S-shaped belt conveyer adopting modular joint unit

A technology of modular joints and serpentine belts, which is applied in the direction of conveyors, conveyor objects, earthwork drilling and mining, etc., can solve the problems of high risk factor, harsh working environment, and low work efficiency, so as to increase the bearing capacity of idlers, Easy to groove and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiments, and the advantages and characteristics of the present invention will become clearer along with the description. However, these embodiments are only exemplary and do not constitute any limitation to the scope of the present invention. Those skilled in the art should understand that the details and forms of the technical solutions of the present invention can be modified or replaced without departing from the spirit and scope of the present invention, but these modifications and replacements all fall within the protection scope of the present invention.

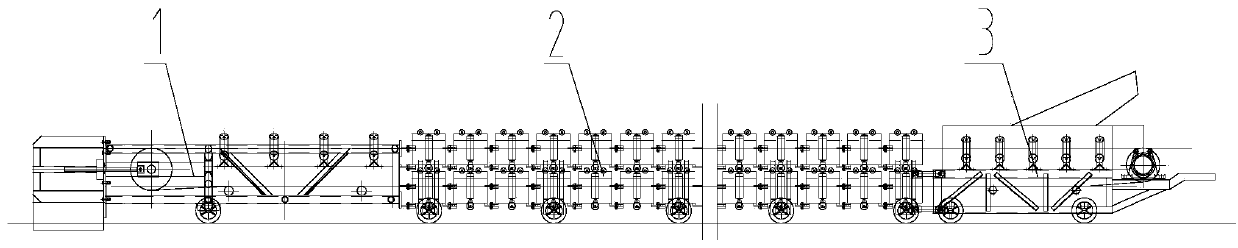

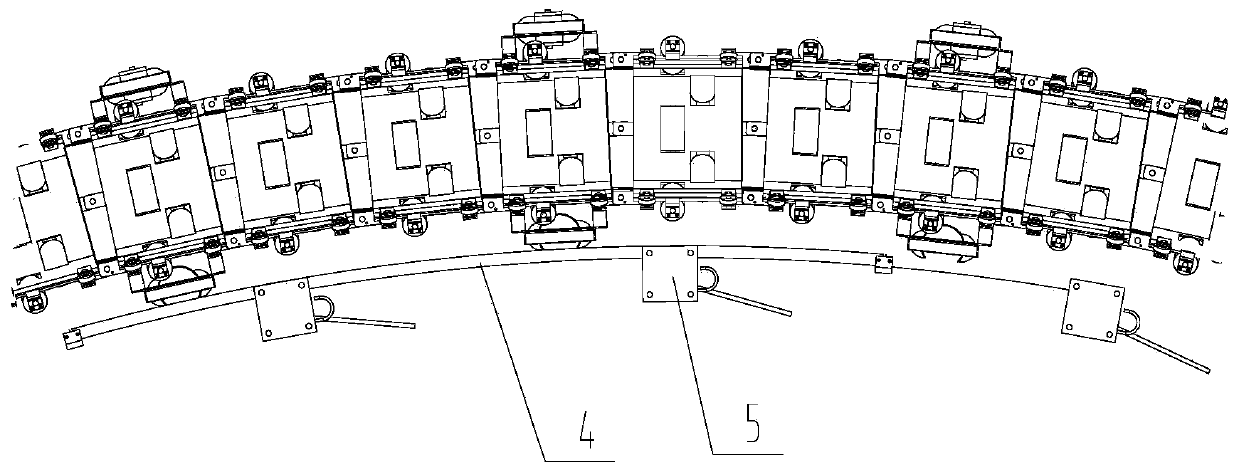

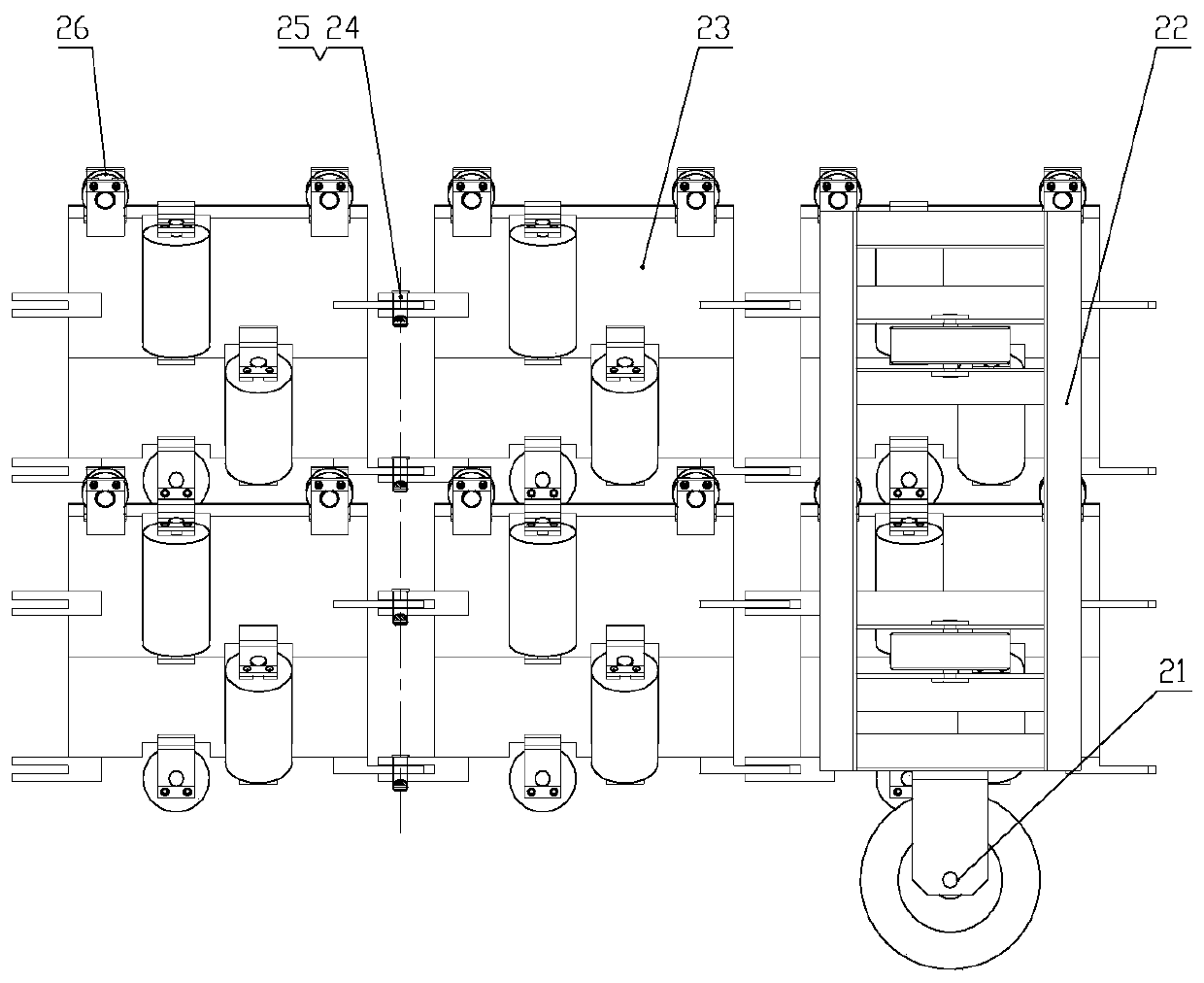

[0025] see Figure 1 to Figure 7 , the present invention relates to a serpentine belt conveyor using a modular joint unit, including a body, the body includes a head 1, a middle section 2 and a tail 3, the head 1, the middle part 2 and the machine The tail 3 is sequentially connected by pin shaft rotation; the support rod 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com