A kind of lignin composite magnetic thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and lignin technology, which is applied in the field of preparation of functional materials, can solve the problems of poor toughness of elastomers, large intermolecular force, and difficulty in magnetic particles, and achieve improved magnetic properties, excellent mechanical properties, and weakened agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

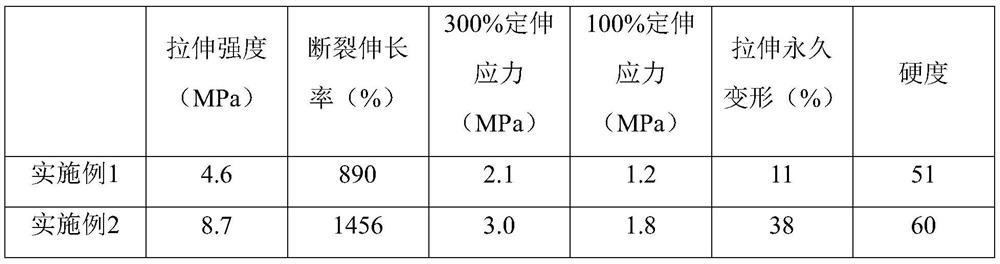

[0033] Example 1: A lignin-composite magnetic thermoplastic elastomer and its preparation method:

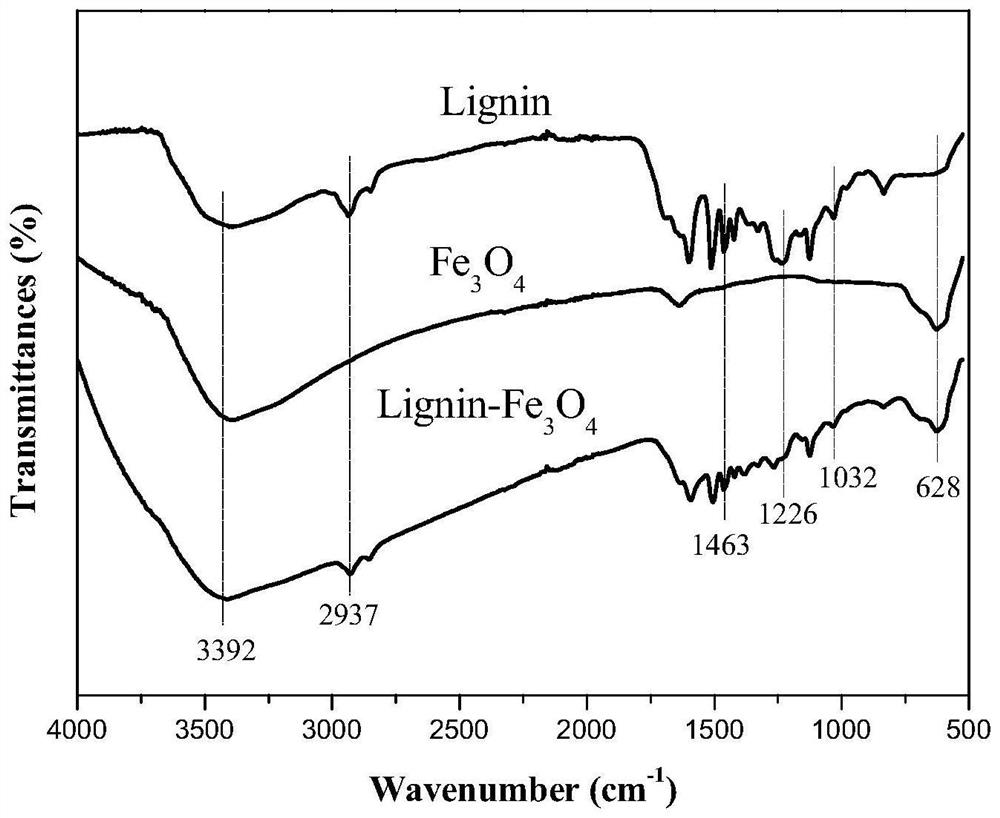

[0034] (1) Dissolve 110 g of lignin in 500 mL of tetrahydrofuran solvent, ultrasonicate at 40 KHz for 10 min, and filter to remove undissolved lignin to obtain a filtrate;

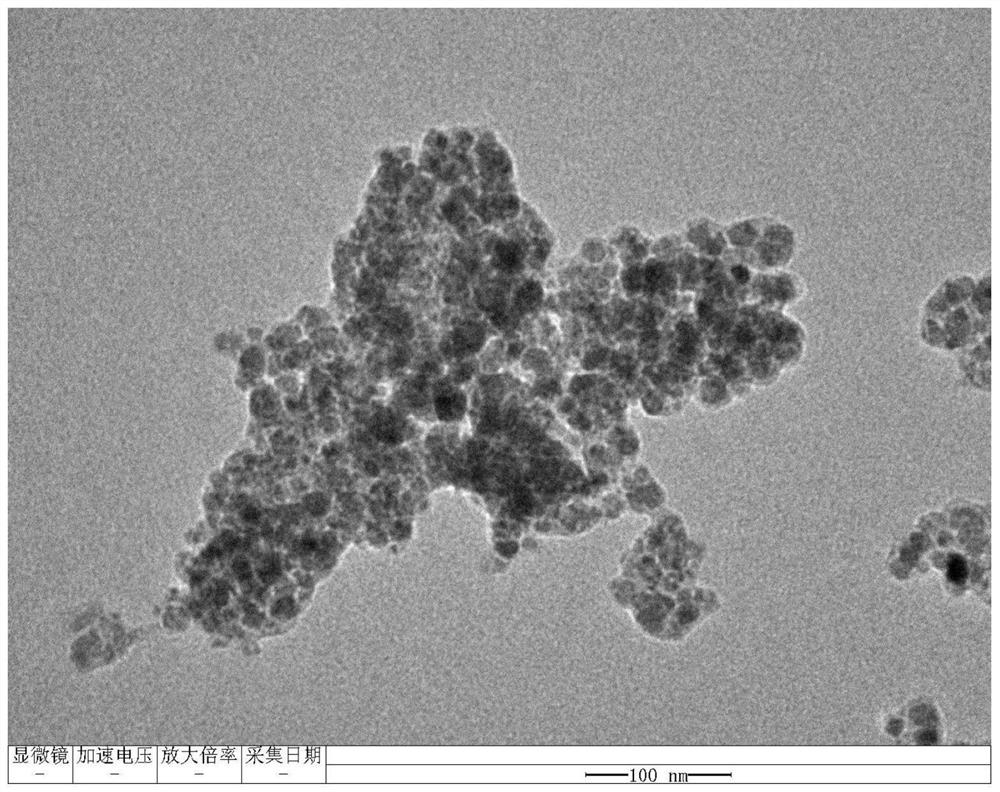

[0035] (2) 260g FeCl 3 ·6H 2 O and 96g FeCl 2 4H 2 O was dissolved in 12L of water, heated to 65°C, stirred for 10 min under nitrogen protection, and 25% wt concentrated ammonia water was added dropwise at a rate of 10 mL / min until black flocs appeared, and the pH was maintained above 10, and continued to stir for 2 h; The speed is 500rpm;

[0036] (3) When the temperature of the above reaction solution drops to 50°C, add the filtrate obtained in step (1) dropwise at a rate of 10mL / min, continue to stir at 500rpm / min for 30min, cool and age at room temperature for 1h, centrifuge at 4000rpmn for 10min, separate the product, and The solid was washed with water to neutrality to obtain lignin-ferric oxide n...

Embodiment 2

[0039] Example 2: A lignin-composite magnetic thermoplastic elastomer and its preparation method:

[0040] Step (1)~step (3) is the same as embodiment 1,

[0041] (4) Pre-masticate carboxylated nitrile rubber for 5 minutes at room temperature, then weigh 30 g of carboxylated nitrile rubber and place it in 300 mL of tetrahydrofuran solvent, dissolve overnight, and add the product obtained in step (3) with a solid content of 30 g, and mechanically stir at 500 rpm for 1 h , the resulting suspension was placed in a fume hood to evaporate the tetrahydrofuran solvent, and then placed in an oven to dry completely;

[0042](5) Add the material obtained in step (4) into an internal mixer, knead at 120°C for 30 minutes, and pass through the open mixer for 20 times to remove the sheet after discharging, put it in a flat vulcanizer and heat press at 180°C 30min molding.

Embodiment 3

[0043] Example 3: A lignin-composite magnetic thermoplastic elastomer and its preparation method:

[0044] Step (1)~step (3) is the same as embodiment 1,

[0045] (4) Pre-masticate carboxylated nitrile rubber for 5 minutes at room temperature, then weigh 20 g of carboxylated nitrile rubber and place it in 200 mL of tetrahydrofuran solvent, dissolve overnight, and add the product obtained in step (3) with a solid content of 40 g, and mechanically stir at 500 rpm for 1 h , the resulting suspension was placed in a fume hood to evaporate the tetrahydrofuran solvent, and then placed in an oven to dry completely;

[0046] (5) Add the material obtained in step (4) into an internal mixer, knead at 120°C for 30 minutes, and pass through the open mixer for 20 times to remove the sheet after discharging, put it in a flat vulcanizer and heat press at 180°C 30min molding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com