One-component moisture-curing silicone graffiti-resistant smart coating and preparation method thereof

A moisture-curing, silicone technology, applied in coatings and other directions, can solve the problems of unsustainable anti-graffiti coatings and incomplete protection, achieve strong water and oil repellency, solve easy brittle cracking, and good flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

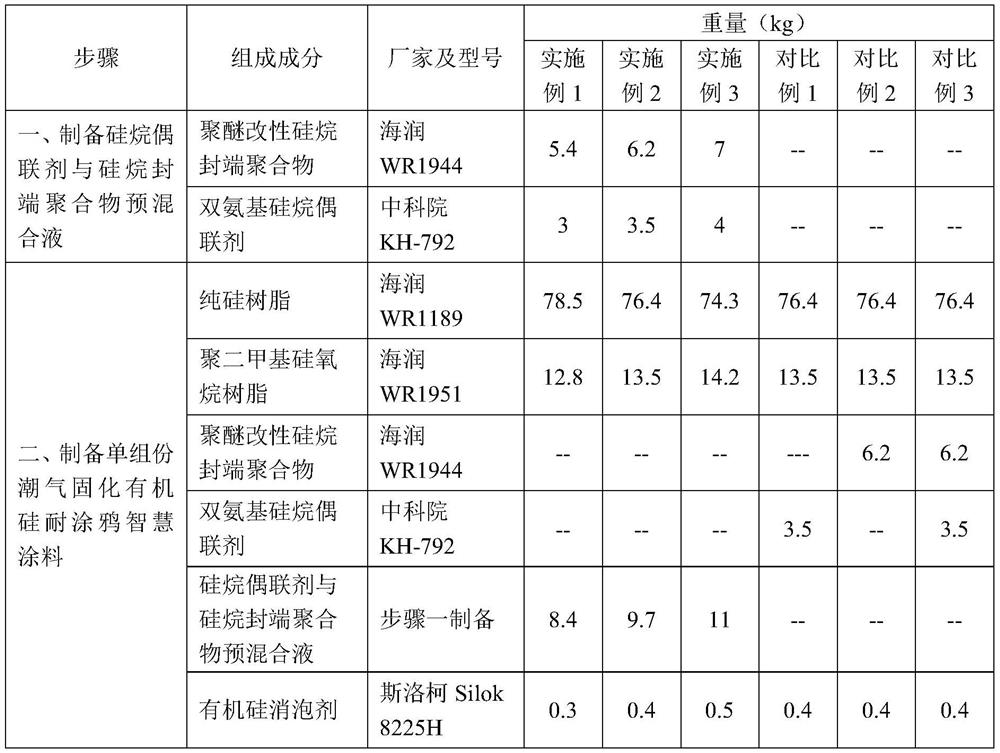

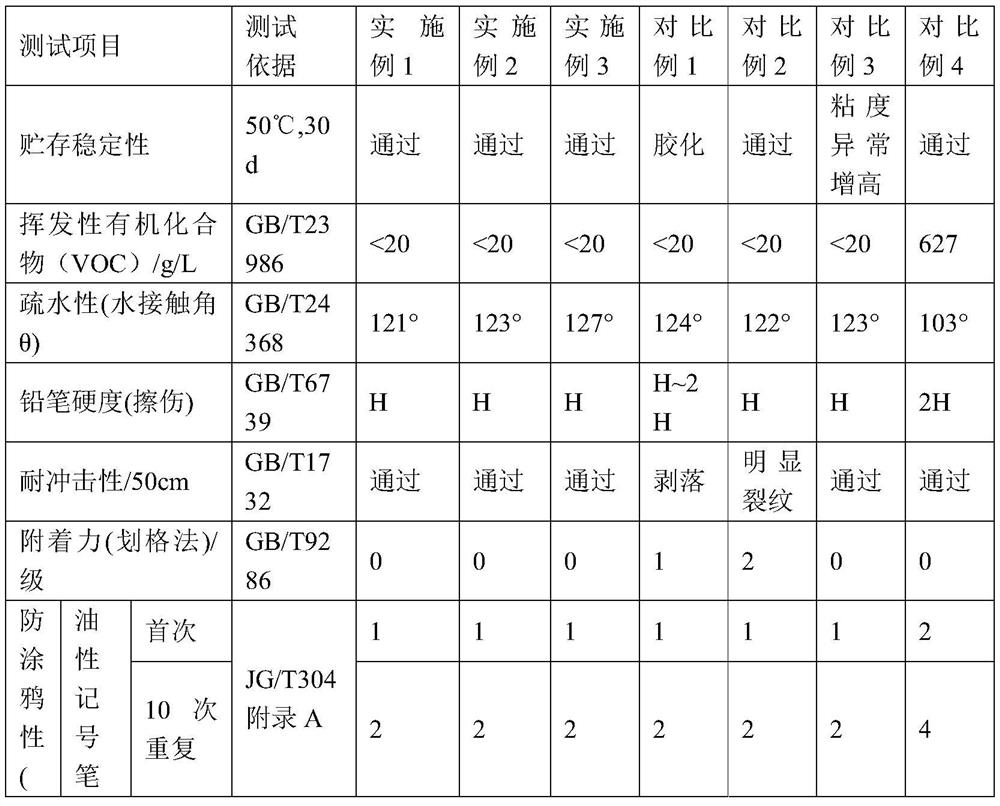

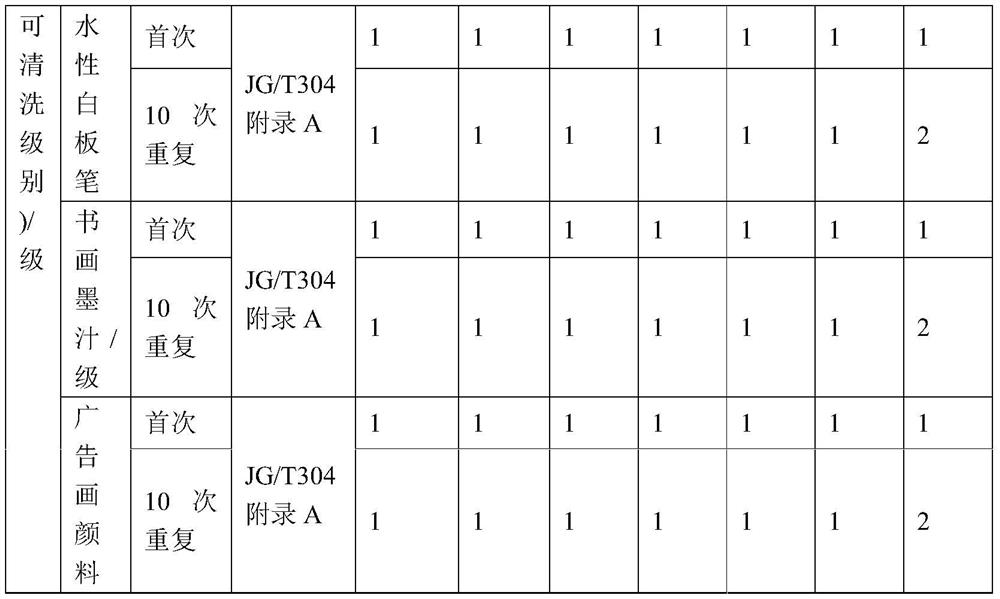

Embodiment 1

[0024] The preparation method of the one-component moisture-cured silicone graffiti-resistant smart coating of the present invention is as follows:

[0025] step one:

[0026] Add 5.4kg of polyether-modified silane-terminated polymer WR1944 from Hairun Company and 3.0kg of bisaminosilane coupling agent KH-792 from the Chinese Academy of Sciences in a dry and clean paint mixing tank. Stir and mix at 500 rpm for 15 minutes, then seal the package and leave for 2 hours to prepare a premixed liquid of bisaminosilane coupling agent and polyether-modified silane-terminated polymer for use in Step 2.

[0027] Step two:

[0028] Add 78.5kg of pure silicone resin WR1189 from Hairun Company, 12.8kg polydimethylsiloxane resin WR1951 from Hairun Company, and bisaminosilane prepared in step 1 in a dry and clean paint mixing tank. Coupling agent and polyether-modified silane-terminated polymer premix 8.4kg, Silok 8225H silicone defoamer 0.3kg, start stirring after adding, at 500-700 rpm Sti...

Embodiment 2

[0030] The preparation method of the one-component moisture-cured silicone graffiti-resistant smart coating of the present invention is as follows:

[0031] step one:

[0032] Add 6.2kg of polyether-modified silane-terminated polymer WR1944 from Hairun Company and 3.5kg of bisaminosilane coupling agent KH-792 from the Chinese Academy of Sciences into a dry and clean paint mixing tank. Stir and mix at 500 rpm for 15 minutes, then seal the package and leave for 2 hours to prepare a premixed liquid of bisaminosilane coupling agent and polyether-modified silane-terminated polymer for use in Step 2.

[0033] Step two:

[0034] Add 76.4kg of pure silicone resin WR1189 from Hairun Company, 13.5kg polydimethylsiloxane resin WR1951 from Hairun Company, and bisaminosilane prepared in Step 1 into the dry and clean paint mixing tank. Coupling agent and polyether-modified silane-terminated polymer premix 9.7kg, Silok 8225H silicone defoamer 0.4kg, start stirring after adding, at 500 ~ 70...

Embodiment 3

[0036] The preparation method of the one-component moisture-cured silicone graffiti-resistant smart coating of the present invention is as follows:

[0037] step one:

[0038] Add 7.0kg of polyether-modified silane-terminated polymer WR1944 from Hairun Company and 4.0kg of bisaminosilane coupling agent KH-792 from the Chinese Academy of Sciences into a dry and clean paint tank. Stir and mix at 500 rpm for 15 minutes, then seal the package and leave for 2 hours to prepare a premixed liquid of bisaminosilane coupling agent and polyether-modified silane-terminated polymer for use in Step 2.

[0039] Step two:

[0040] Add 74.3kg of pure silicone resin WR1189 from Hairun Company, 14.2kg polydimethylsiloxane resin WR1951 from Hairun Company, and bisaminosilane prepared in step 1 in a dry and clean paint mixing tank. Coupling agent and polyether-modified silane-terminated polymer premix 11.0kg, Silok 8225H silicone defoamer 0.5kg, start stirring after adding, at 500-700 rpm Stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com