Method for preparing 1,5-pentanediamine by fermentation

A technology of pentamethylenediamine and fermentation tank, which is applied in the field of fermentation and can solve problems such as complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

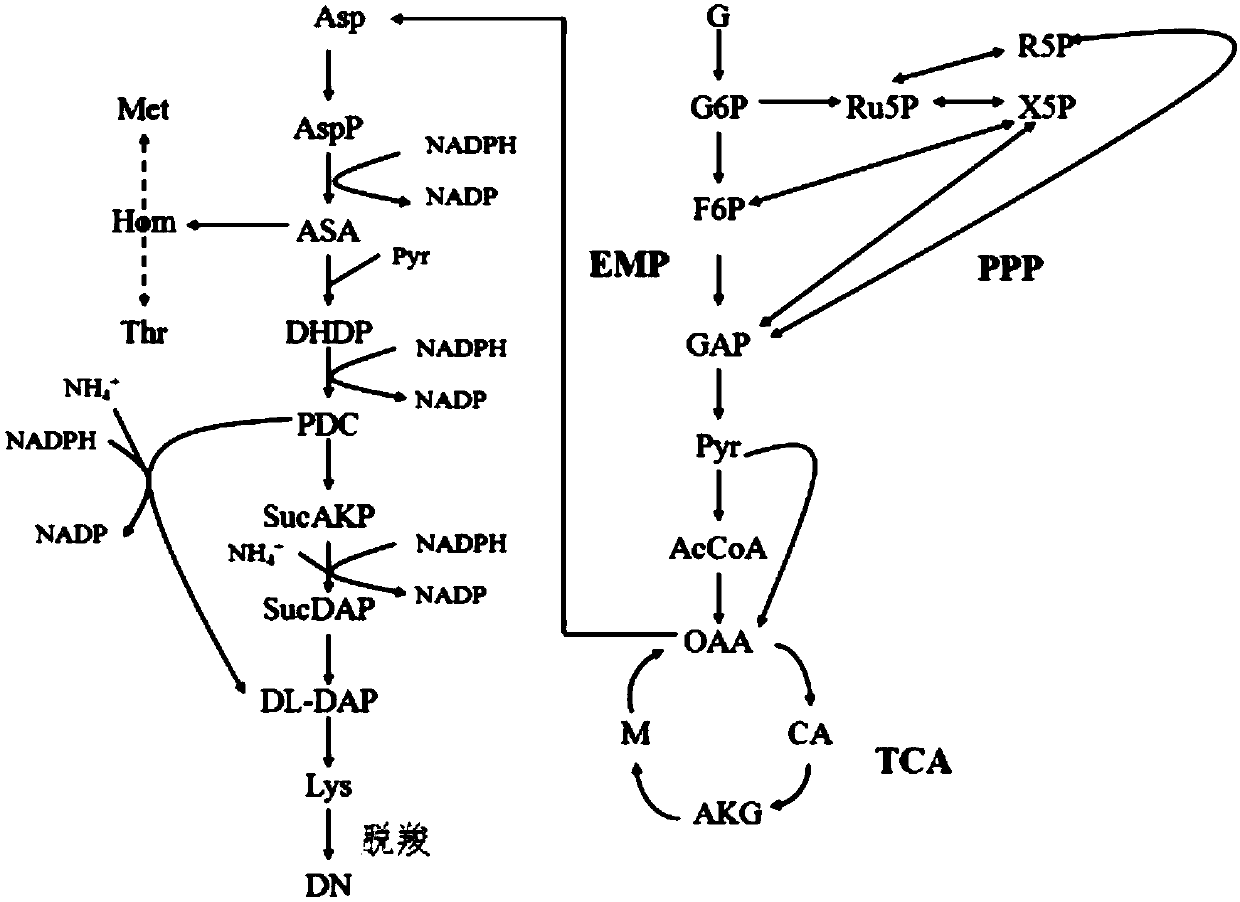

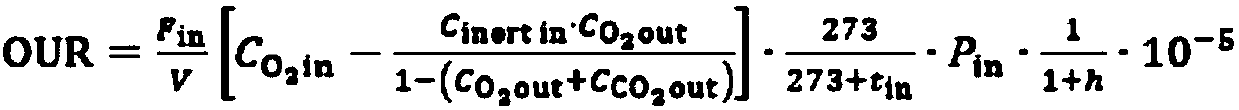

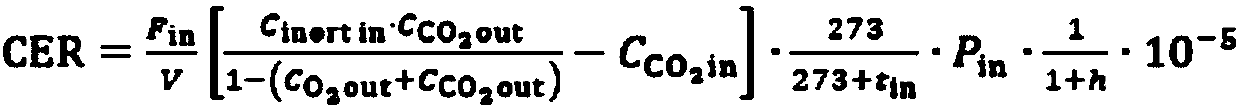

Method used

Image

Examples

Embodiment 1

[0068] Seed medium: KH 2 PO 4 0.2% (w / v, the following each embodiment, each medium component of comparative example is the same; 0.2% is 2g / L), MgSO 4 ·7H 2 O 0.45%, MnSO 4 ·H 2 O 20ppm, ammonium sulfate 0.5%, glucose 10%, corn steep liquor 0.15% (total nitrogen content 2.5wt%, the same below), threonine 0.035%; fermentation medium: KH 2 PO 4 0.04%, MgSO 4 ·7H 2 O0.32%, MnSO 4 ·H 2 O 0.028%, ammonium sulfate 1.0%, glucose 3.0%, corn steep liquor 0.26%, threonine 0.017%; fermentation feed medium: glucose 60%, ammonium sulfate 20%, threonine 0.1%.

[0069] The seed tank cultivation method is: 10L fermenter (working volume 4L), inoculation ratio 0.5% (v / v, the following examples and comparative examples are the same), aeration ratio 0.4vvm, temperature 35°C, rotating speed 300rpm, tank pressure 0.05MPa , 25% (v / v) ammonia water control pH is 6.0, in bacterial concentration OD 562 After reaching 0.75 (diluted 25 times), it was connected to a fermenter.

[0070] The fe...

Embodiment 2

[0074] Seed medium: KH 2 PO 4 0.5%, MgSO 4 ·7H 2 O 0.15%, MnSO 4 ·H 2 O 10ppm, ammonium sulfate 2.5%, glucose 5%, corn steep liquor 0.30%, threonine 0.015%; fermentation medium: KH 2 PO 4 0.02%, MgSO 4 ·7H 2 O 0.50%, MnSO 4 ·H 2O 0.010%, ammonium sulfate 0.2%, glucose 1.0%, corn steep liquor 0.50%, threonine 0.010%; fermentation feed medium: glucose 50%, ammonium sulfate 60%, threonine 1.0%.

[0075] The seed tank culture method is: 10L fermenter (working volume 5L), inoculum ratio 1.2%, aeration ratio 0.8vvm, temperature 39°C, rotating speed 800rpm, tank pressure 0.15MPa, 28% (v / v) ammonia water control pH is 7.0, OD 562 After reaching 1.00 (diluted 25 times), it was connected to a fermenter.

[0076] The fermenter culture method is: 30L fermenter (working volume 15L), inoculum ratio 5%, aeration ratio 0.8vvm, temperature 39°C, rotating speed 800rpm, tank pressure 0.05MPa, 28% (v / v) ammonia water control pH is 7.0, Feed medium was added after 2 h of fermentatio...

Embodiment 3

[0081] Seed medium: KH 2 PO 4 0.35%, MgSO 4 ·7H 2 O 0.28%, MnSO 4 ·H 2 O 15ppm, ammonium sulfate 1.7%, glucose 15%, corn steep liquor 0.05%, threonine 0.045%; fermentation medium: KH 2 PO 4 0.06%, MgSO 4 ·7H 2 O 0.10%, MnSO 4 ·H 2 O 0.050%, ammonium sulfate 0.5%, glucose 6.0%, corn steep liquor 0.10%, threonine 0.030%; fermentation feed medium: glucose 80%, ammonium sulfate 40%, threonine 0.5%.

[0082] The seed tank cultivation method is: 10L fermenter (working volume 5L), inoculum ratio 0.8%, aeration ratio 0.6vvm, temperature 37°C, rotating speed 500rpm, tank pressure 0.10MPa, 26% (v / v) ammonia water control pH is 6.5, OD 562 After reaching 0.75, connect to the fermenter.

[0083] The fermenter culture method is: 5L fermenter (working volume 3L), inoculum ratio 12%, aeration ratio 0.4vvm, temperature 35°C, rotating speed 500rpm, tank pressure 0.2MPa, 26% (v / v) ammonia water control pH is 6.0, Feed medium was added after 6 h of fermentation. The control RQ in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com