A kind of 022cr19ni10 stainless steel flange for nuclear power plant and its manufacturing method

A manufacturing method and stainless steel technology, applied in the field of stainless steel forging, can solve problems such as coarse grains, achieve small grain size, excellent microstructure, and prevent grain growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

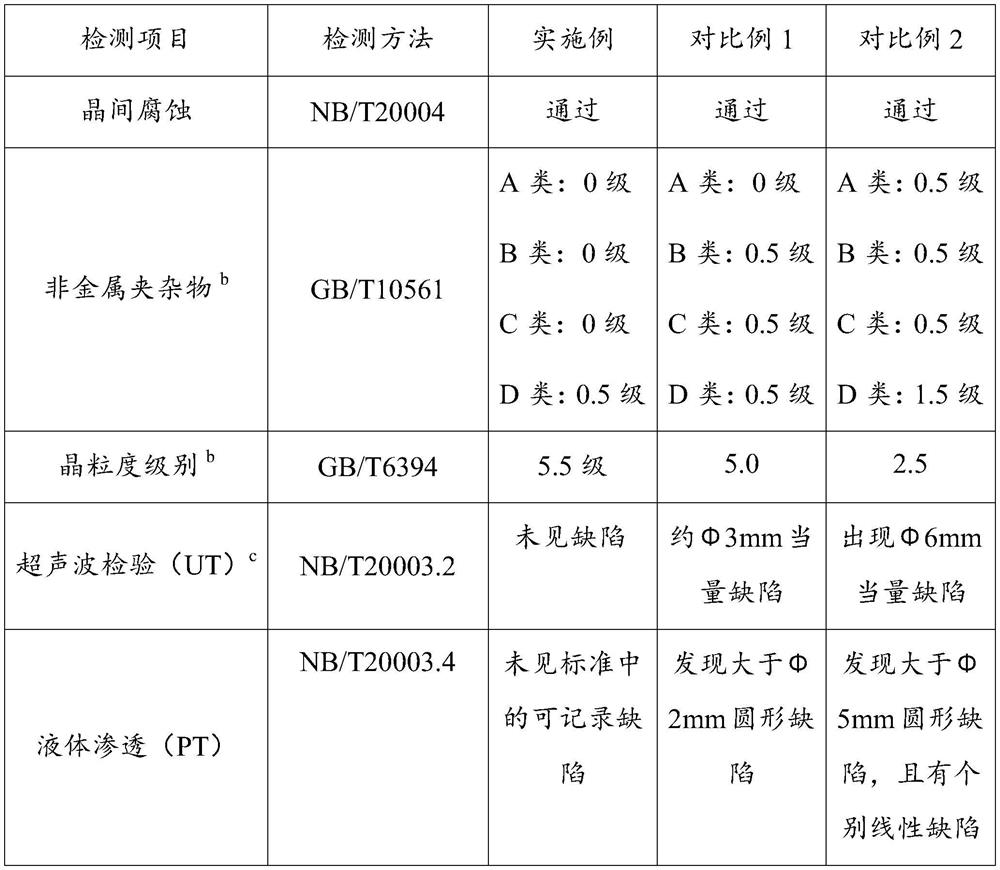

Examples

Embodiment

[0032] The chemical composition of stainless steel forgings is: C is 0.019%, Si is 0.43%, Mn is 1.72%, P is 0.013%, S is 0.001%, Cr is 19.26%, Ni is 10.65%, Cu is 0.8%, B is 0.001 %, the rest is iron.

[0033] The stainless steel forging is produced by the manufacturing method of the present invention: the raw material is refined into a stainless steel ingot containing the chemical composition in this embodiment by using an AOD furnace. The obtained stainless steel ingots are made into stainless steel forgings with a hydraulic press. The forging is formed through 3 fires, the forging ratios of the 3 fires are 2, 2, 1 respectively, and the heating temperatures of the 3 fires are 1200°C, 1180°C, 1180°C respectively. The riser end of the stainless steel ingot is removed by 18%, and the nozzle end of the stainless steel ingot is removed by 7%. The forged stainless steel forging is heated to 1100°C and held for 3 hours, and water is cooled by rapid circulation between a large poo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com