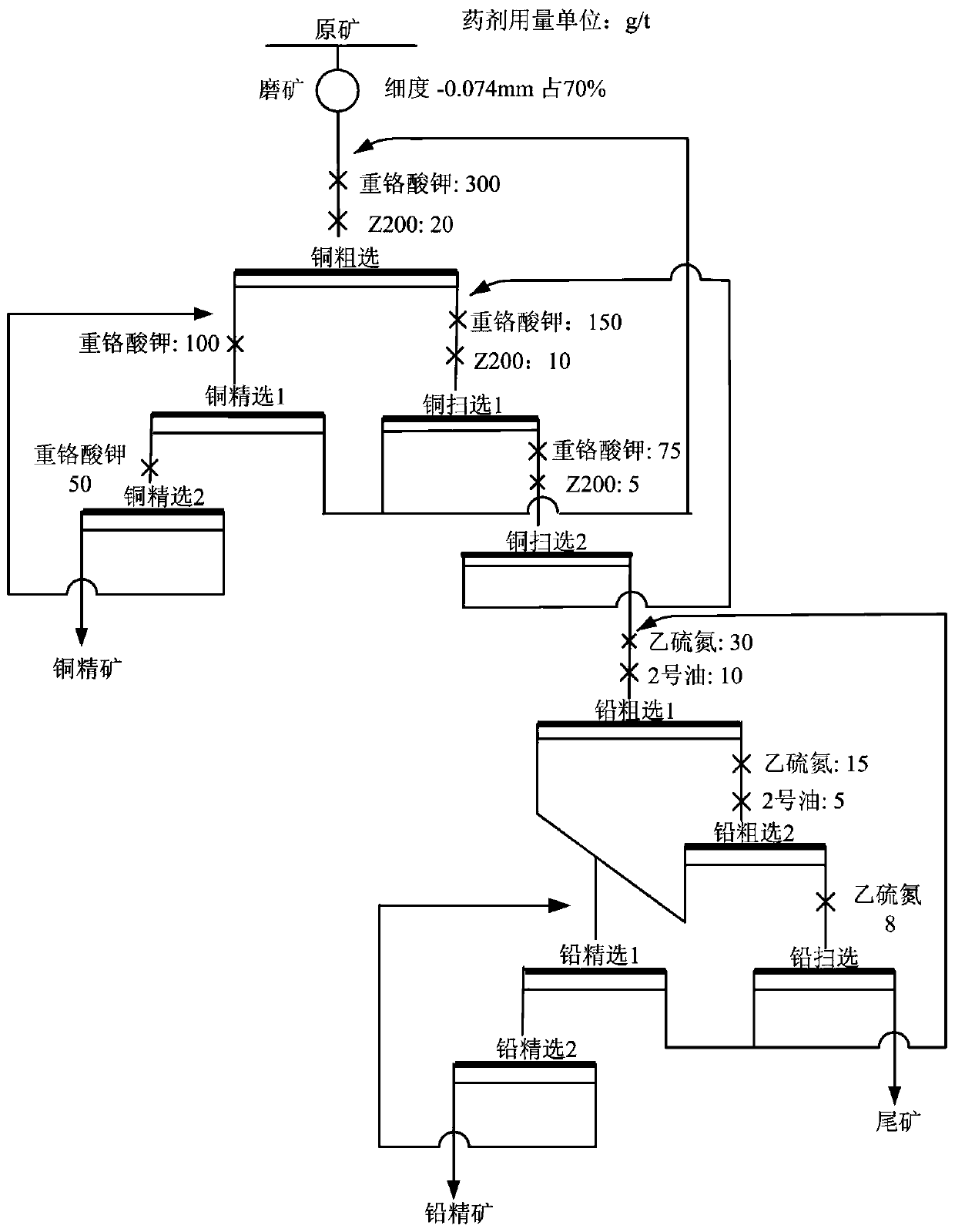

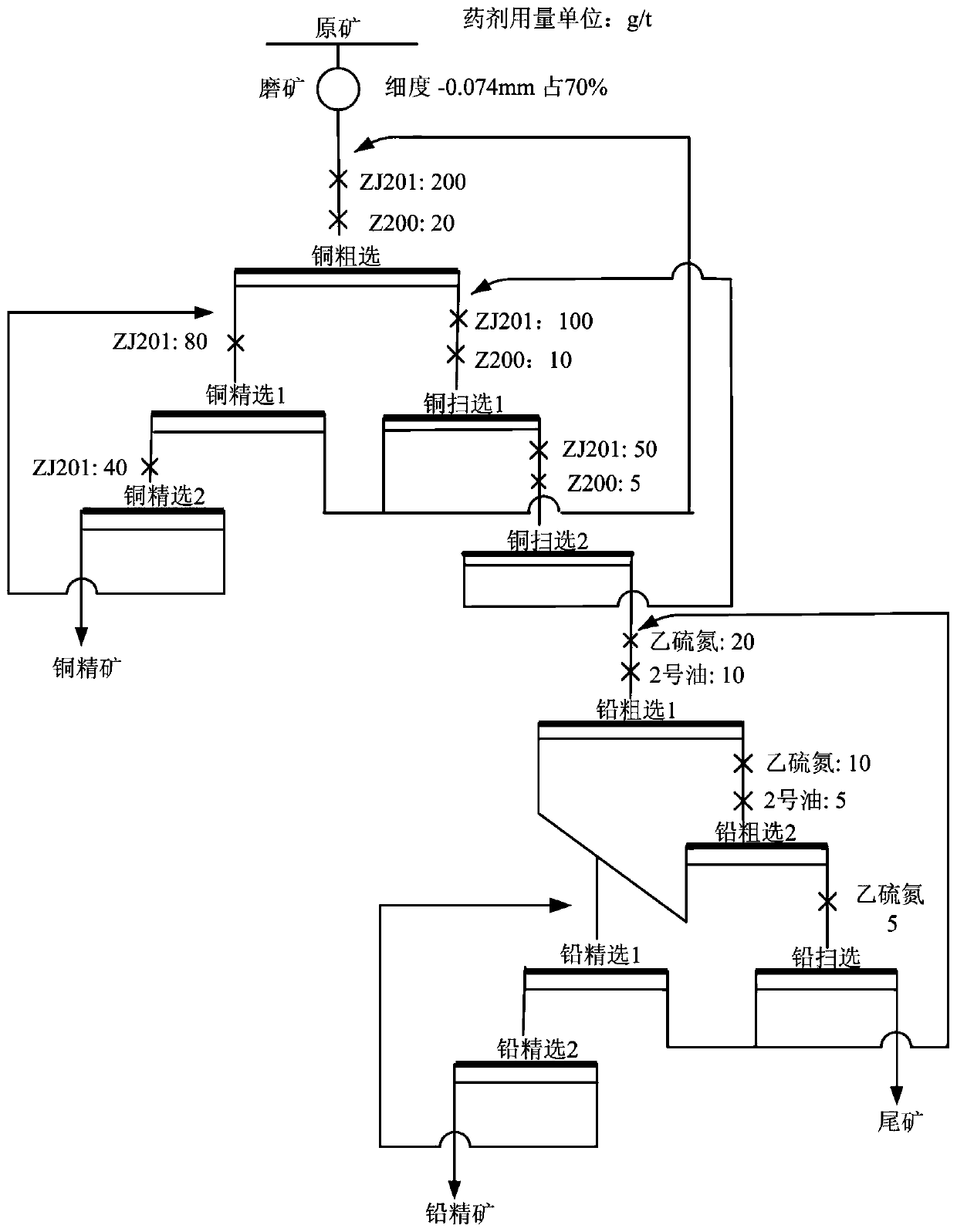

Differential flotation method for copper lead sulfide minerals

A technology for preferential flotation and sulfide ore, applied in flotation, solid separation, etc., can solve the problems of copper-lead mixed concentrate drug removal difficulties, dichromate environmental pollution, copper-lead separation difficulty, etc., and achieve low cost , The preparation method is simple, and the effect of adding safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The amount of pyrite slag (containing 1% copper) is 20t / h. Use the returned leaching solution to adjust the slurry, add a certain amount of sulfuric acid (the waste acid produced by flue gas washing can be used) and water, and control the concentration of the slurry to 40 %, control sulfuric acid concentration 40g / L, leaching at about 80°C for 4h, copper leaching rate is 60%. The amount of leachate is about 30m 3 / h, the concentration of sulfuric acid is about 32g / L. 13m out of the way 3 / h leachate, use washing liquid and raffinate to dilute to sulfuric acid concentration 8g / L, then remove suspended matter, enter copper extraction-electrowinning process. The remaining leachate is returned as pyrite slag slurry. The extraction agent consumption is 2.81kg / t-Cu.

Embodiment 2

[0039] The amount of pyrite slag (containing 1% copper) is 20t / h. Use the returned leaching solution to adjust the slurry, add a certain amount of sulfuric acid (the waste acid produced by flue gas washing can be used) and water, and control the concentration of the slurry to 40 %, control sulfuric acid concentration 50g / L, leaching at about 80°C for 4h, copper leaching rate is 65%. The amount of leachate is about 30m 3 / h, the concentration of sulfuric acid is about 40g / L. 8m out of the way 3 / h leachate, use washing liquid and raffinate to dilute to sulfuric acid concentration 8g / L, then remove suspended matter, enter copper extraction-electrowinning process. The remaining leachate is returned as pyrite slag slurry. The extraction agent consumption is 2.89kg / t-Cu.

Embodiment 3

[0041] The amount of pyrite slag (containing 1% copper) is 20t / h. Use the returned leaching solution to adjust the slurry, add a certain amount of sulfuric acid (the waste acid produced by flue gas washing can be used) and water, and control the concentration of the slurry to 40 %, control sulfuric acid concentration 60g / L, leaching at about 80°C for 4h, copper leaching rate is 68%. The amount of leachate is about 30m 3 / h, the concentration of sulfuric acid is about 48g / L. 6m out of the way 3 / h leaching liquid, use washing liquid and raffinate to dilute to sulfuric acid concentration 7.20g / L, then remove suspended matter, enter copper extraction-electrowinning process. The remaining leachate is returned as pyrite slag slurry. The extraction agent consumption is 3.05kg / t-Cu.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com