Preparation method of covalent organic framework film

A technology of covalent organic framework and film, applied in the field of preparation of covalent organic framework film, can solve the problems of small size of sheet-like film, low peeling efficiency, etc., and achieves simple reaction device, low operating cost and good universality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

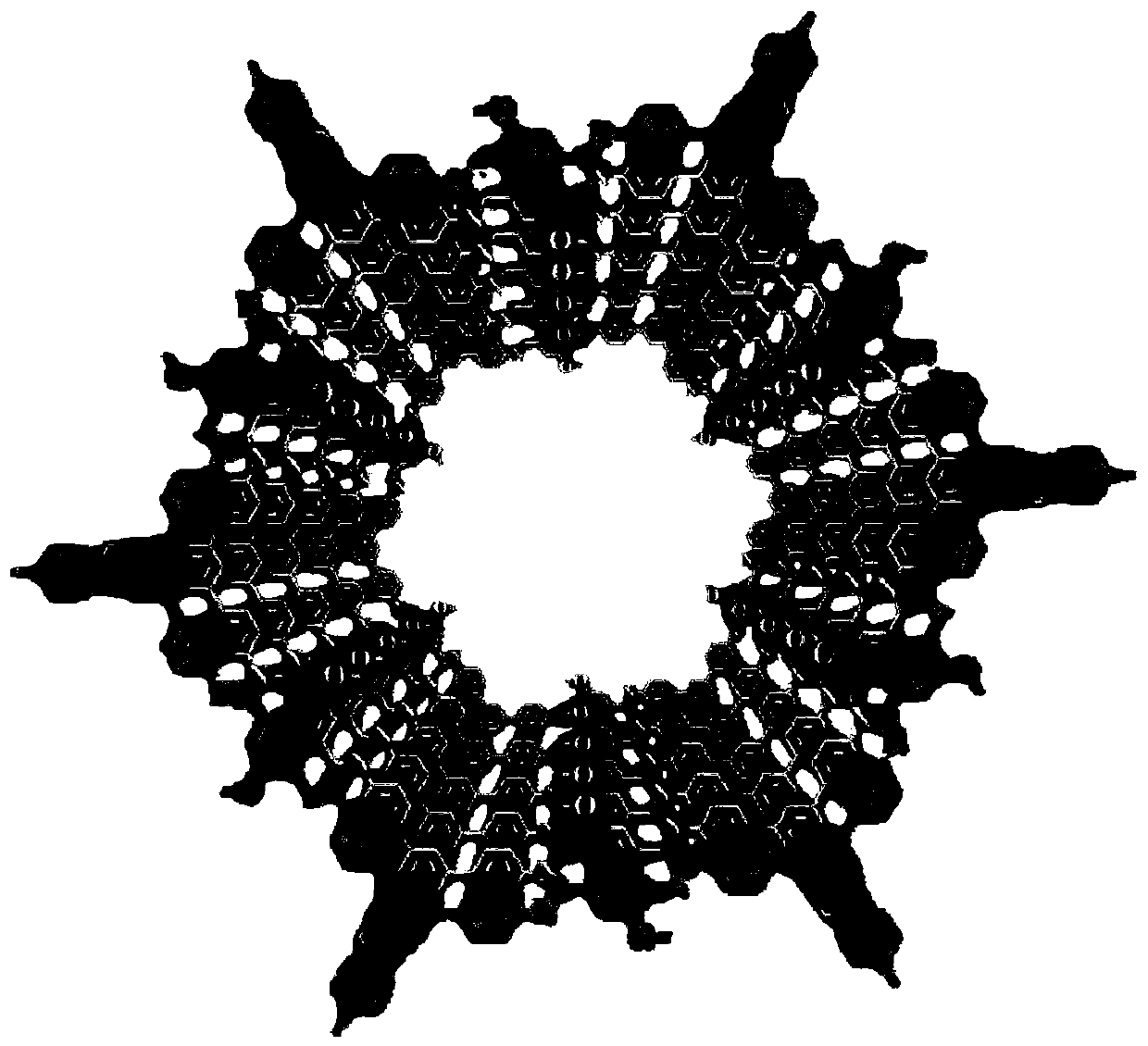

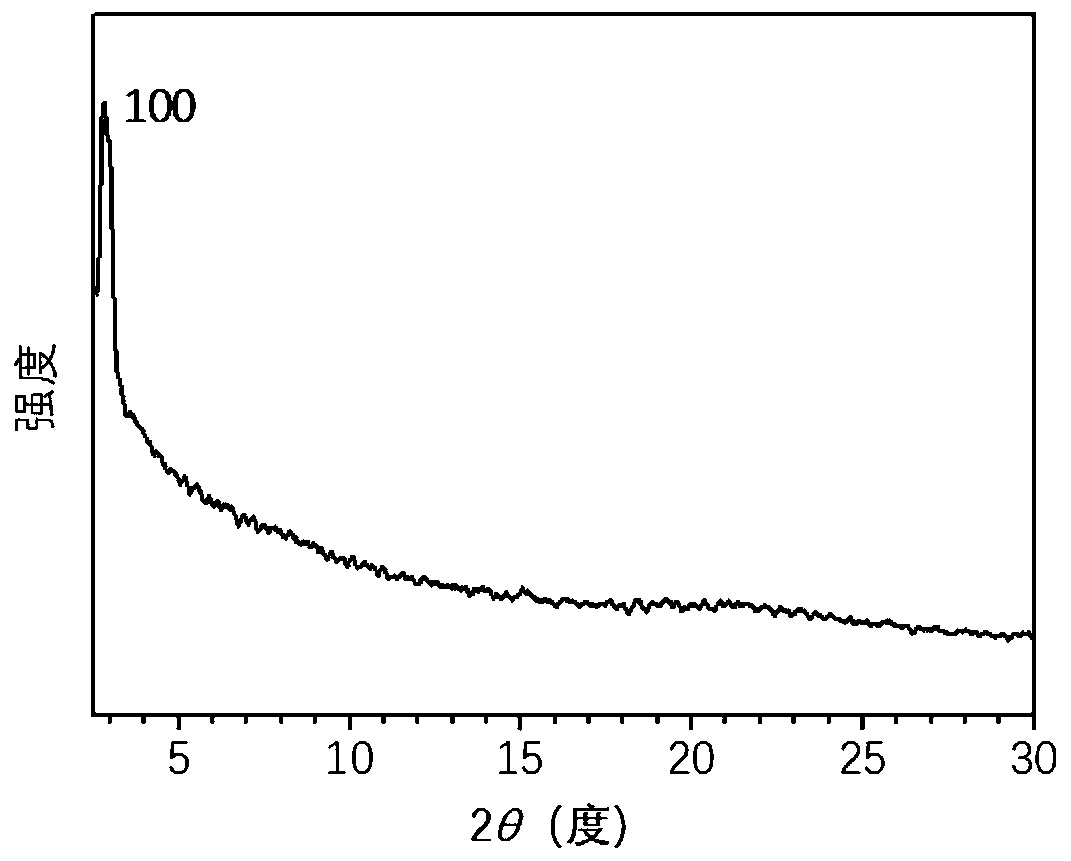

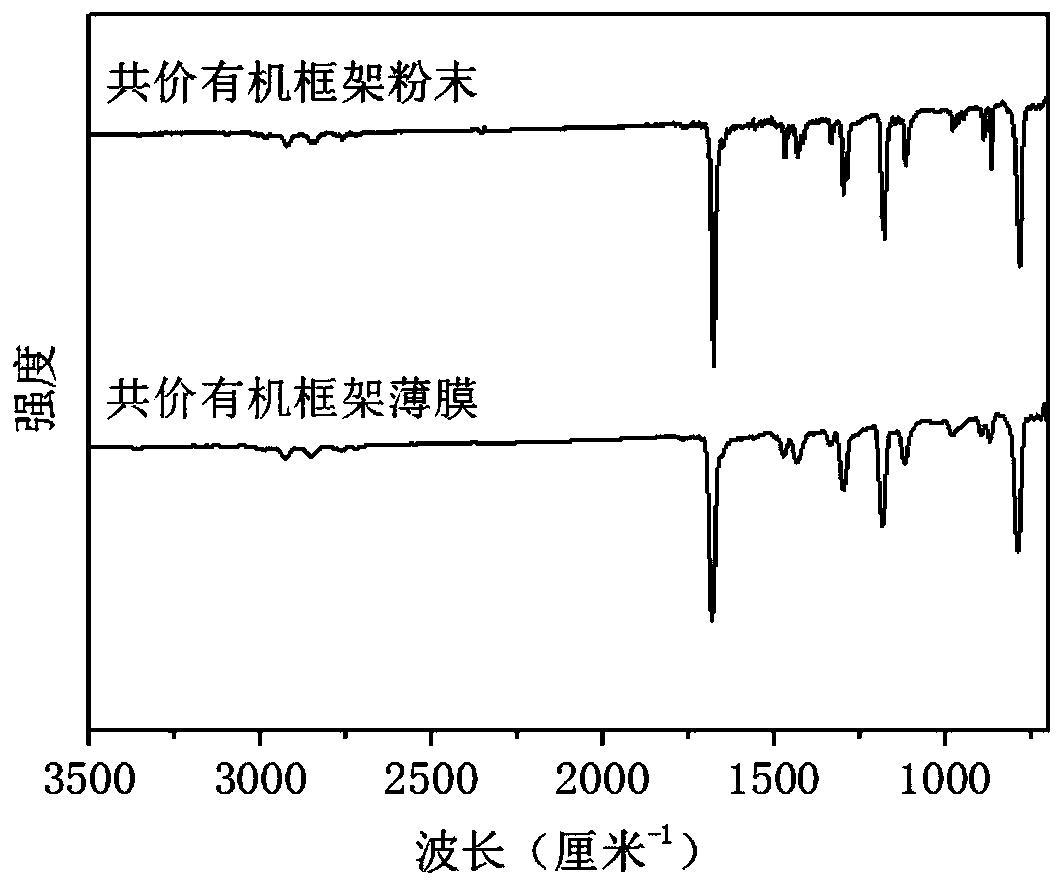

[0027] The covalent organic framework powder used in this example is synthesized by solvothermal method from 2,5-dimethoxyterephthalaldehyde and 1,3,5-tris(4-aminophenyl)benzene, figure 1 It is a schematic diagram of the covalent organic framework structure, and the rest of the raw materials are commercially available products.

[0028] Weigh 2 mg of covalent organic framework powder, wrap it tightly with filter paper and put it into a glass vial, add 2 ml of o-dichlorobenzene into the glass vial, put the substrate silicon wafer into it, add 6 moles per liter After adding 0.2 ml of acetic acid, put the glass vial into a hydrothermal reaction kettle, heat it to 120°C, and react for 4 hours, 6 hours, 8 hours, 12 hours or 24 hours. The longer the reaction time, the thickness of the obtained covalent organic framework film thicker. After the reaction, the hydrothermal reactor was allowed to stand at room temperature, and the substrate silicon wafer was taken out, soaked and clean...

Embodiment 2

[0033] A method for preparing a covalent organic framework film, the covalent organic framework is a covalent organic framework powder connected by imine bonds, the covalent organic framework powder is wrapped in filter paper, and the covalent organic framework powder is placed in a reaction solvent adjacent In the hydrothermal reaction kettle of dichlorobenzene, put the substrate silicon chip into the hydrothermal reaction kettle, add the catalyst acetic acid, seal the hydrothermal reaction kettle, heat the reaction at 60°C, and let it stand at room temperature after the reaction is completed. After taking out the substrate and cleaning it, a covalent organic framework film is obtained.

Embodiment 3

[0035] A method for preparing a covalent organic framework film, the covalent organic framework is a covalent organic framework powder connected by borate bonds, the covalent organic framework powder is wrapped in filter paper, and the covalent organic framework powder is placed in a reaction solvent In the hydrothermal reaction kettle of trimethylbenzene, put the substrate quartz into the hydrothermal reaction kettle, add the catalyst trifluoroacetic acid, seal the hydrothermal reaction kettle, heat the reaction at 80°C, and let it stand at room temperature after the reaction is completed. After taking out the substrate and cleaning it, a covalent organic framework film is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com