Preparation method of spherical carbon-coated nickel with different carbon layers and hydrogen evolution property for water electrolysis of spherical carbon-coated nickel

A carbon-coated nickel and spherical technology, which is applied in the field of transition metal carbide preparation, can solve the problems of unfavorable promotion, time-consuming, cumbersome process, etc., and achieve the effects of reducing production costs, simple equipment requirements, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Preparation of spherical carbon-coated nickel with 1 to 4 layers of carbon

[0026] Weigh 0.225g (0.15mol / L) glycine and 1.073g (0.225mol / L) nickel nitrate hexahydrate into a beaker filled with 20mL of absolute ethanol, stir magnetically for 2h, and transfer the supernatant to polytetrafluoroethylene In a high-temperature and high-pressure autoclave, react at 180°C for 12h, wash with ethanol after cooling, and dry at 60°C to obtain a green powder. Calcined at 450°C for 3h under nitrogen atmosphere, increasing 5°C per minute.

Embodiment 2

[0027] Embodiment 2: Preparation of spherical carbon-coated nickel with 5-8 layers of carbon

[0028] Weigh 0.255g (0.167mol / L) glycine and 1.274g (0.267mol / L) nickel nitrate hexahydrate into a beaker filled with 25mL absolute ethanol, stir magnetically for 2 hours, and transfer them all to polytetrafluoroethylene under high temperature and high pressure In the kettle, react at 180°C / 12h, wait for cooling, wash with ethanol suction filtration, and dry at 60°C to obtain a green powder. Calcined at 500°C for 3h under nitrogen atmosphere, increasing 5°C per minute.

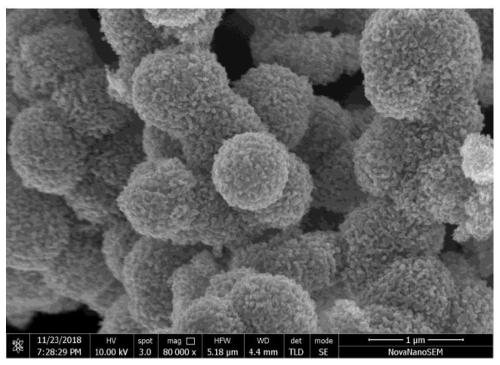

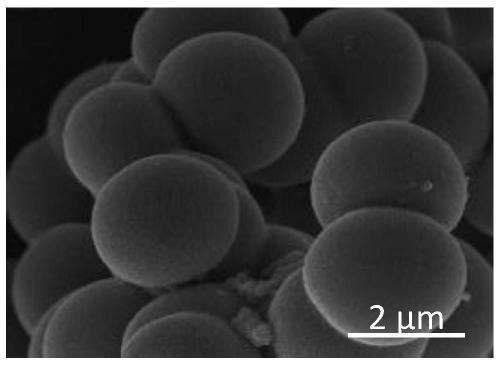

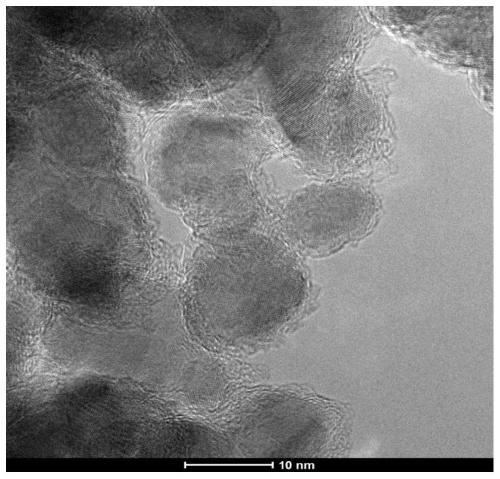

[0029] The scanning electron microscope picture and the transmission electron microscope picture of the spherical carbon-coated nickel of above embodiment 1 and 2 synthesis are as Figure 1~4 As shown, and according to the picture, it can be seen that the diameter of the nanospheres is uniform, about 2 μm, and the diameter of a single carbon-coated nickel is about 10 nm.

[0030] And to the spherical carbon-coated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com