Detection method for determining chloride ion content in sea sand

A technology of chloride ion content and detection method, which is applied in the detection field of determining the chloride ion content in sea sand, can solve the problems of endangering the structural safety of buildings, difficulty in correcting detection errors, and increasing experimental errors, so as to shorten the detection time and reduce the detection time. Error, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

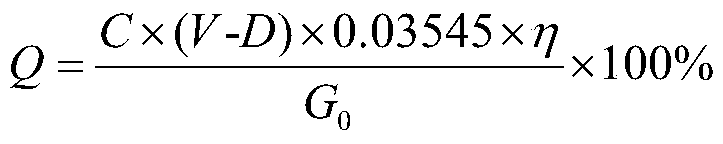

[0035] A kind of detection method of determining chloride ion content in the sea sand in the embodiment, carries out as follows:

[0036] Step 1: preparing the washing filtrate;

[0037] Take the sea sand sample to be tested and dry it to constant weight, then weigh the mass as G 0 The dried sea sand sample to be tested is then added to boiled deionized water and stirred for 3-6 minutes, then left to stand for 10-15 minutes, and then filtered to obtain washed sea sand and water-washed filtrate; during the stirring process, the deionized water is maintained by heating The temperature is not lower than 90°C; the mass ratio of the dried sea sand sample to be tested for mixing and stirring to the deionized water is 1:1.5-2.5;

[0038] Step 2: preparing powder filtrate;

[0039] After drying the washed sea sand obtained in step 1 until the surface is dry, grind the washed sea sand into sea sand powder with a fineness of not less than 100 mesh, then add the sea sand powder into de...

Embodiment 1

[0063] Pour 400g of the sea sand sample to be tested that has been dried to constant weight into 800ml of boiled deionized water, and use a magnetic stirrer with a rotation speed of 1000r / min to fully stir for 5min. During the stirring process, keep heating to keep the temperature of the deionized water at 92°C , the stirring was completed, and filtered after standing for 12 minutes to obtain washed sea sand and 580ml washed filtrate. After drying the washed sea sand in a drying oven until the surface is dry, use a ball mill to grind the washed sea sand into sea sand powder with a fineness of 100 mesh, pour the sea sand powder into 800ml of deionized water and stir for 10 minutes, then filter to obtain 520ml powder filtrate. After placing the water-washed filtrate and powder filtrate in a 30°C incubator for 20 minutes, measure 290ml of water-washed filtrate and 260ml of powder filtrate and mix and stir to obtain 550ml of mixed filtrate; place the mixed filtrate, water-washed f...

example 1

[0066] Calculate the chloride ion content in sea sand using the test method in GB / T 14684-2011 "Sand for Construction". Take 1000g of the sea sand sample from the same source as in the above application example 1, place it in a drying oven and dry it to constant weight, and then cool it for later use; weigh 500g of dry sand and pour it into a ground-mouth bottle, and inject 500mL of distilled water into the ground-mouth bottle, Cover the stopper, shake it once and let it stand for 2 hours, then shake it once every 5 minutes, and shake it 3 times in total; after filtering the solution, carry out two silver nitrate titration methods to measure the chloride ion content, and calculate the arithmetic mean of the two test results to get the chloride ion The content is 0.135%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com