Technology for rapidly processing sauce-stewed meat products based on concave electromagnetic induction pot

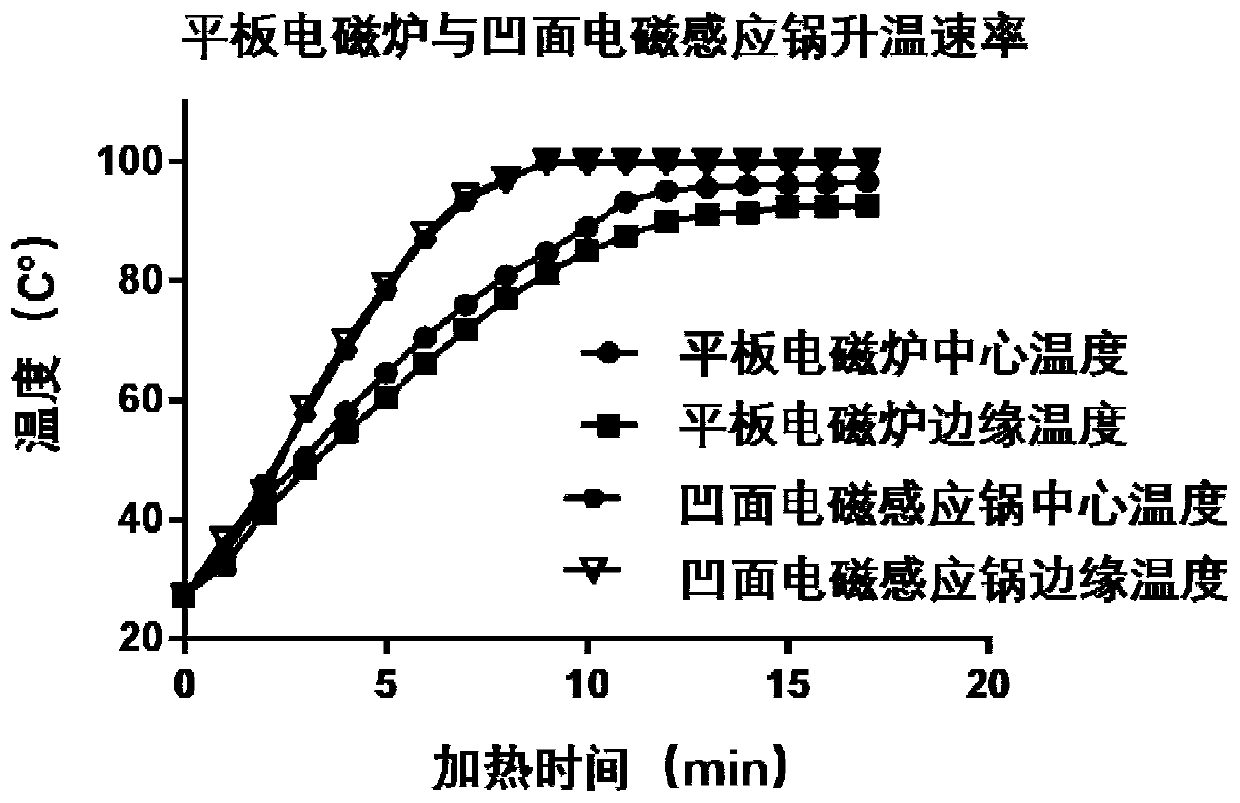

A technology of electromagnetic induction for stewed meat products, which is applied in food freezing, food science, etc., can solve the problems of poor flavor and texture of products, long processing time of stewed meat products, and low thermal efficiency of processing, so as to achieve large-scale industrialization The effect of rapid production, lower temperature and fast heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

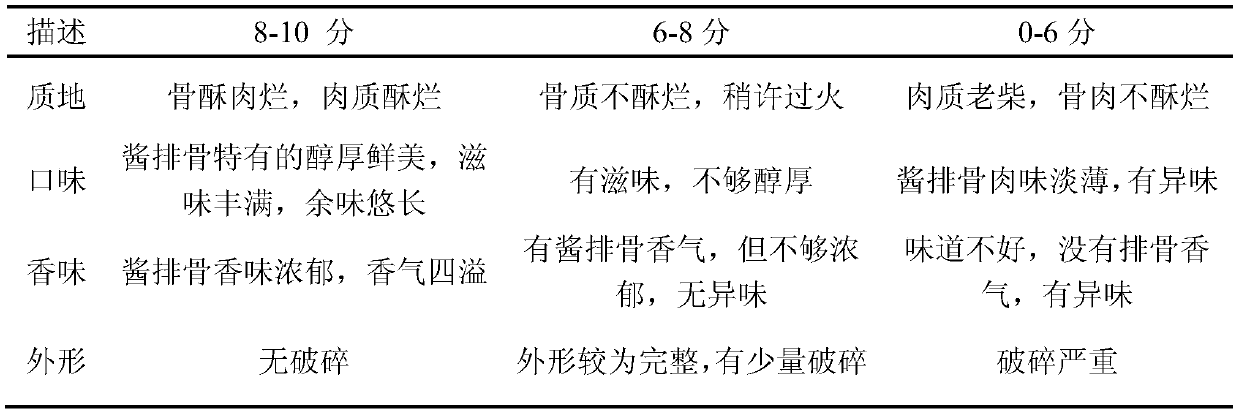

Examples

Embodiment 1

[0033] This embodiment provides a recipe and process for making sauce ribs conditioning packs based on a concave electromagnetic induction pot. The recipe is made of the following parts by weight of raw materials: 800 parts of pork ribs, 2 parts of fennel, 0.2 parts of cloves, 2 parts of cardamom, 2 parts cinnamon, 3 parts green onion powder, 5 parts ginger powder, 9 parts salt, 100 parts white sugar, 30 parts cooking wine, 30 parts dark soy sauce, 20 parts light soy sauce.

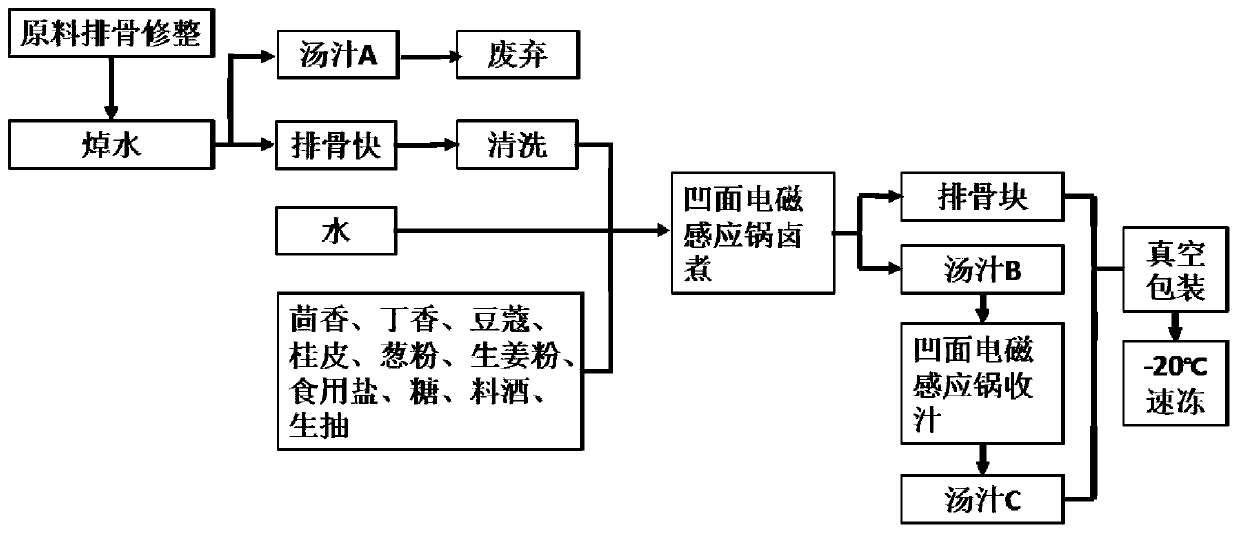

[0034] The sauce ribs are processed according to the above formula, and the processing technology includes the following steps:

[0035] (1) Pretreatment:

[0036] ① Trim and blanch raw pork ribs

[0037] Remove the excess fat on the surface of the pork ribs, cut them into pieces with a length of 4cm, and wash off the broken bones and blood stains on the surface with water; put the ribs in cold water and heat with 2000 power, when the center temperature of the pot is at the same temperature as the side of the pot...

Embodiment 2

[0047] Example 2 (Comparative cooking time group)

[0048] This embodiment provides a recipe and process for making sauce ribs conditioning packs based on a concave electromagnetic induction pot. The recipe is made of the following parts by weight of raw materials: 800 parts of pork ribs, 2 parts of fennel, 0.2 parts of cloves, 2 parts of cardamom, 2 parts cinnamon, 3 parts green onion powder, 5 parts ginger powder, 9 parts salt, 100 parts white sugar, 30 parts cooking wine, 30 parts dark soy sauce, 20 parts light soy sauce.

[0049] The sauce ribs are processed according to the above formula, and the processing technology includes the following steps:

[0050] (1) Pretreatment:

[0051] ① Trim and blanch raw pork ribs

[0052] Remove the excess fat on the surface of the pork ribs, cut them into pieces with a length of 4cm, and wash off the broken bones and blood stains on the surface with water; put the ribs in cold water and heat with 2000 power, when the center temperature of the po...

Embodiment 3

[0062] Example 3 (Traditional Process Comparison Group)

[0063] This embodiment provides a recipe and process for making sauced ribs conditioning packs based on a plate induction cooker. The recipe is made of the following parts by weight: 800 parts of pork ribs, 2 parts of fennel, 0.2 parts of cloves, 2 parts of cardamom, and 2 parts of cinnamon. Servings, 3 scallion powder, 5 ginger powder, 9 edible salt, 100 sugar, 30 cooking wine, 30 dark soy sauce, 20 light soy sauce.

[0064] The processing technology includes the following steps:

[0065] (1) Pretreatment:

[0066] ① Trim and blanch raw pork ribs

[0067] Remove the excess fat on the surface of the pork ribs, cut them into 4 pieces, wash off the broken bones and blood stains on the surface with water; put the ribs into cold water, use a plate induction cooker with 2000 power, when the center temperature of the pot is at When the temperature is 95℃, blanch the water for 5 minutes;

[0068] (2) Boiled in plate induction cooker:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com