Method for extracting white carbon black from shale vanadium extraction tailing residue

A technology for extracting vanadium tailings and white carbon black, applied in chemical instruments and methods, silica, inorganic chemistry, etc., can solve the problems of long production time, low leaching rate and difficult leaching of silica products, and achieve improved The effect of leaching rate, widening the source of raw materials, and solving stockpiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

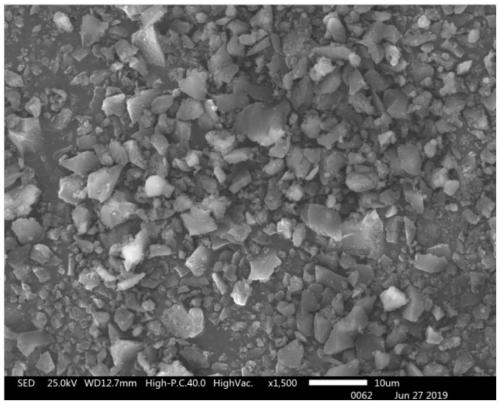

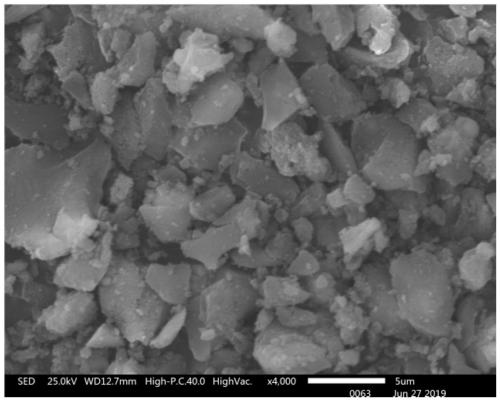

[0020] A method for extracting white carbon black from shale vanadium extraction tailings, said method comprising the steps of:

[0021] Step 1. Mix the vanadium extraction tailings with solid alkali and water to obtain a slurry. The mass ratio of the solid alkali to the vanadium extraction tailings is 1.5:1, and the solid-liquid ratio is 1:6;

[0022] Step 2. Raise the temperature of the slurry obtained in step 1 to 160° C., and control the reaction time to 120 minutes;

[0023] Step 3, after the reaction is completed, filter to obtain the filtrate and filter residue, adjust the pH value of the filtrate to 8, and obtain the silica gel;

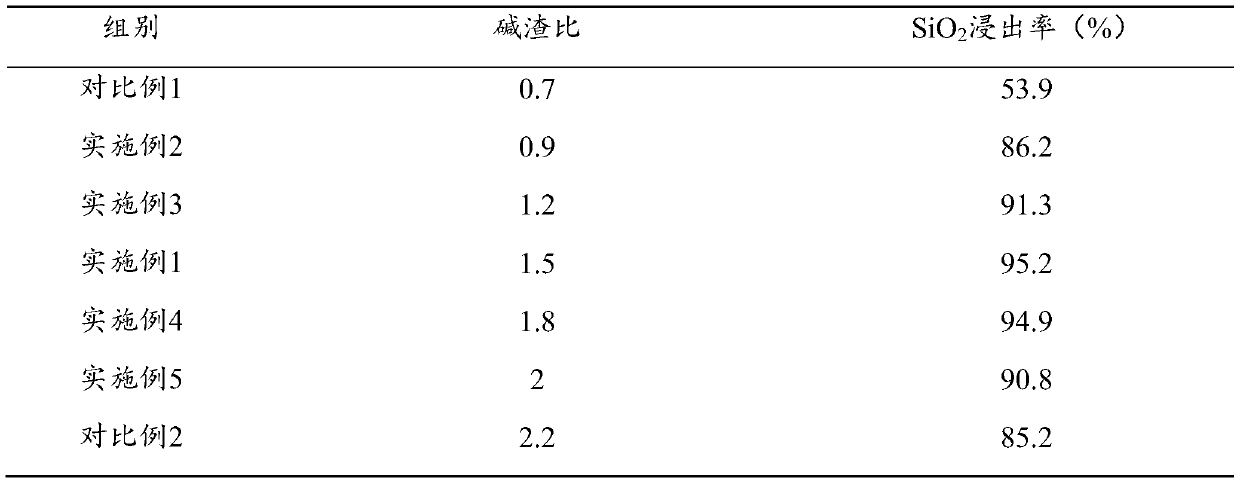

[0024] Step 4, drying and grinding the silica gel obtained in step 3 to obtain white carbon black. The silica leaching rate can reach as high as 95.2%, and the specific surface area reaches 105m 2 / g. Detection of SiO in products 2 The content reaches more than 92.8%, and the main content of the product meets the requirements of the HG / T3...

Embodiment 2- Embodiment 5

[0026] The mass ratios of the solid alkali to the vanadium extraction tailings described in the examples 2-5 are 0.9:1, 1.2:1, 1.8:1, 2:1 respectively, and the other conditions are the same as in the example 1.

Embodiment 6- Embodiment 8

[0028] The solid-to-liquid ratios described in Example 6-Example 8 are 1:4, 1:8, and 1:10 respectively, and other conditions are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com