Concrete faced rockfill dam face plate disengaging and positioning detection method based on vibration sensing technology

A vibration sensing and positioning detection technology, applied in dams, barrages, measuring devices, etc., can solve the problems of large data dispersion, inability to fit equipment, and difficult operation, and achieve high reliability and large aspect ratio. , the detection effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

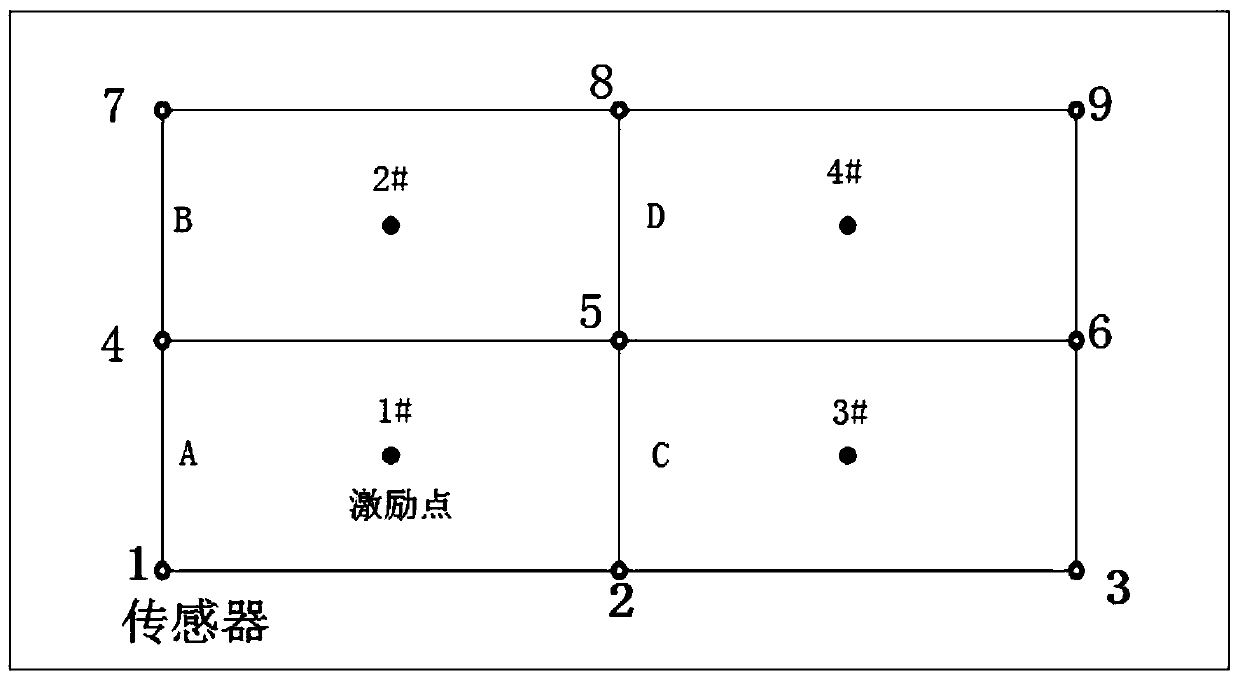

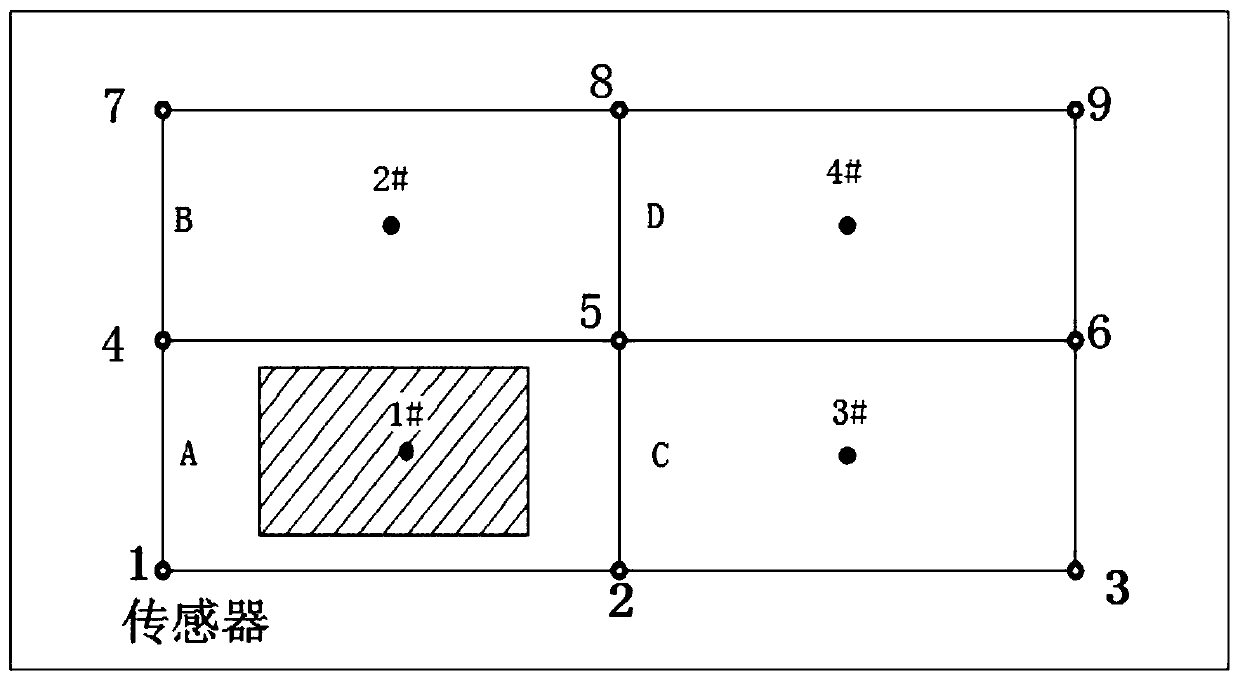

[0035] A panel void and positioning detection method based on vibration sensing technology, the steps are as follows:

[0036] (1) Step 1: Determine whether there is a gap in the lower part of the panel. The specific implementation method is:

[0037] ① According to the size of the panel, the angle of inclination and the material properties of the underlying soil, select a suitable acceleration sensor for panel detection. In this embodiment, the length of the concrete panel is 4m, the width is 2m, and the thickness is 0.15m. The modulus of elasticity of the panel is E=31GPa, Poisson's ratio ,density ; According to the numerical simulation analysis results, when there is no void at the bottom of the concrete slab, the first-order and second-order natural frequencies of the concrete slab are 61.2Hz and 64.9Hz, respectively. This also requires the acquisition frequency of the vibration sensor to be at least 350 Hz or higher, so medium and high frequency vibration sensors...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com