Crosshead bearing, crosshead, frame, and crosshead internal combustion engine

A technology of crossheads and crosshead pins, which is applied to bearings, connecting rod bearings, bearing components, etc., can solve the problem of oil film damage and achieve the effect of inhibiting damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

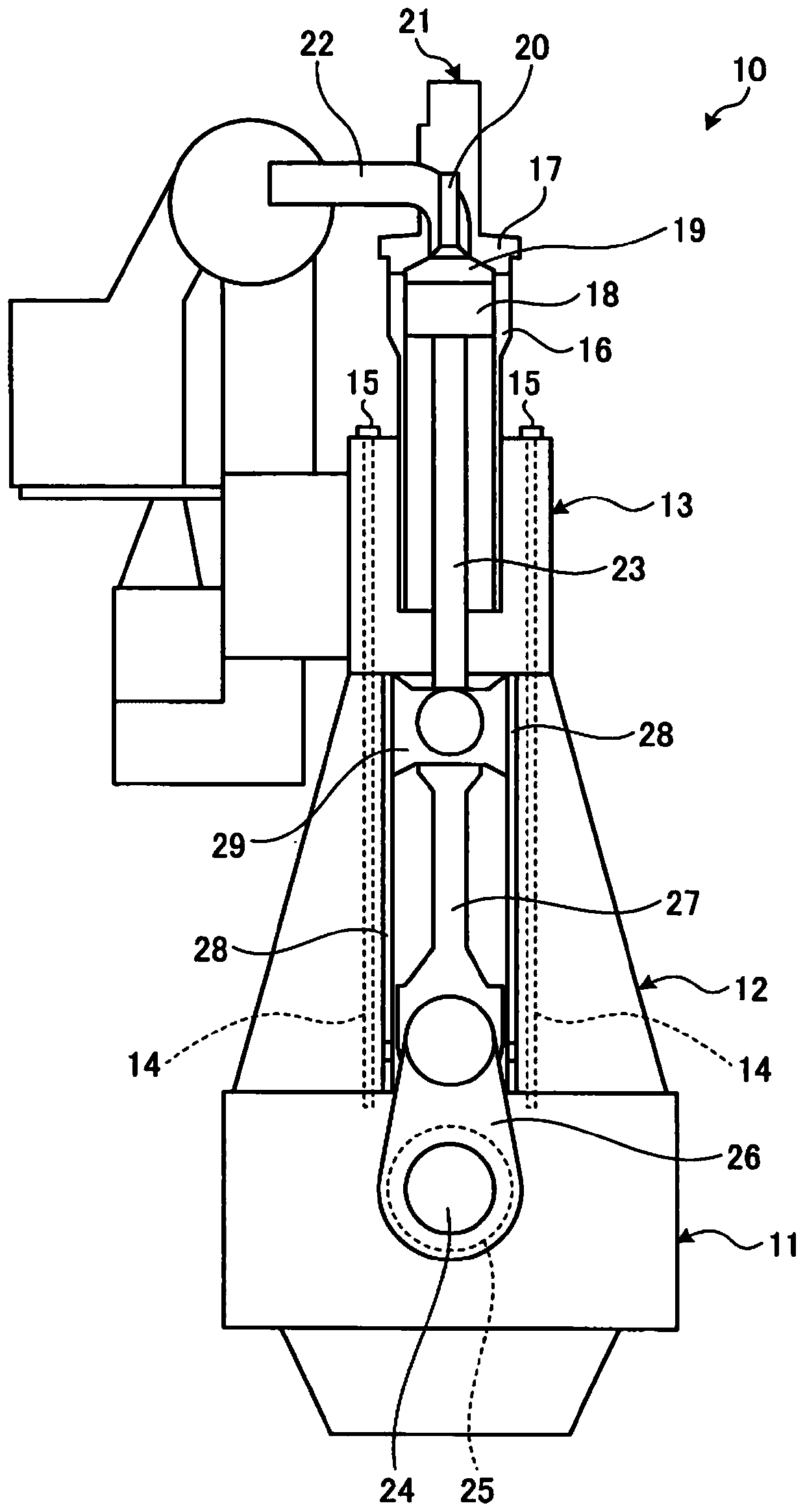

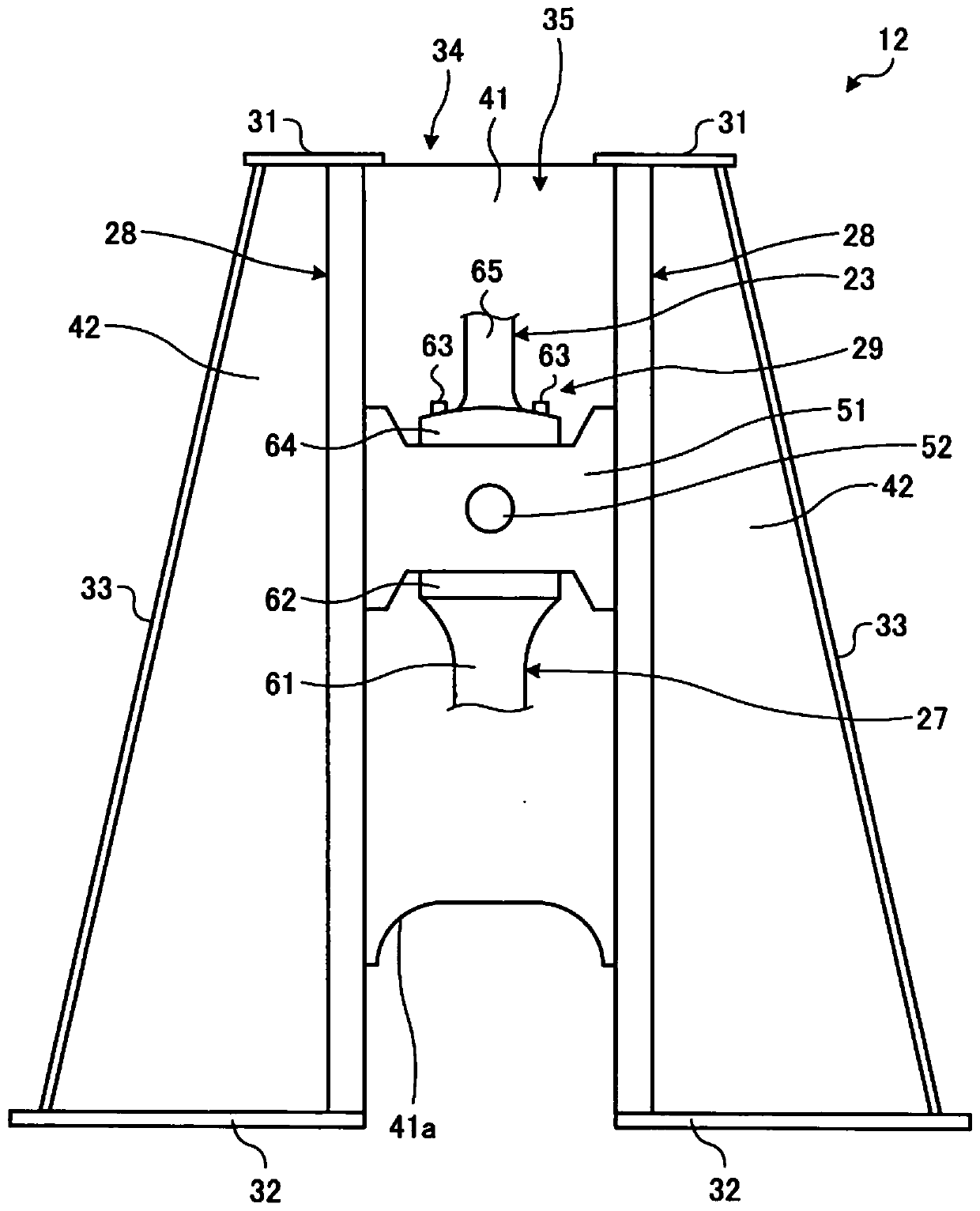

[0056] figure 1 It is a schematic diagram showing the diesel engine of the first embodiment.

[0057] In the first embodiment, if figure 1 As shown, the diesel engine 10 is, for example, a two-stroke, one-cycle single-flow scavenging type crosshead internal combustion engine used as a main engine for propulsion of a ship. The diesel engine 10 has a base plate 11 located below, a frame 12 provided on the base plate 11 , and a cylinder cover 13 provided on the frame 12 . The base plate 11 , the frame 12 and the cylinder cover 13 are integrally fastened and fixed by a plurality of tie bolts (connection members) 14 and nuts 15 extending in the vertical direction.

[0058] The cylinder liner 16 is disposed in the cylinder cover 13 , and a space portion is defined by fixing the cylinder head 17 at the upper portion thereof, and the piston 18 is provided in the space portion so as to be able to reciprocate up and down. In addition, the cylinder head 17 is provided with an exhaust ...

no. 2 approach

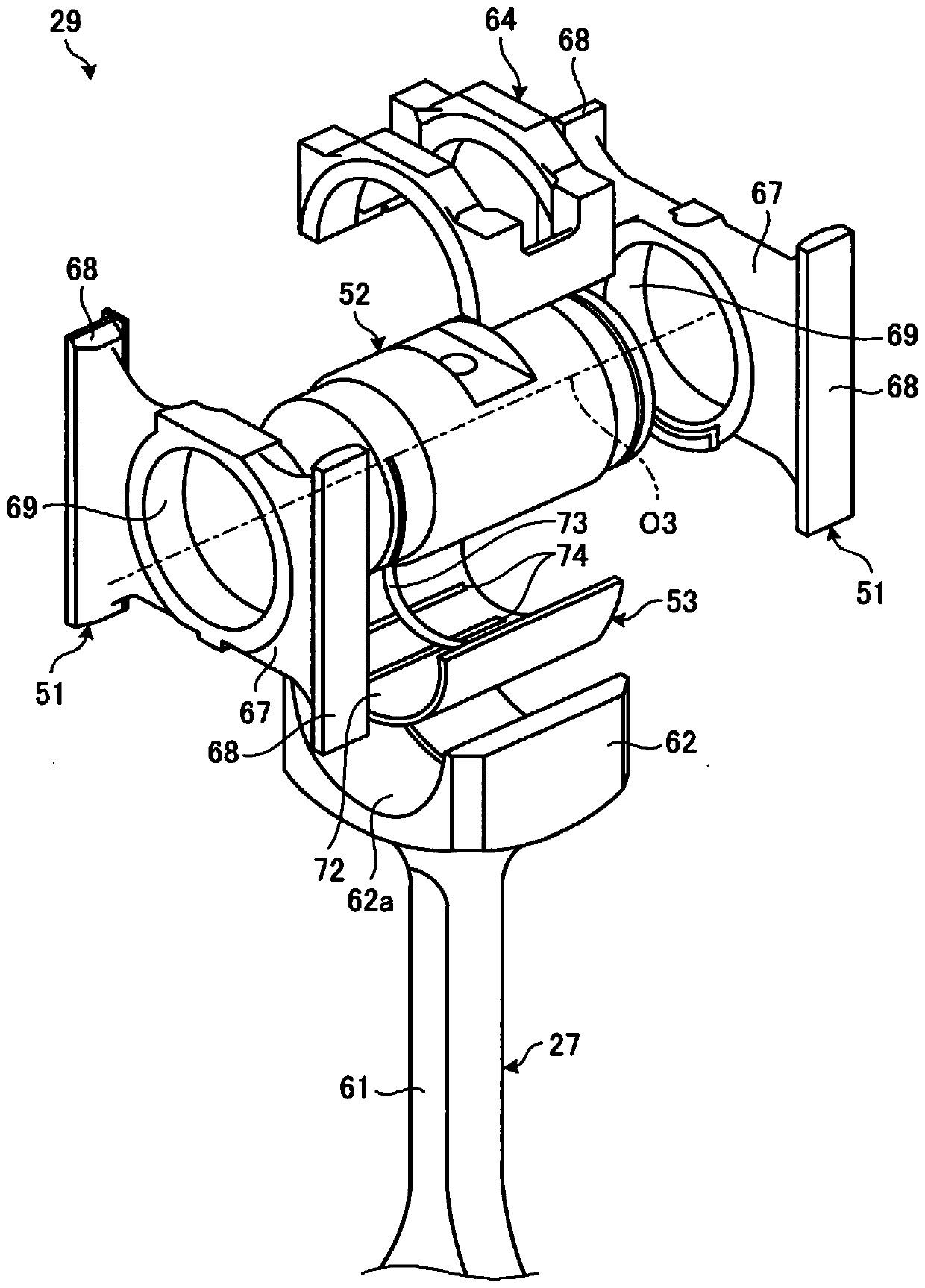

[0106] Figure 14 It is a plan view showing the crosshead of the second embodiment, Figure 15 yes Figure 14 XV-XV sectional view. In addition, the same code|symbol is attached|subjected to the component which has the same function as the above-mentioned embodiment, and detailed description is abbreviate|omitted.

[0107] In the crosshead of the second embodiment, as Figure 14 and Figure 15 As shown, a bearing (crosshead bearing) 101 includes a bearing main body 71 , a bearing surface 72 , an axial oil groove 74 , a slit opening (communicating portion) 102 , and an inclined groove (inclined portion) 103 .

[0108] The bearing shell 101 is provided with a plurality of axial oil grooves 74 at predetermined intervals in the circumferential direction C along the axial direction A on the bearing surface 72 . The bearing bush 101 is formed along the circumferential direction C with a slit opening 102 penetrating in the thickness direction. Lengthwise ends of the plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com