Production method of high-quality pseudo-ginseng decoction pieces

A production method and high-quality technology, applied in pharmaceutical formulations, medical preparations containing active ingredients, plant raw materials, etc., can solve problems such as high safety risks, easy damage, and uneven quality of Panax notoginseng medicinal materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

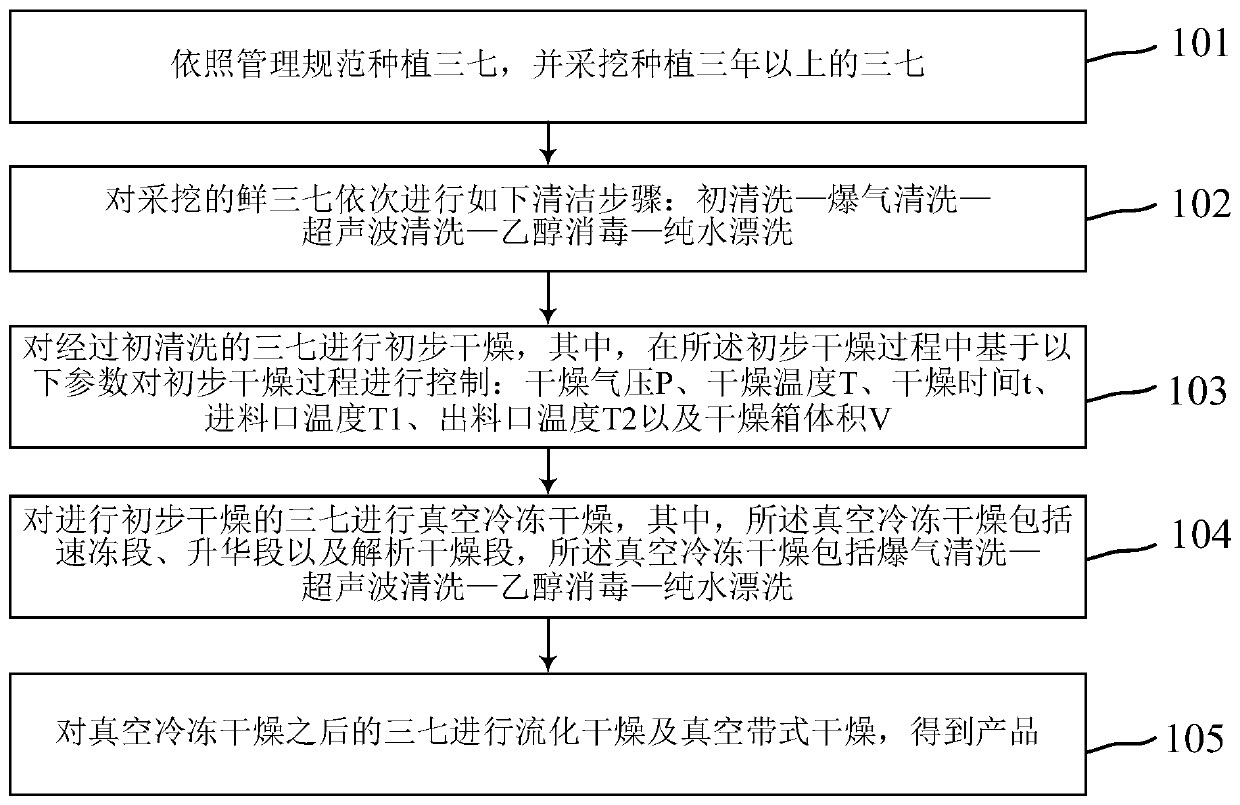

[0036] The production method of high-quality Panax notoginseng decoction pieces includes the following steps: the excavated fresh Panax notoginseng is cleaned in sequence by the following steps: initial cleaning-gas explosion cleaning-ultrasonic cleaning-ethanol disinfection-pure water rinsing; Preliminary drying, wherein, in the preliminary drying process, the preliminary drying process is controlled based on the following parameters: drying air pressure P, drying temperature T, drying time t, inlet temperature T1, outlet temperature T2 and drying box volume V Carry out vacuum freeze-drying to the Radix Notoginseng that carries out primary drying, wherein, described vacuum freeze-drying comprises quick-freezing section, sublimation section and analysis drying section, and described vacuum freeze-drying comprises explosion cleaning-ultrasonic cleaning-alcohol disinfection-pure water rinsing Among them, the quick-freezing section specifically includes the following steps: put th...

Embodiment 2

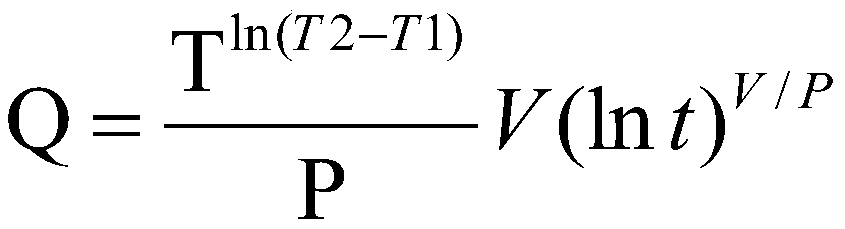

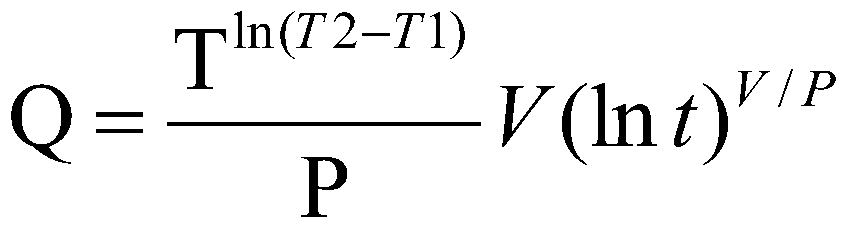

[0040] Based on drying air pressure P, drying temperature T, drying time t, inlet temperature T1, outlet temperature T2 and drying box volume V, the control of the preliminary drying process specifically includes the following steps: monitoring drying air pressure P, drying temperature T , drying time t, inlet temperature T1, outlet temperature T2, and drying box volume V to calculate the Q value, if the Q value is lower than the quality threshold, the following operations are performed: monitor the drying air pressure P, and if it is expected to reduce the air pressure P to If the lower air pressure limit still cannot make the Q value meet the quality threshold, then monitor the drying temperature T; if the drying temperature T is greater than the lower temperature limit and less than the upper temperature limit, increase the drying temperature T. Other steps are the same as in Example 1.

Embodiment 3

[0042] Based on drying air pressure P, drying temperature T, drying time t, inlet temperature T1, outlet temperature T2 and drying box volume V, the control of the preliminary drying process specifically includes the following steps: monitoring drying air pressure P, drying temperature T , drying time t, inlet temperature T1, outlet temperature T2, and drying box volume V to calculate the Q value, if the Q value is lower than the quality threshold, the following operations are performed: monitor the drying air pressure P, and if it is expected to reduce the air pressure P to If the lower limit of air pressure still cannot make the Q value meet the quality threshold, then monitor the drying temperature T; monitor the drying temperature T, if it is expected to increase the drying temperature T to the upper temperature limit and still cannot make the Q value meet the quality threshold, then monitor the drying time t; if the drying time t If it is greater than the lower time limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com