filling cotton containing the granular cotton

A hygroscopic, granular cotton technology, used in protective clothing, fiber treatment, textiles and papermaking, etc., can solve the problems of hygroscopic fiber bulkiness and low resilience, and achieve excellent hygroscopic performance, not easy to be stuffy, and keep fluffy. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

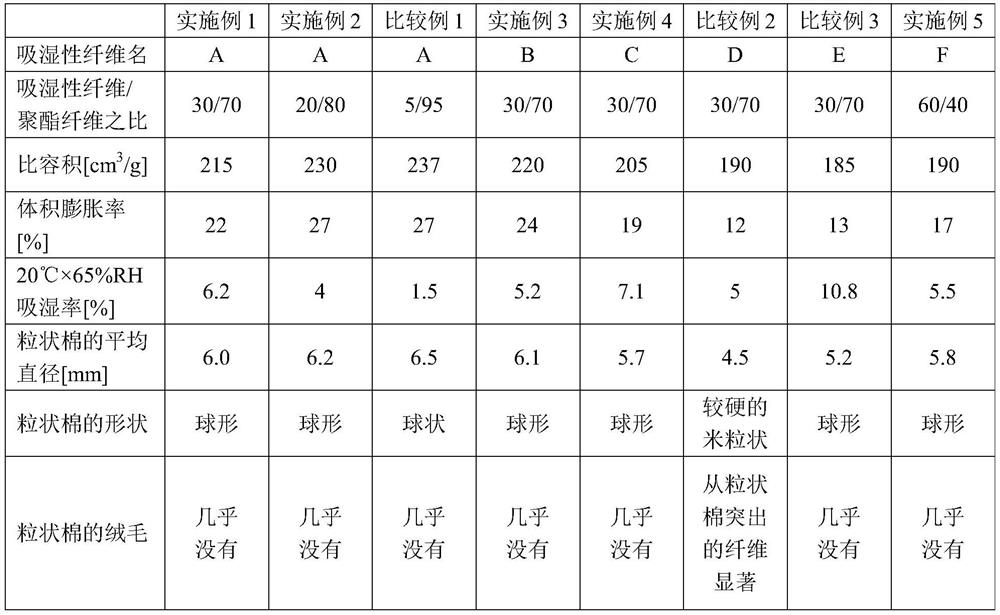

[0047] In order to make this invention understandable, although an Example is shown below, these are mere illustrations, and the gist of this invention is not limited to them. It should be noted that, unless otherwise specified, the parts and percentages in the examples are expressed on a mass basis. In addition, the evaluation method of the characteristic in an Example is as follows.

[0048]

[0049] Measured in accordance with "8.4 fiber length", "8.5 denier", "8.11 initial stretch resistance", and "8.12 crimp" of JIS L 1015:2010.

[0050]

[0051] 1. Proportion of the cross-sectional area of the surface layer in the fiber cross-section

[0052] The sample fiber is immersed in a dyeing bath containing 2.5% cationic dye (Nichilon Black G 200) and 2% acetic acid relative to the mass of the fiber at a bath ratio of 1:80, boiled for 30 minutes, and then washed with water , dehydration, drying. The obtained dyed fiber was sliced perpendicular to the fiber axis, and th...

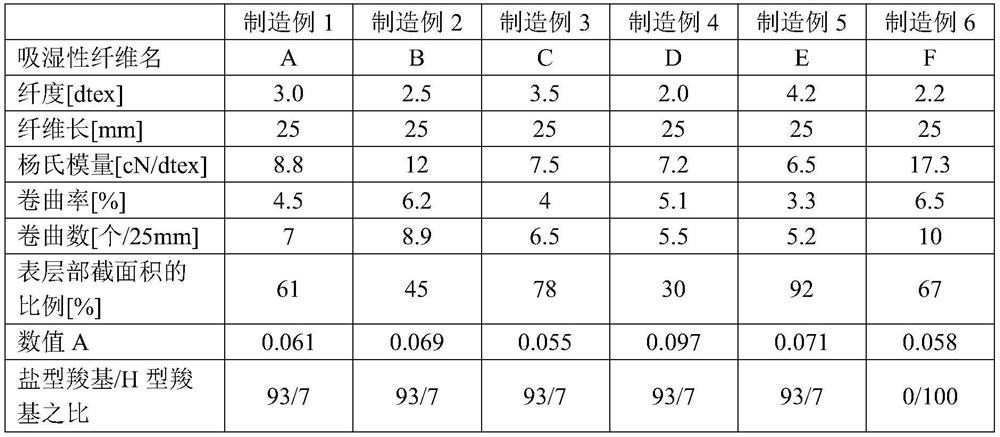

manufacture example 1

[0076] An acrylonitrile-based polymer (intrinsic viscosity [η]=1.5 in dimethylformamide at 30° C.) of 90% by mass of acrylonitrile and 10% by mass of methyl acrylate was dissolved in a 48% by mass aqueous solution of sodium thiocyanate, Thus a spinning dope is prepared. This spinning dope was spun, washed with water, stretched, crimped, and heat-treated according to the usual methods to obtain an acrylic fiber with a single fiber fineness of 1.7 dtex.

[0077] The obtained acrylic fiber was simultaneously subjected to crosslinking introduction treatment and hydrolysis treatment at 100°C for 2 hours in an aqueous solution containing 0.5% by mass of hydrazine hydrate and 2.0% by mass of sodium hydroxide, and treated with an aqueous solution of 8% by mass of nitric acid at 100°C for 3 hours. hours and wash with water. Hygroscopic fiber A was obtained by immersing the obtained fiber in water, adding sodium hydroxide, adjusting pH to 9, washing with water, and drying. Table 1 sho...

manufacture example 2

[0079] In manufacture example 1, the hygroscopic fiber B was obtained similarly except having made the density|concentration of sodium hydroxide into 1.5 mass %. Table 1 shows details and evaluation results of the obtained hygroscopic fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curvature | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com