Steel slag/nitrogen-doped activated carbon composite material, and preparation method and application thereof

A composite material and activated carbon technology, which is applied in catalyst activation/preparation, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of difficult catalyst recovery, large amount of sludge, narrow pH operation window, etc., and achieve easy surface properties, Promote degradation and improve the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

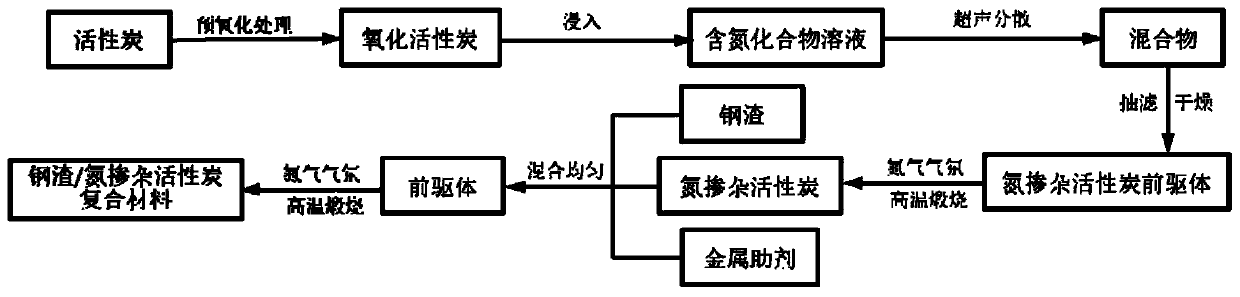

Method used

Image

Examples

Embodiment 1

[0028] A kind of steel slag / nitrogen-doped activated carbon composite material, the composite material in the present embodiment is made through the following steps:

[0029] S1: Immerse commercial powdered coal-based activated carbon in a nitric acid solution with a concentration of 1mol / L, and stir at a constant temperature of 60°C for 3 hours; then filter with suction, wash the filter residue with deionized water until it is neutral, and then put the filter residue into an oven Dry at a temperature of 50°C to obtain oxidized activated carbon.

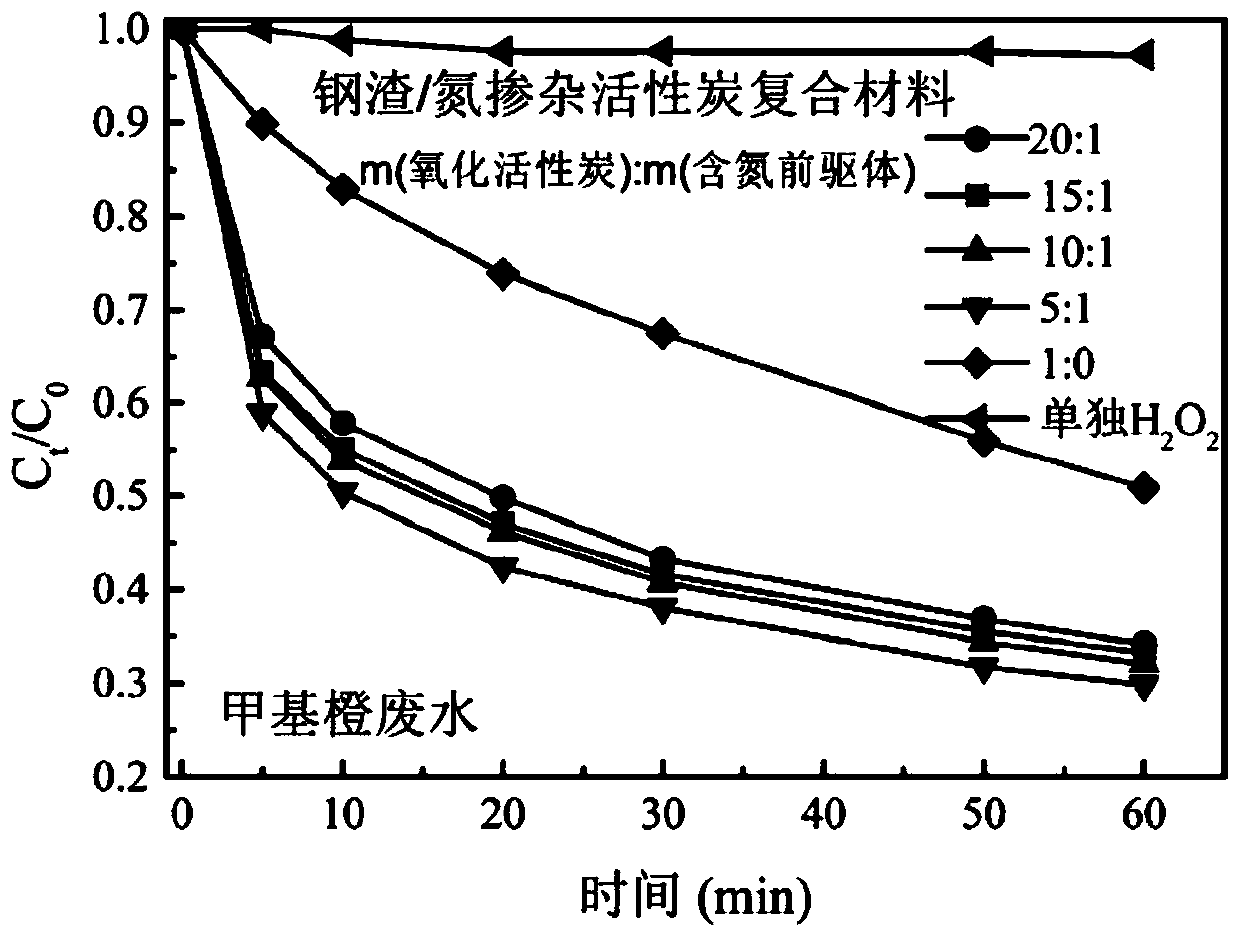

[0030] S2: According to the mass ratio of oxidized activated carbon to nitrogen-containing compound is 1:0, 5:1, 10:1, 15:1 and 20:1, immerse oxidized activated carbon in the corresponding melamine solution and ultrasonically disperse at a frequency of 30KHz for 6h , followed by suction filtration, and the filter residue was dried in an oven at a temperature of 60°C to obtain five nitrogen-doped activated carbon precursors.

[0031]...

Embodiment 2

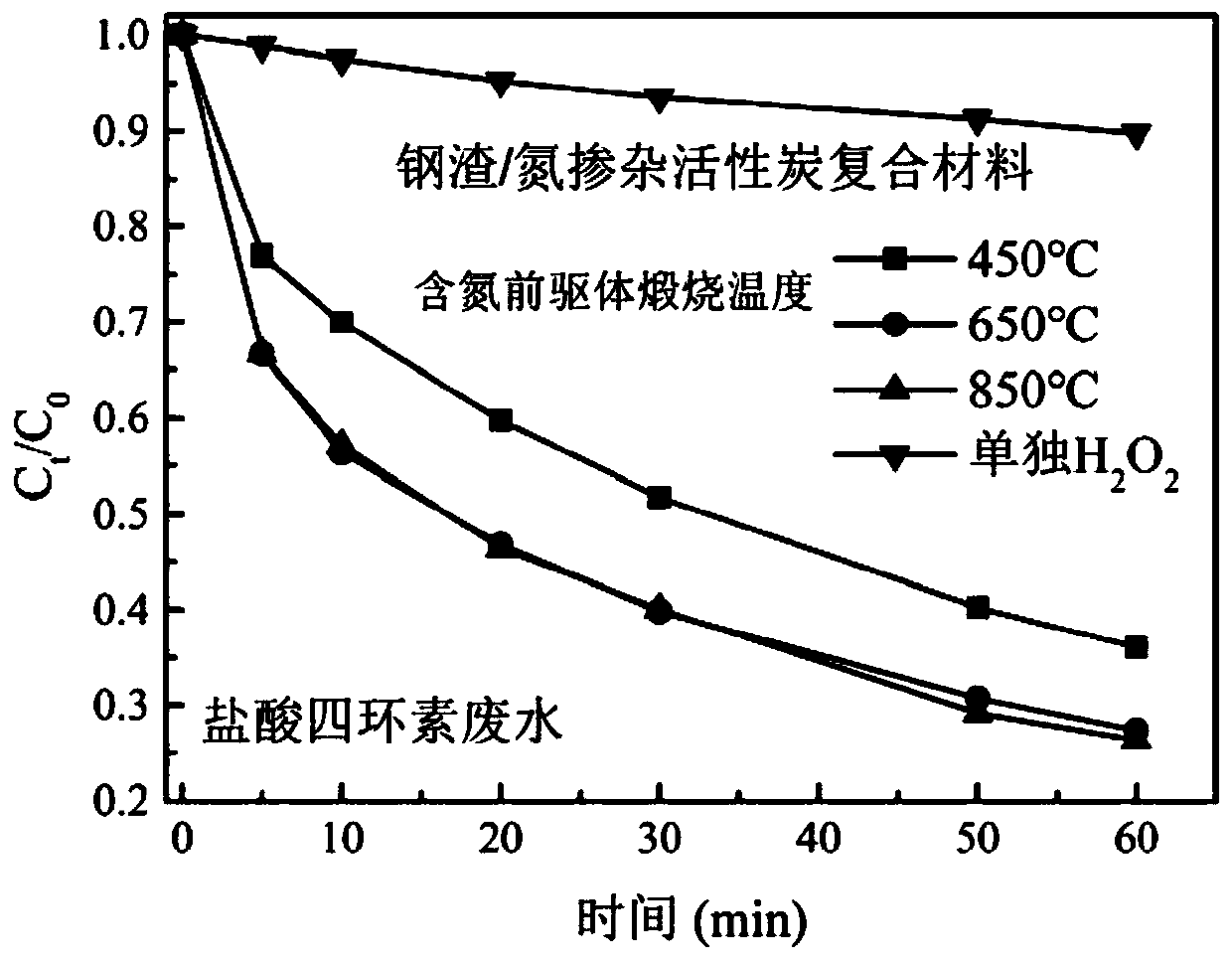

[0035] A kind of steel slag / nitrogen-doped activated carbon composite material, the composite material in the present embodiment is made through the following steps:

[0036] S1: Immerse commercial powdered wood-based activated carbon in a nitric acid solution with a concentration of 1mol / L, and stir at a constant temperature of 60°C for 3 hours; then filter with suction, and wash the filter residue with deionized water until neutral, then put the filter residue in an oven for use Dry at a temperature of 50°C to obtain oxidized activated carbon.

[0037] S2: According to the mass ratio of oxidized activated carbon to nitrogen-containing compound of 10:1, immerse oxidized activated carbon in the corresponding dipolycyanamide solution and ultrasonically disperse at a frequency of 30kHz for 6h, then suction filter, and put the filter residue in an oven for use Dry at a temperature of 60°C to obtain a nitrogen-doped activated carbon precursor.

[0038] S3: The nitrogen-doped activa...

Embodiment 3

[0042] A kind of steel slag / nitrogen-doped activated carbon composite material, the composite material in the present embodiment is made through the following steps:

[0043] S1: Immerse commercial powdered coconut shell-based activated carbon in a nitric acid solution with a concentration of 1mol / L, and stir at a constant temperature of 60°C for 3 hours; then filter with suction, wash the filter residue with deionized water until it is neutral, and then put the filter residue in an oven Dry at a temperature of 50°C to obtain oxidized activated carbon.

[0044] S2: According to the mass ratio of oxidized activated carbon to nitrogen-containing compound is 5:1, immerse oxidized activated carbon in the corresponding urea solution and ultrasonically disperse at a frequency of 30kHz for 6h, then suction filter, and put the filter residue in an oven with a temperature of 60°C. Dry at high temperature to obtain nitrogen-doped activated carbon precursor.

[0045] S3: The nitrogen-do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com