Preparation method of super-hydrophobic non-iridescence structural color film

A super-hydrophobic, structural color technology, used in devices, coatings, special surfaces, etc. that apply liquid to the surface, can solve the problems of limited use, poor water resistance, poor weather resistance, etc., to improve color saturation, application Broad, hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a highly saturated non-iridescent structural color film with superhydrophobic properties, comprising the following steps:

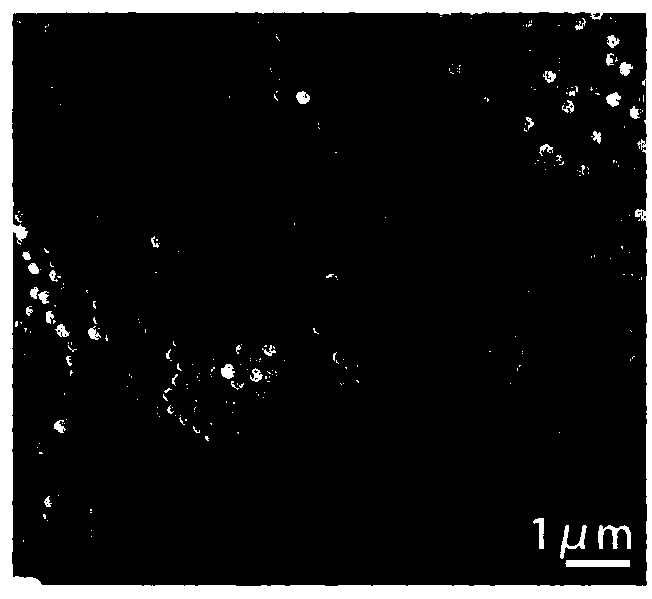

[0034] SiO with a diameter of 232nm 2 Disperse in ethanol, prepare the ethanol dispersion liquid that mass fraction is 10%, add mass accounted for SiO2 to dispersion liquid 2 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane with 3% mass of colloidal spheres was magnetically stirred at room temperature for 30 minutes to fully mix the suspension. The suspension was placed in a 40°C water bath for hydrophobic treatment for 10 hours. Finally, the fluorinated SiO 2 Collected by centrifugation at 6000rpm for 15 minutes. Disperse graphene with a particle size of 5 μm in ethanol to prepare a 0.8mg / ml ethanol dispersion, and then use an ultrasonic cell pulverizer to ultrasonically treat it at 650w, 25KHz for 30 minutes to ensure that graphene can be fully dispersed in ethanol solution. Graphene ethanol suspension. The above fluorinat...

Embodiment 2

[0036] SiO with a diameter of 267 nm 2 Disperse in ethanol, prepare the ethanol dispersion liquid that mass fraction is 10%, add mass accounted for SiO2 to dispersion liquid 2 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane with 3% mass of colloidal spheres was magnetically stirred at room temperature for 30 minutes to fully mix the suspension. The suspension was placed in a 40°C water bath for hydrophobic treatment for 10 hours. Finally, the fluorinated SiO 2 Collected by centrifugation at 6000rpm for 15 minutes. Disperse graphene with a particle size of 5 μm in ethanol to prepare a 0.8mg / ml ethanol dispersion, and then use an ultrasonic cell pulverizer to ultrasonically treat it at 650w, 25KHz for 30 minutes to ensure that graphene can be fully dispersed in ethanol solution. Graphene ethanol suspension. The above fluorinated SiO2 Colloidal microspheres, SiO 2 The mass fraction of the colloidal microspheres is 0.6% graphene ethanol suspension dispersed in the ethanol soluti...

Embodiment 3

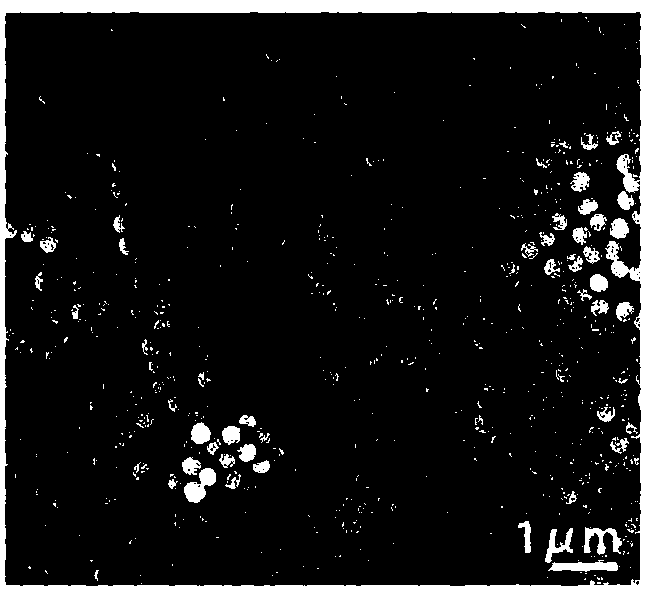

[0038] SiO with a diameter of 317 nm 2 Disperse in ethanol, prepare the ethanol dispersion liquid that mass fraction is 10%, add mass accounted for SiO2 to dispersion liquid 2 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane with 3% mass of colloidal spheres was magnetically stirred at room temperature for 30 minutes to fully mix the suspension. The suspension was placed in a 40°C water bath for hydrophobic treatment for 10 hours. Finally, the fluorinated SiO 2 Collected by centrifugation at 6000rpm for 15 minutes. Disperse graphene with a particle size of 5 μm in ethanol to prepare a 0.8mg / ml ethanol dispersion, and then use an ultrasonic cell pulverizer to ultrasonically treat it at 650w, 25KHz for 30 minutes to ensure that graphene can be fully dispersed in ethanol solution. Graphene ethanol suspension. The above fluorinated SiO 2 Colloidal microspheres, SiO 2 The mass fraction of the colloidal microspheres is 0.6% graphene ethanol suspension dispersed in the ethanol solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Reflection wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com