Automatic drilling and pressing pin equipment for plunger pump swash plate

A plunger pump and swash plate technology, applied in the field of automatic drilling and pinning equipment, can solve the problems of heavy labor and low production efficiency, and achieve the effects of reducing labor, improving production efficiency, and reducing electrical complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

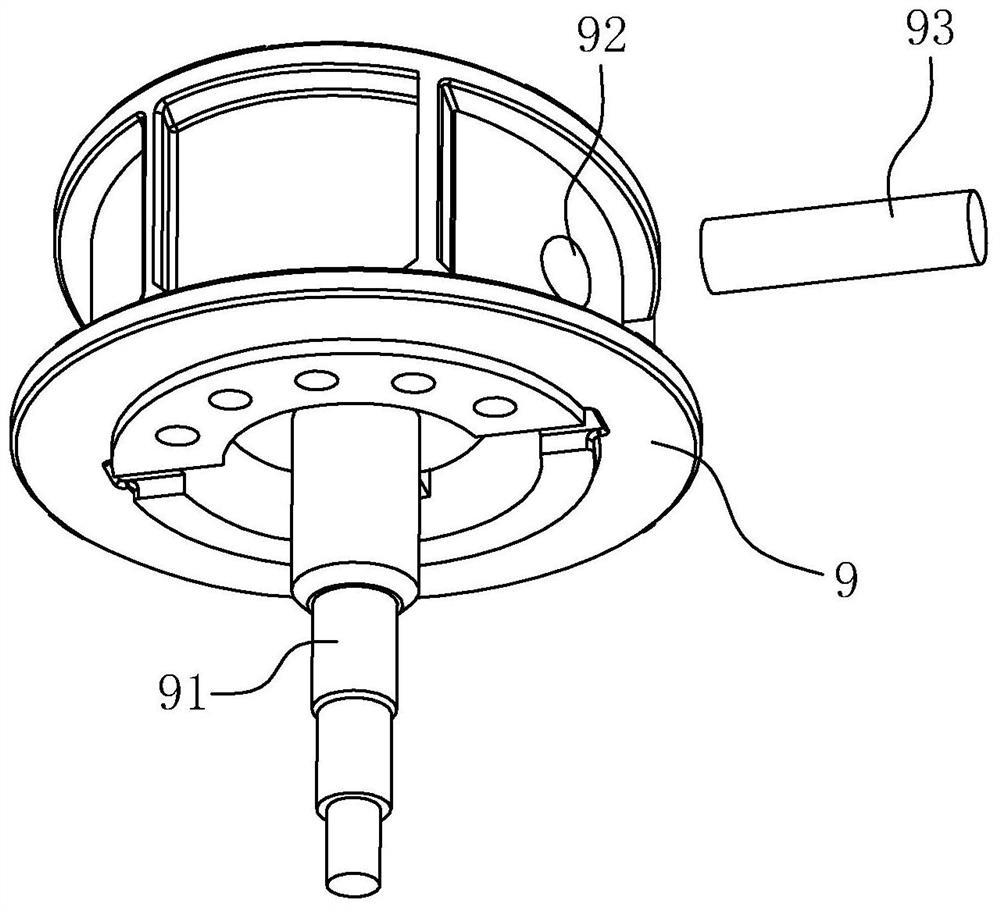

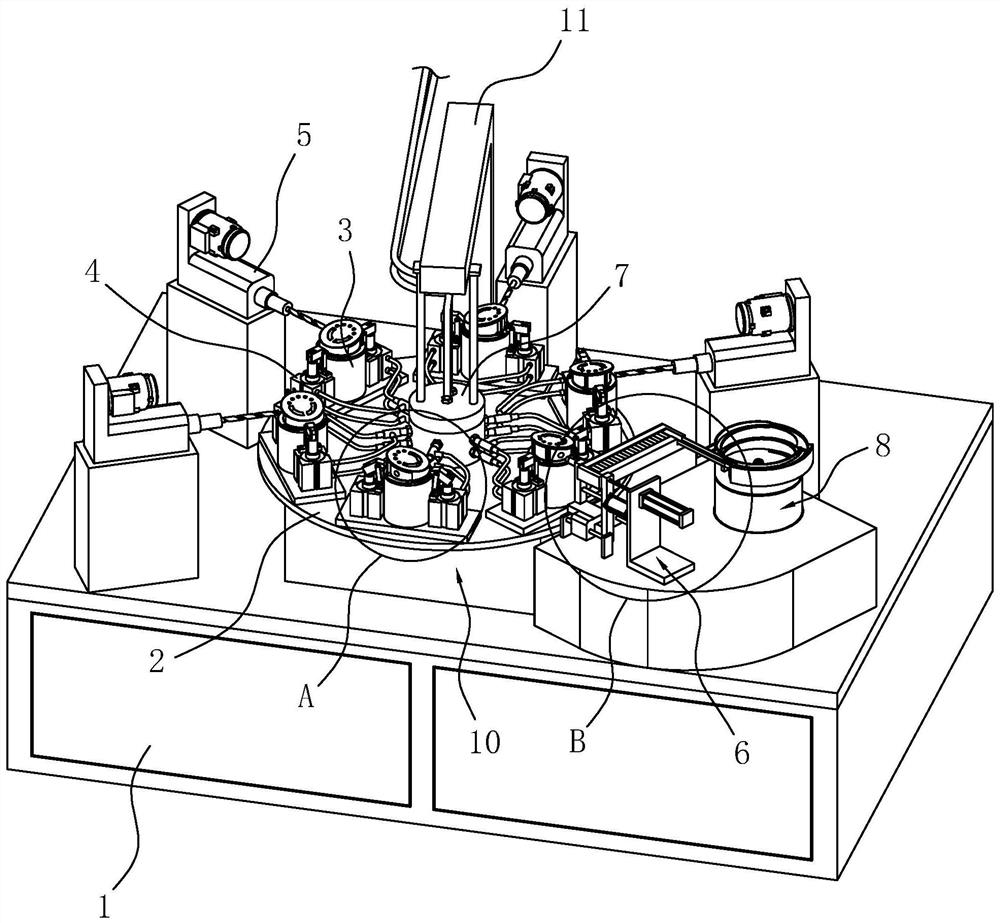

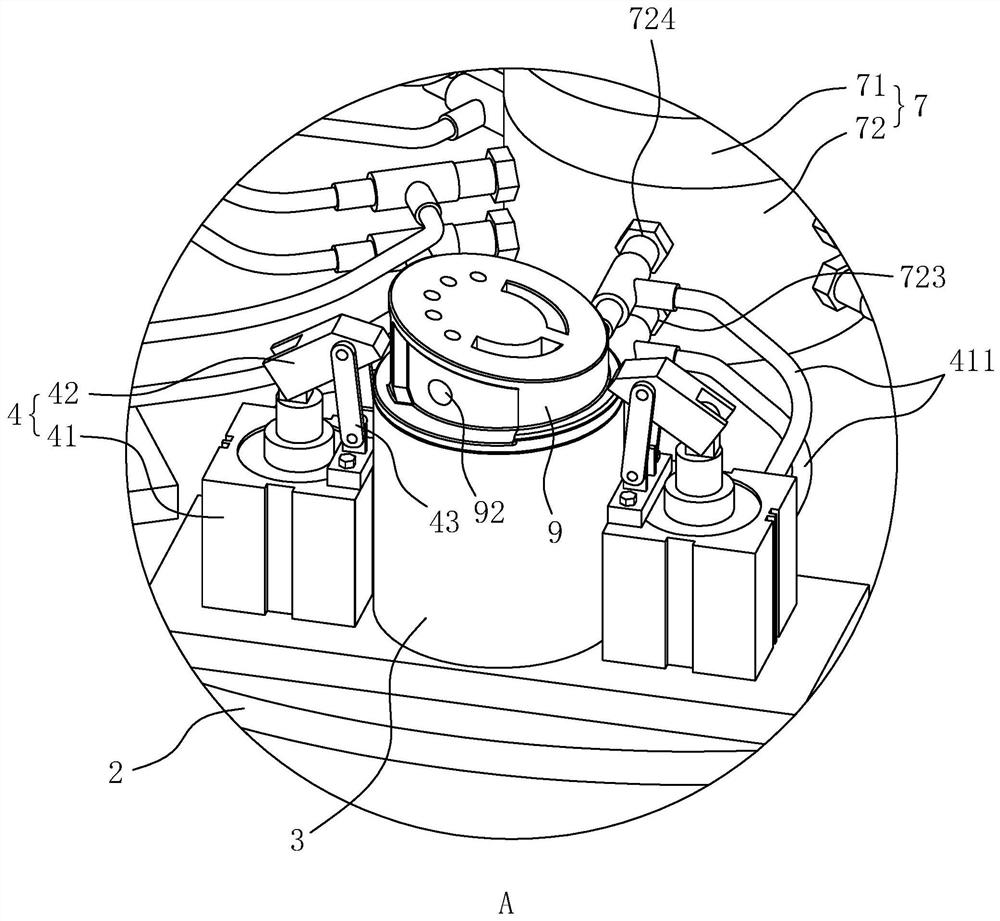

[0038] refer to figure 2 , is an automatic drilling and pinning device for a swash plate of a plunger pump disclosed in the present invention, comprising a frame 1, an indexing turntable 2 arranged on the top surface of the frame 1, and a plurality of Based on the clamping seats 3 for positioning the swash plate 9 and the clamps 4 for clamping the swash plate 9 , the clamping seats 3 are evenly distributed along the circumferential direction of the indexing turntable 2 . The top surface of the frame 1 outside the indexing turntable 2 is provided with a drilling rig 5 for drilling or reaming, a pinning machine 6 for pinning, and the circumferential distribution of the drilling rig 5 and pinning machine 6 on the indexing turntable 2 , Drilling machine 5, press pin machine 6 one by one are facing different holders 3, for processing the swash plate 9 on the holder 3. Frame 1 is provided with loading and unloading station 10, and there is clamp seat 3 correspondingly at 10 places...

Embodiment 2

[0049] An automatic drilling and pin pressing device for the swash plate 9 of a plunger pump, the difference between Embodiment 2 and Embodiment 1 is:

[0050] refer to Figure 7 , the top surface of the holder 3 is provided with a positioning projection 31 for being embedded in the hole on the end surface of the swash plate 9, the positioning projection 31 is slidably arranged in the holder 3 along the vertical direction, and the edge of the top surface of the positioning projection 31 is provided with an inverted horn. The piston rod of the clamping cylinder 41 is connected to the positioning projection 31 through a connecting rod 32 .

[0051] The height of the positioning bump 31 is set as follows: when the clamping cylinder 41 is in the shortened state, the height of the positioning bump 31 protruding from the top surface of the clamp seat 3 is 0.5~1.5mm, at this time, personnel can place the workpiece on the clamp seat 3 , The positioning bump 31 can play a preliminary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com