Milk product beverage with corn flavor and making method of beverage

A technology for dairy products and corn, applied in the direction of bacteria used in dairy products, other dairy products, food preparation, etc., can solve the problems of waste, not being able to achieve the desired dietary fiber well, and not being able to break corn seed coats, etc. Achieve good taste, inhibit the reproduction of harmful bacteria, and achieve good homogenization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

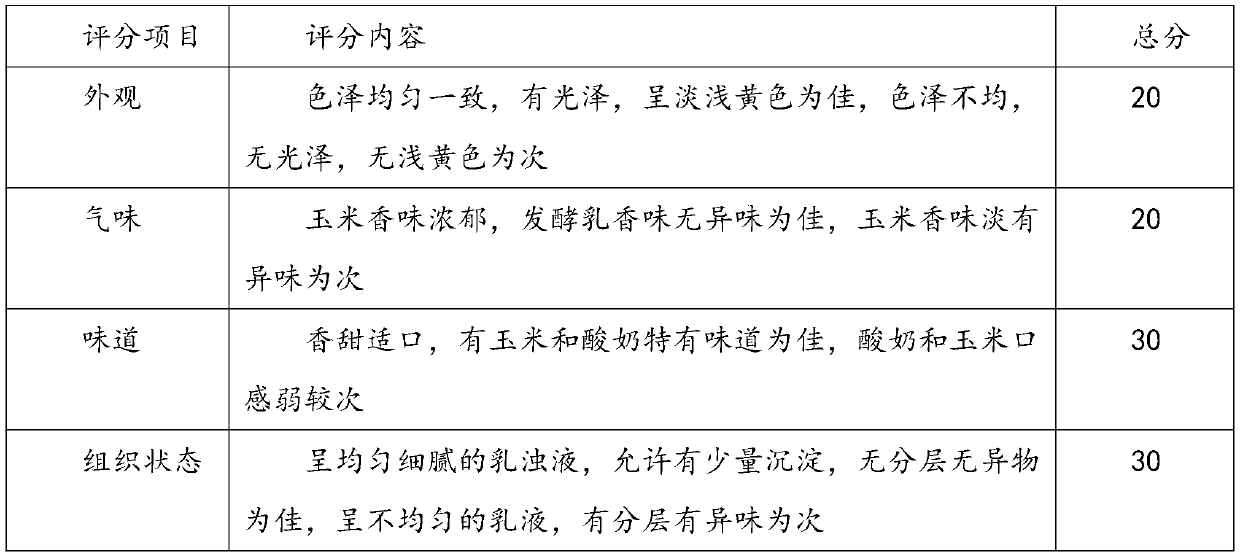

Examples

Embodiment 1

[0029] A method for preparing a corn-flavored dairy product, comprising the following steps:

[0030] (1) Preparation of corn serum: take 10 parts of fresh corn according to the weight components, and the corn is roasted before being crushed. The roasting temperature is 150° C., and the roasting time is 10 minutes. Soak for 1 hour, the water temperature is 30°C, and the baked corn is burnt yellow. After crushing the fresh corn into a slurry, add 1 part of calcium chloride and stir, and then add 6 parts of α-amylase with a concentration of 0.3%. Ensure that the temperature of the prepared corn milk is 87°C, and after stirring for 20 minutes, filter the corn milk with gauze to ensure that the temperature is 65°C, then add 8 parts of 0.12% glucoamylase, and stir for 1.5 hours to obtain corn milk ;

[0031] (2) Prepare milk: take 30 parts of pure milk and 18 parts of white sugar according to the weight components, add 0.1 part of Bacillus bulgaricus and place it in a thermostat. ...

Embodiment 2

[0037] A method for preparing a corn-flavored dairy product, comprising the following steps:

[0038] (1) Preparation of corn milk slurry: take 15 parts of fresh corn according to the weight components, and the corn is roasted before being crushed. The roasting temperature is 200 ° C, and the roasting time is 12 minutes. Soak for 1.5h, the water temperature is 30°C, and the baked corn is burnt yellow. After crushing the fresh corn into a slurry, add 1.5 parts of calcium chloride and stir, and then add 10 parts of α-amylase with a concentration of 0.3%. , ensure that the temperature of the prepared corn milk slurry is 87°C, and after stirring for 20 minutes, filter the corn milk slurry with gauze to ensure that the temperature is 65°C, then add 10 parts of 0.12% glucoamylase, and stir for 1.5 hours to obtain corn milk pulp;

[0039] (2) Prepare milk: take 35 parts of pure milk and 20 parts of white sugar according to the weight components, add 0.1 part of Bacillus bulgaricus a...

Embodiment 3

[0045] A method for preparing a corn-flavored dairy product, comprising the following steps:

[0046] (1) Preparation of corn serum: take 20 parts of fresh corn according to the weight components, and the corn is roasted before breaking, the roasting temperature is 260°C, the roasting time is 15min, and the roasted corn is water Soak for 2 hours, the water temperature is 30°C, and the baked corn is burnt yellow. After crushing the fresh corn into a slurry, add 2 parts of calcium chloride and stir, and then add 12 parts of α-amylase with a concentration of 0.3%. Ensure that the temperature of the prepared corn milk slurry is 87°C, and after stirring for 20 minutes, filter the corn milk slurry with gauze to ensure that the temperature is 65°C, then add 16 parts of 0.12% glucoamylase, and stir for 1.5 hours to obtain the corn milk slurry ;

[0047] (2) Prepare milk: take 40 parts of pure milk and 24 parts of white sugar according to the weight components, add 0.2 parts of lactic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com