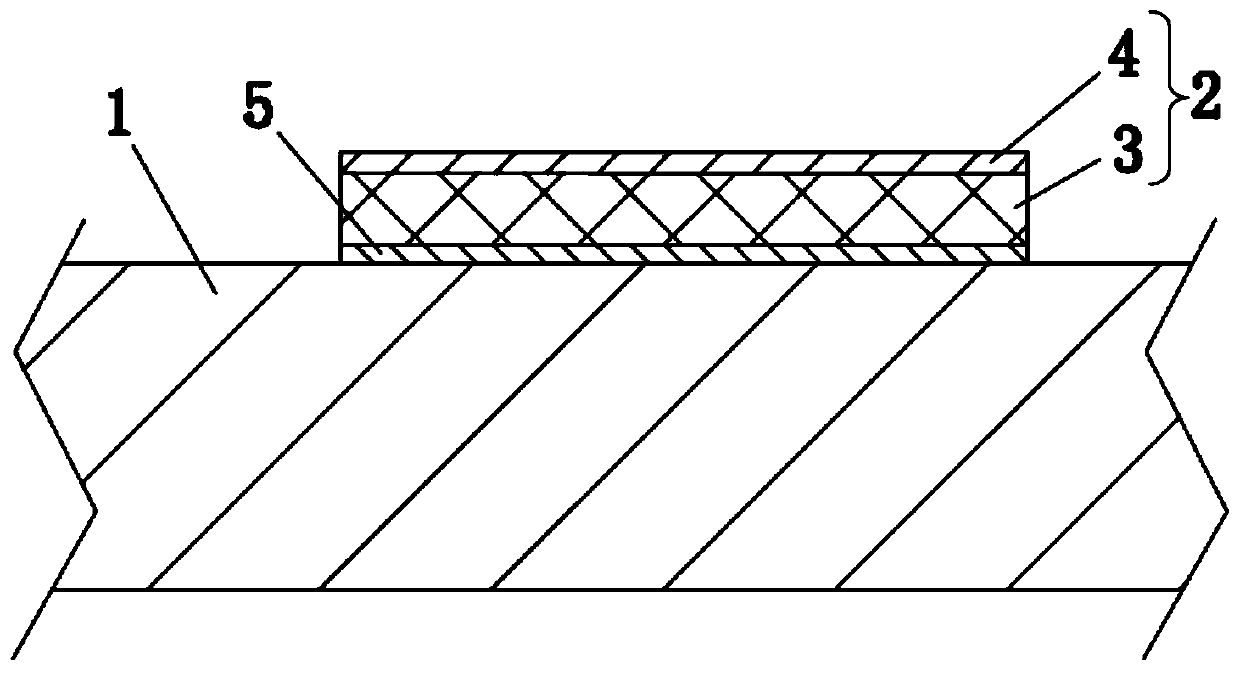

Electric conduction coating material, plating solution, and PCB circuit board and production method thereof

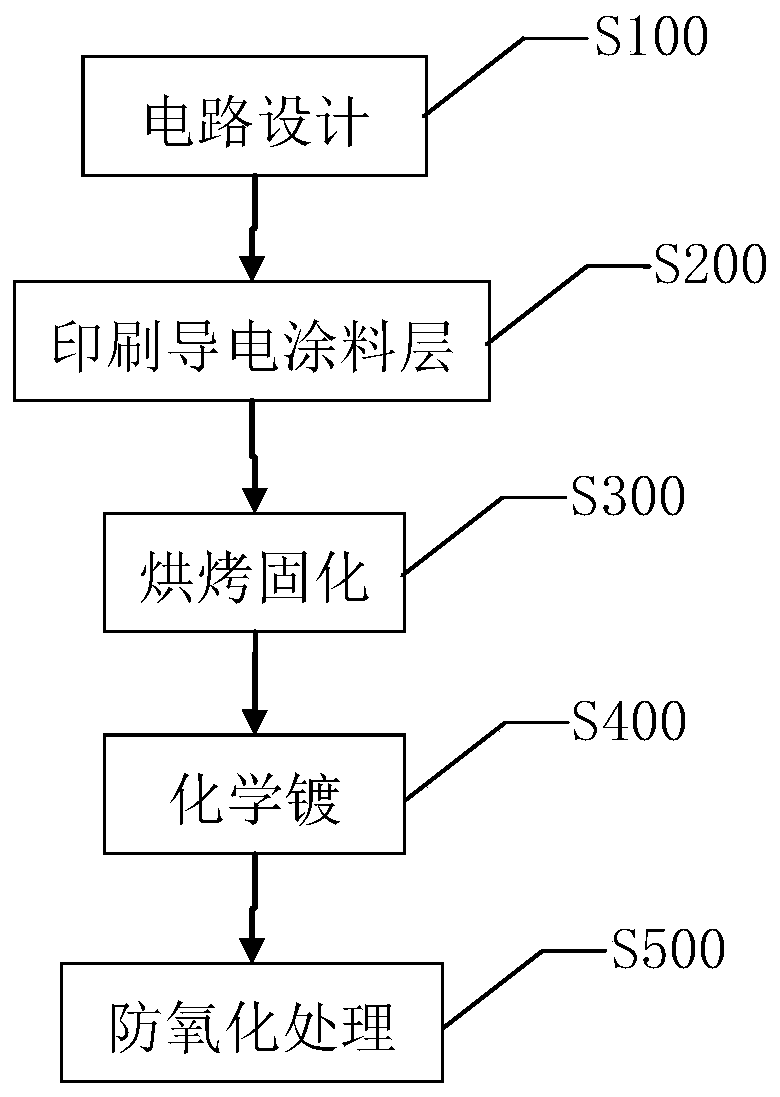

A technology of conductive paint and plating solution, applied in conductive paint, printed circuit manufacturing, printed circuit and other directions, can solve the problems of large investment in production equipment, high production technology requirements, and large plant area, to simplify the production process, shorten the The effect of production cycle and total cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0052]Preparation of conductive coating: first take by weight 20% of phenolic resin, 5% of dicyandiamide, 69% of conductive copper powder, 1% of divalent ester solvent, 3.5% of tetramethylbenzene solvent, polyacrylate block copolymer dispersed Agent 1%, silicone defoamer 0.1%, leveling agent 0.4%; then add the phenolic resin, divalent ester solvent, tetramethylbenzene solvent and polyacrylate block copolymer dispersant into the plastic tank Finally, use a disperser to stir and disperse for 2H at a speed of 1000rpm to fully mix the phenolic resin, divalent ester solvent, tetramethylbenzene solvent and polyacrylate block copolymer dispersant; then add dicyandiamide curing agent and Stir and disperse at a high speed for 10 minutes to fully mix the dicyandiamide curing agent with the uniformly mixed phenolic resin, divalent ester solvent, tetramethylbenzene solvent and polyacrylate block copolymer dispersant; finally add conductive copper powder, The leveling agent and defoamer we...

example 2

[0057] Preparation of conductive coating: first take by weight 15% of epoxy resin, 5% of dicyandiamide, 75% of conductive copper powder, 1% of divalent ester solvent, 2.5% of tetramethylbenzene solvent, polyacrylate block copolymer Dispersant 1%, organosilicon defoamer 0.1% and leveling agent 0.4%; Then the phenolic resin, divalent ester solvent, tetramethylbenzene solvent and polyacrylate block copolymer dispersant will be weighed and added to the plastic tank After inside, use a disperser to stir and disperse for 2 hours at a speed of 1000rpm to fully mix the phenolic resin, divalent ester solvent, tetramethylbenzene solvent and polyacrylate block copolymer dispersant; then add dicyandiamide curing agent and Stir and disperse at a speed of 800rpm for 10 minutes to fully mix the dicyandiamide curing agent with the uniformly mixed phenolic resin, divalent ester solvent, tetramethylbenzene solvent and polyacrylate block copolymer dispersant; finally add conductive copper powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com