Distributed water feeding type multistage-AO series-connection efficient biological denitrification system and method

A technology for biological denitrification and water inflow, which is applied in the fields of water pollutants, sustainable biological treatment, chemical instruments and methods, etc., can solve the problems of high energy consumption for denitrification and low denitrification rate, and achieves low energy consumption and energy saving. Power and equipment, the effect of improving the total nitrogen removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

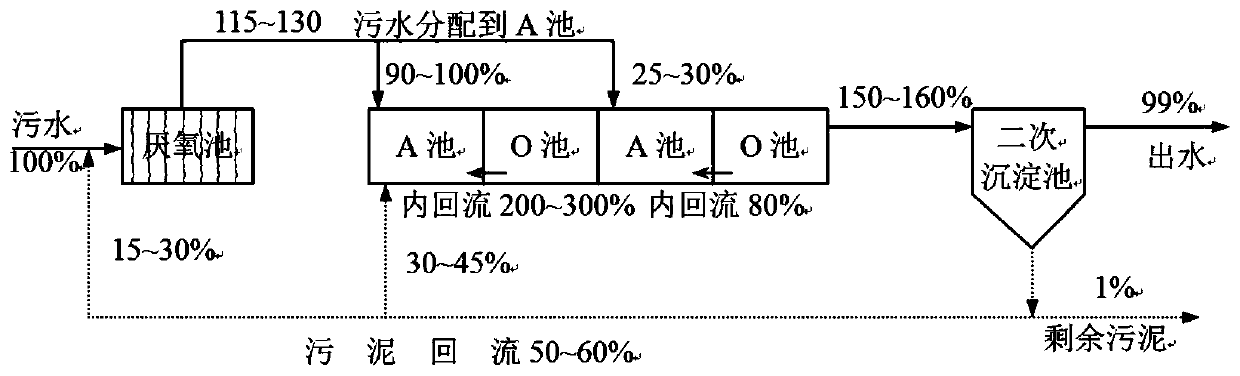

[0040] Embodiment 1 (two-stage AO series process)

[0041] This embodiment provides a process flow in the case of two-stage AO series connection, specifically including:

[0042] Raw sewage first enters the first-stage anoxic pool, which receives the returning sludge at the same time. The function of the first-stage anoxic pool is denitrification and denitrification. At the junction of this pond and the first-stage aerobic pond, an air-lift internal backflow measure is provided, and the nitrifying liquid of the first-stage aerobic pond is returned to the first-stage anoxic pond at a flow rate of about 300% (specifically, the backflow The ratio should be determined according to the water quality). The nitrate in the first-stage anoxic pool comes from the above-mentioned returning sludge and the returning nitrification liquid, and the organic matter in the first-stage anoxic pool comes from raw sewage, so denitrification and denitrification are mainly carried out in the first-s...

Embodiment 2

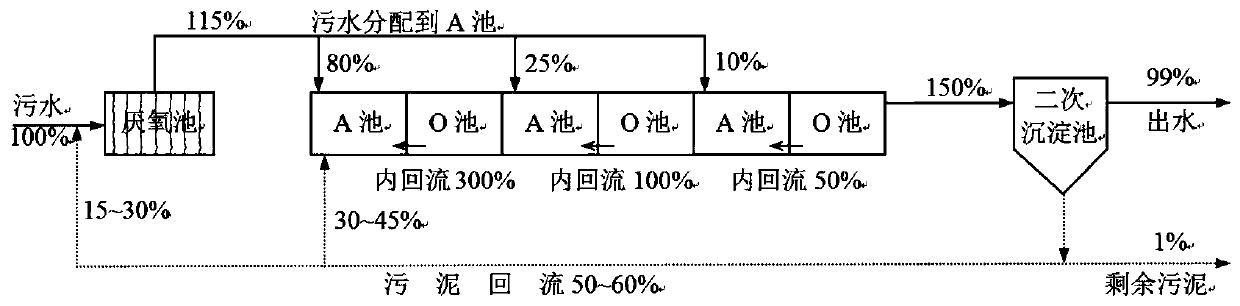

[0046] Embodiment 2 (three-stage AO series process)

[0047] Compared with the two-stage AO process in Example 1, the three-stage AO series process adds an anoxic pool and an aerobic pool. The first four reaction pools have the same functions, and the difference lies in the inflow of sewage flow.

[0048] After being treated in the second-stage aerobic pool, the sewage further enters the third-stage anoxic pool. For the same reason, the third level of anoxic needs to introduce a small amount of raw sewage to supplement the carbon source required for denitrification. On the premise of introducing raw sewage organic matter, the third-stage anoxic tank denitrifies and removes the nitrate from the second-stage aerobic tank and the returned nitrate.

[0049] The sewage further enters the third-level aerobic pool. In the third-level aerobic pool, the ammonia nitrogen (maybe Kjeldahl nitrogen) introduced into the sewage by the third-level anoxic pool is oxidized to nitrate, and fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com