Straw deep burying and returning method and device

A straw and straw crushing technology, which is applied in shovel, agricultural gas emission reduction, plough and other directions, can solve the problems of uneven burial, affecting the growth of plants in the next season, and uneven straw.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing:

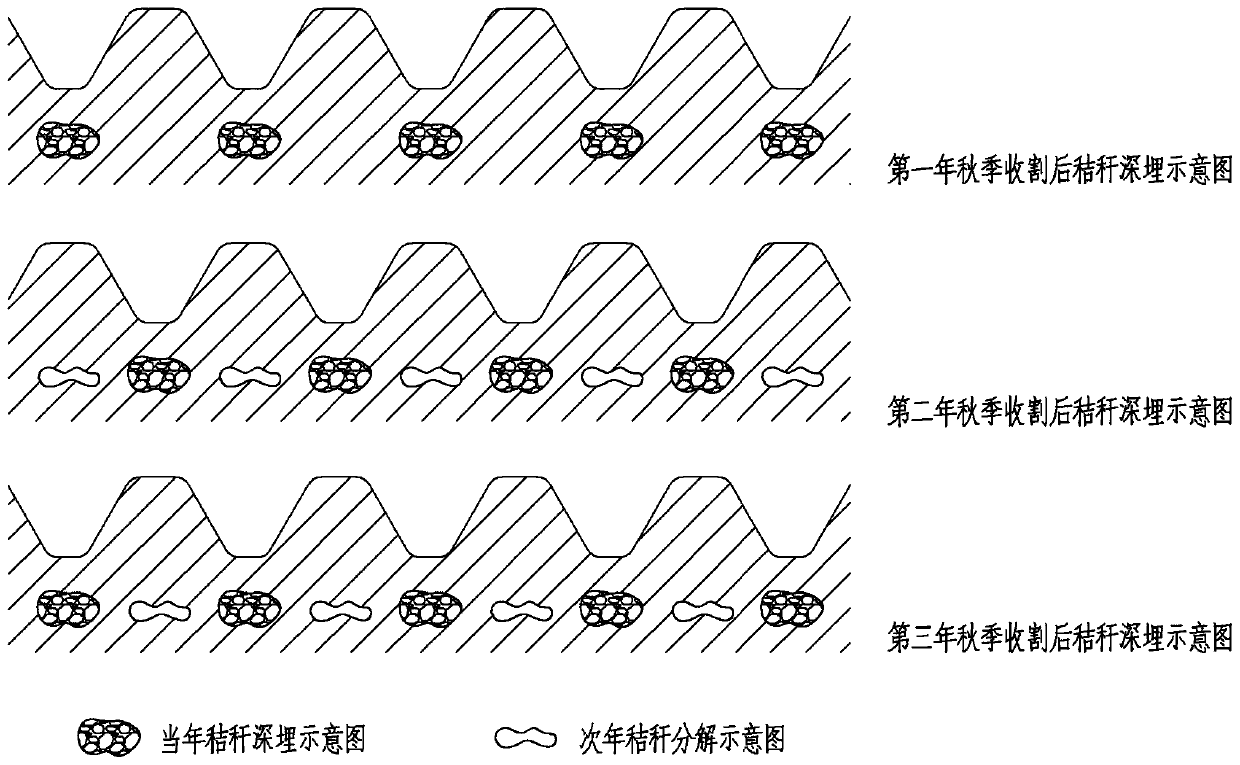

[0043] The technical solution of the present invention is: after harvesting, the ridge platform is broken to become a ridge, and the crushed straw is buried under the bottom soil layer of the ridge to become the pattern of the ridge for cultivation in the next season, which specifically includes the following steps:

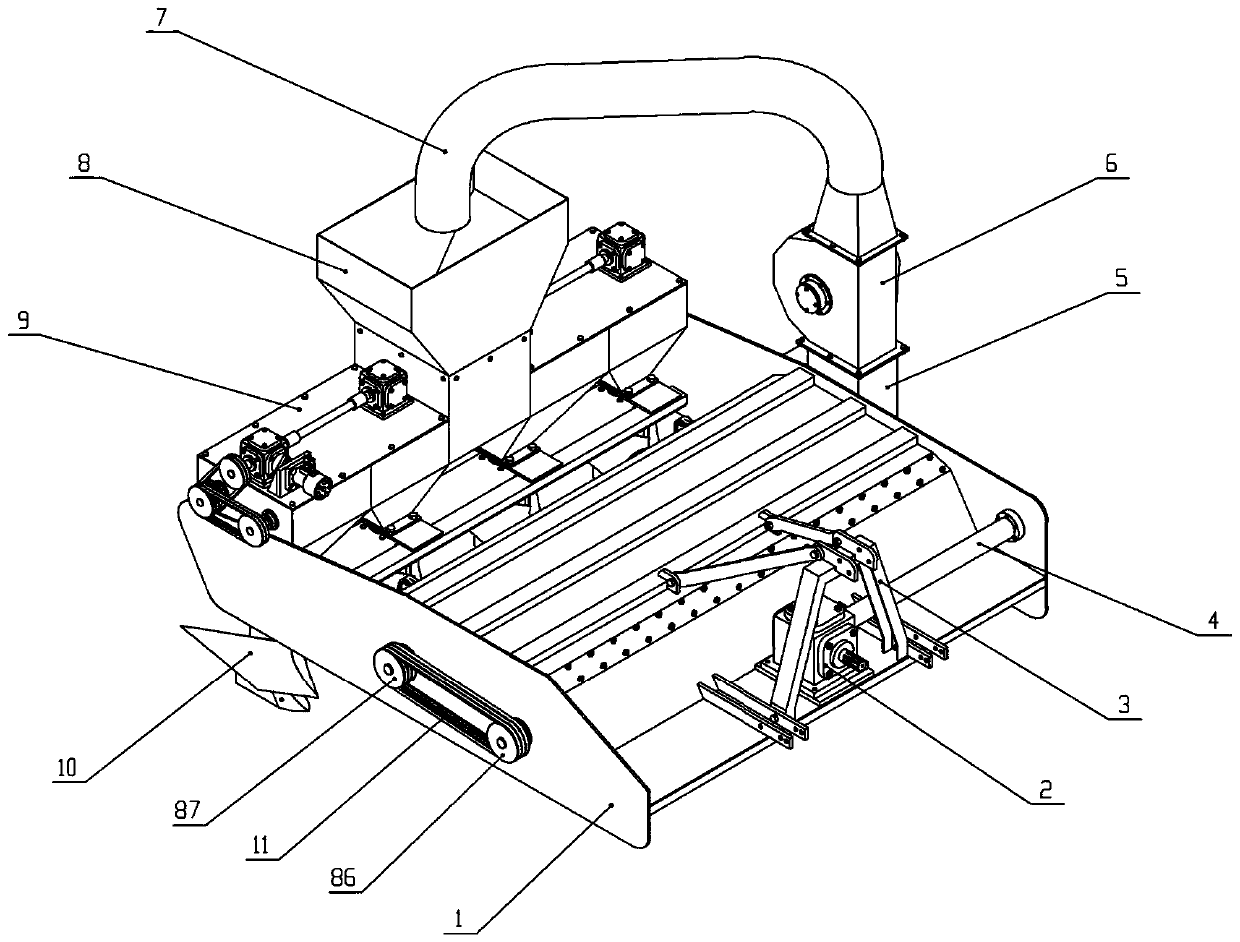

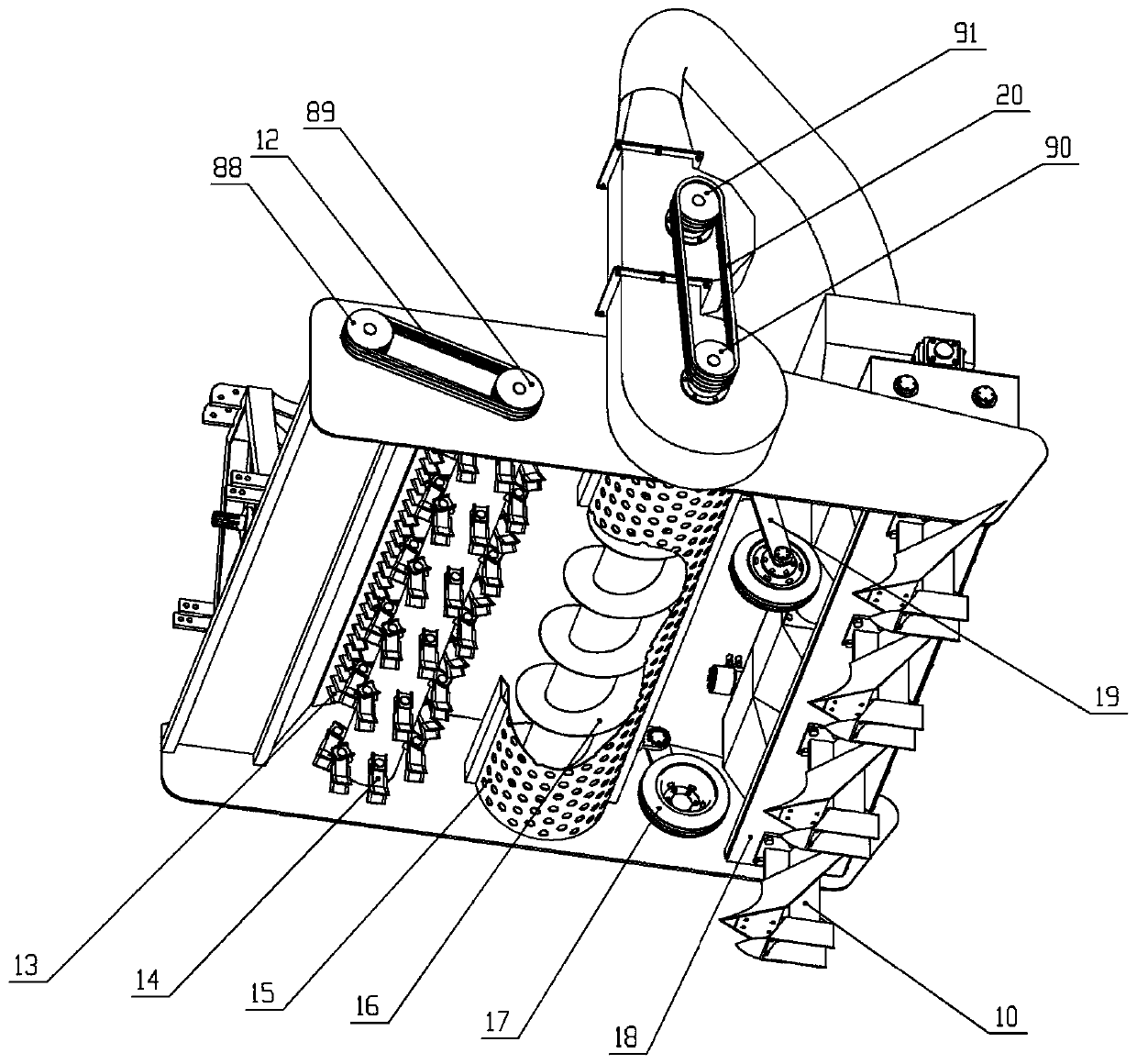

[0044] The first step is to use the power locomotive to pull the straw deep burying and returning device to carry out the picking and crushing procedure in the field; the picking and crushing procedure includes using the picking and crushing device in the device to pick up all the scattered straw in the farmland, including the stubble on the ridge. After crushing, throw it directly into the straw screw conveyor, and then send it to the storage box in the field returning device after being processed by a fan and a secondary pulverizer;

[0045] In the second st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com