Tilapia fresh-keeping method

A fresh-keeping method, tilapia technology, applied in the direction of preserving meat/fish with chemicals, preserving meat/fish through freezing/cooling, preserving meat/fish through radiation/electrical treatment, etc., which can solve incomplete sterilization and deterioration , secondary pollution of fish and other issues, to achieve the effect of enriching sales types, reducing energy consumption, and high market practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The fresh-keeping method of present embodiment is as follows:

[0043](1) Raw material pretreatment: take live fish, slaughter, remove fish scales, internal organs, fish skin, fish bones, obtain fish meat, weigh, grade into 3-5 ounces, wash and drain, and arrange on a plate;

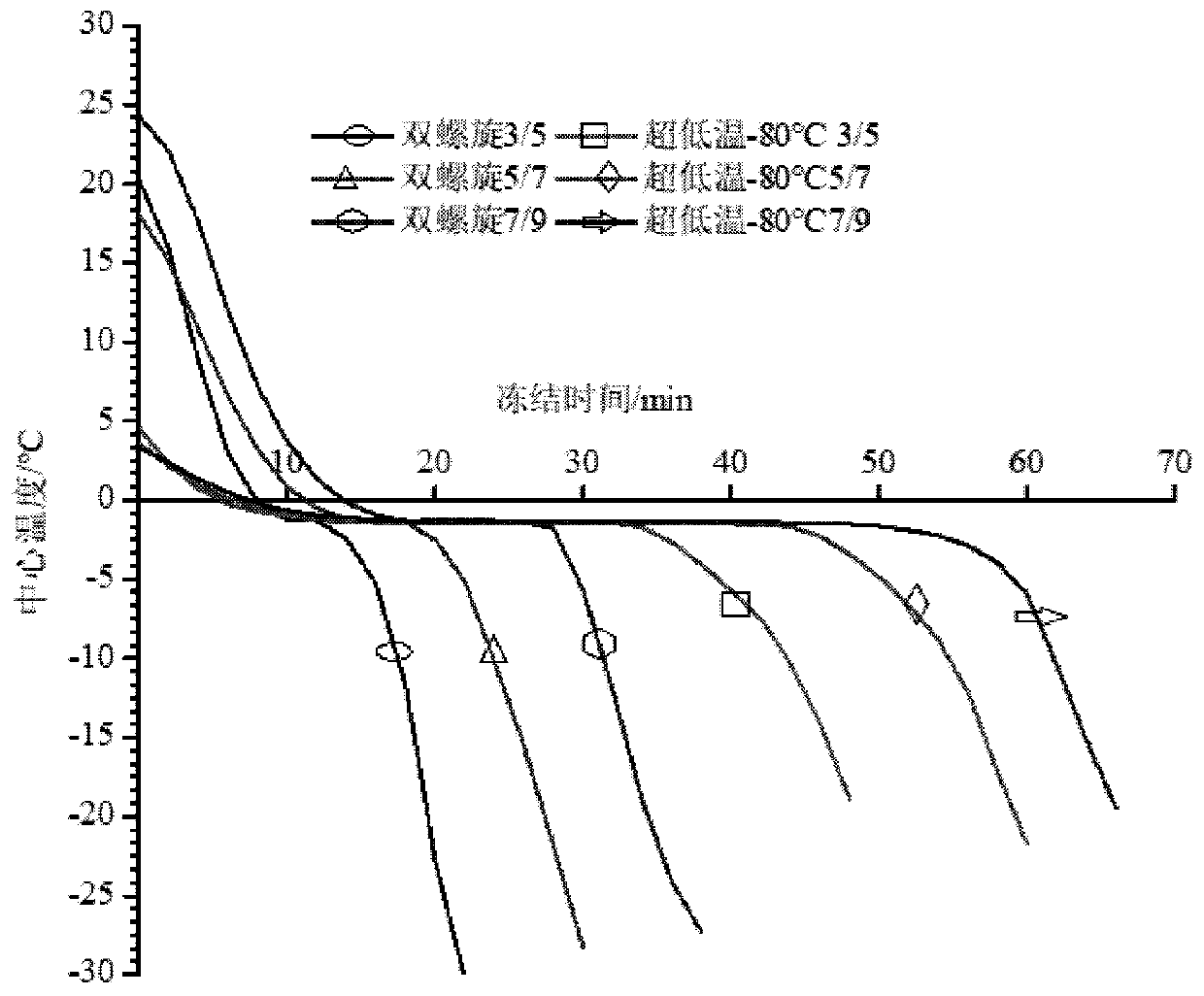

[0044] (2) Quick-freeze the fish fillets with the ultra-low temperature of -80°C and quick-freeze to the corresponding central temperature of -8°C.

[0045] (3) Modified atmosphere packaging

[0046] The micro-frozen fish fillets obtained in step (2) are inflated and packaged with a modified atmosphere fresh-keeping machine, and the packaging material is tray: HS-7PP; sealing film: pp50um

[0047] Inflation parameters: Inflation time 30ms, sealing temperature 160°C. Filled with carbon dioxide, nitrogen, oxygen, CO 2 Volume content is 40%, N 2 Volume content is 30%, O 2 The volume content is 30%, and the inflated amount is determined by the tray and the inflated time;

[0048] (4) Low tempera...

Embodiment 2

[0055] The fresh-keeping method of present embodiment is as follows:

[0056] (1) Raw material pretreatment: take live fish, slaughter, remove fish scales, internal organs, fish skin, fish bones, obtain fish meat, weigh, grade 3-5 ounces, wash and drain, and arrange on a plate;

[0057] (2) The fish fillets are frozen at ultra-low temperature of -80°C, and the standard fish fillets are quickly frozen to a corresponding central temperature of -8°C.

[0058] (3) Modified atmosphere packaging

[0059] The micro-frozen fish fillets obtained in step (2) are inflated and packaged with a modified atmosphere fresh-keeping machine, and the packaging material is tray: HS-7PP; sealing film: pp50um

[0060] Inflation parameters: Inflation time 30ms, sealing temperature 160°C. Filled with carbon dioxide, nitrogen, oxygen, CO 2 Volume content is 50%, N 2 Volume content is 30%, O 2 The volume content is 20%, and the amount of inflation is determined by the tray and inflation time;

[0...

Embodiment 3

[0068] The fresh-keeping method of present embodiment is as follows:

[0069] (1) Raw material pretreatment: take live fish, slaughter, remove fish scales, internal organs, fish skin, fish bones, obtain fish meat, weigh, grade into 3-5 ounces, wash and drain, and arrange on a plate;

[0070] (2) Use the ultra-low temperature of -80°C to freeze the fish fillets to the corresponding central temperature of -8°C.

[0071] (3) Modified atmosphere packaging

[0072] The slightly frozen fish fillets obtained in step (2) are inflated and packaged with a modified atmosphere fresh-keeping machine, and the packaging material is a tray: HS-7PP; sealing film: pp50um;

[0073] Inflation parameters: Inflation time 30ms, sealing temperature 160°C. Filled with carbon dioxide, nitrogen, oxygen, CO 2 Volume content is 60%, N 2 Volume content is 30%, O 2 The volume content is 10%, and the inflation volume is determined by the tray and inflation time;

[0074] (4) Low temperature plasma ster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com