Biaxially oriented polyester film and method for manufacturing same

A technology of polyester film and biaxial orientation, applied in the field of polyester film, can solve problems such as easy dissolution of oligomers, reduction of film appearance quality, and damage to the flavor of the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0175] Using a single-screw extruder, melt PBT-1 and silica particles having an average particle diameter of 2.4 μm as inert particles so that the silica concentration becomes 1600 ppm and melt at 270° C. The melt line leads to a 12 element static mixer. In this way, the polybutylene terephthalate melt is divided and stacked, and a multilayer melt made of the same raw material is obtained. It was cast from a T-die at 270° C., and adhered to a cooling roll at 15° C. by an electrostatic bonding method to obtain an unstretched sheet.

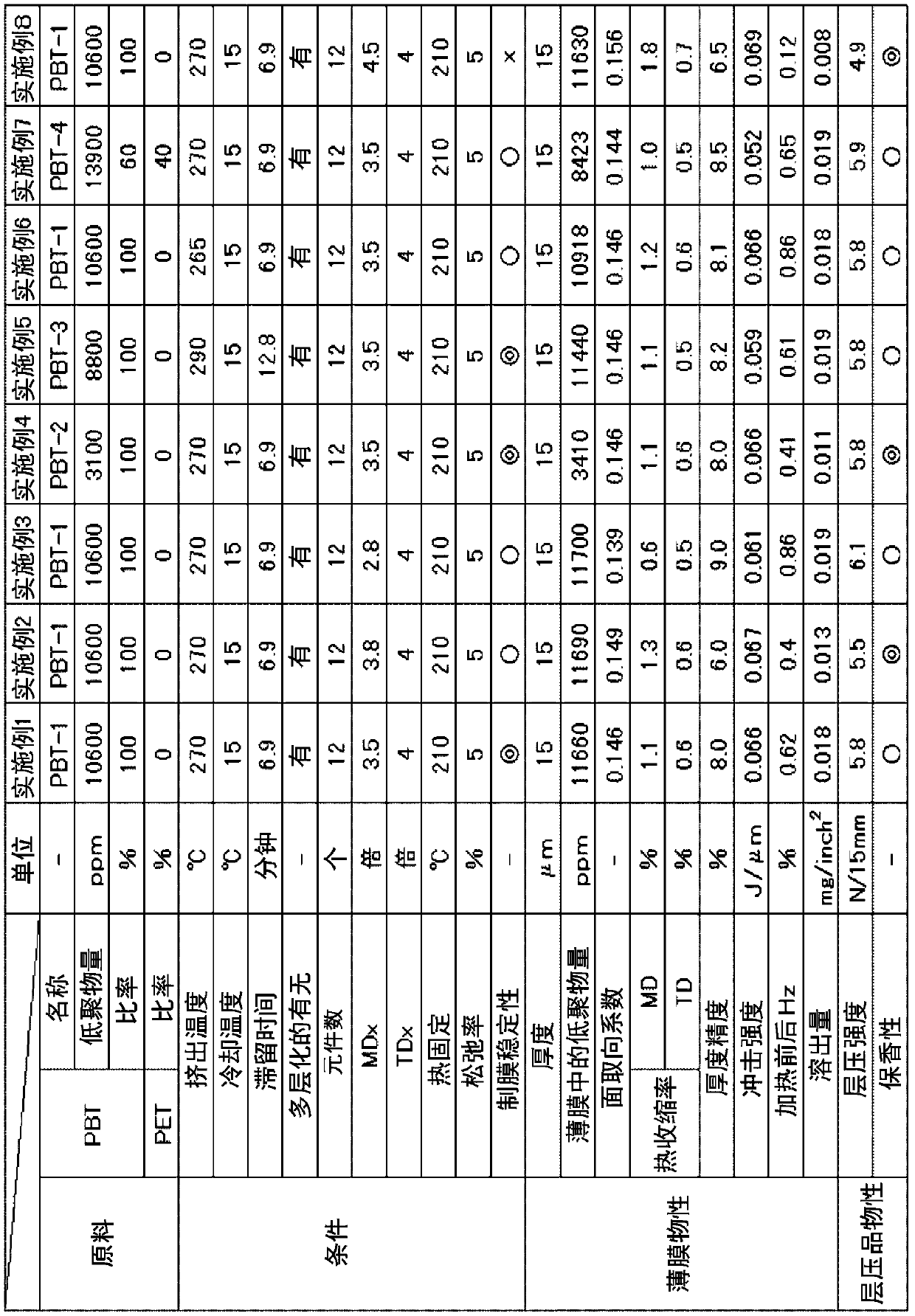

[0176] Next, 3.5-fold roll stretching was carried out in the machine direction (MD) at 60°C, followed by 4.0-fold stretching in the transverse direction (TD) at 90°C by a tenter, and a tension heat treatment was performed at 210°C for 3 seconds and 1 After a 5% relaxation process for a second, 10% of the holding portions at both ends were cut and removed to obtain a mill roll of a polybutylene terephthalate film having a thickness of 15 μm. Table...

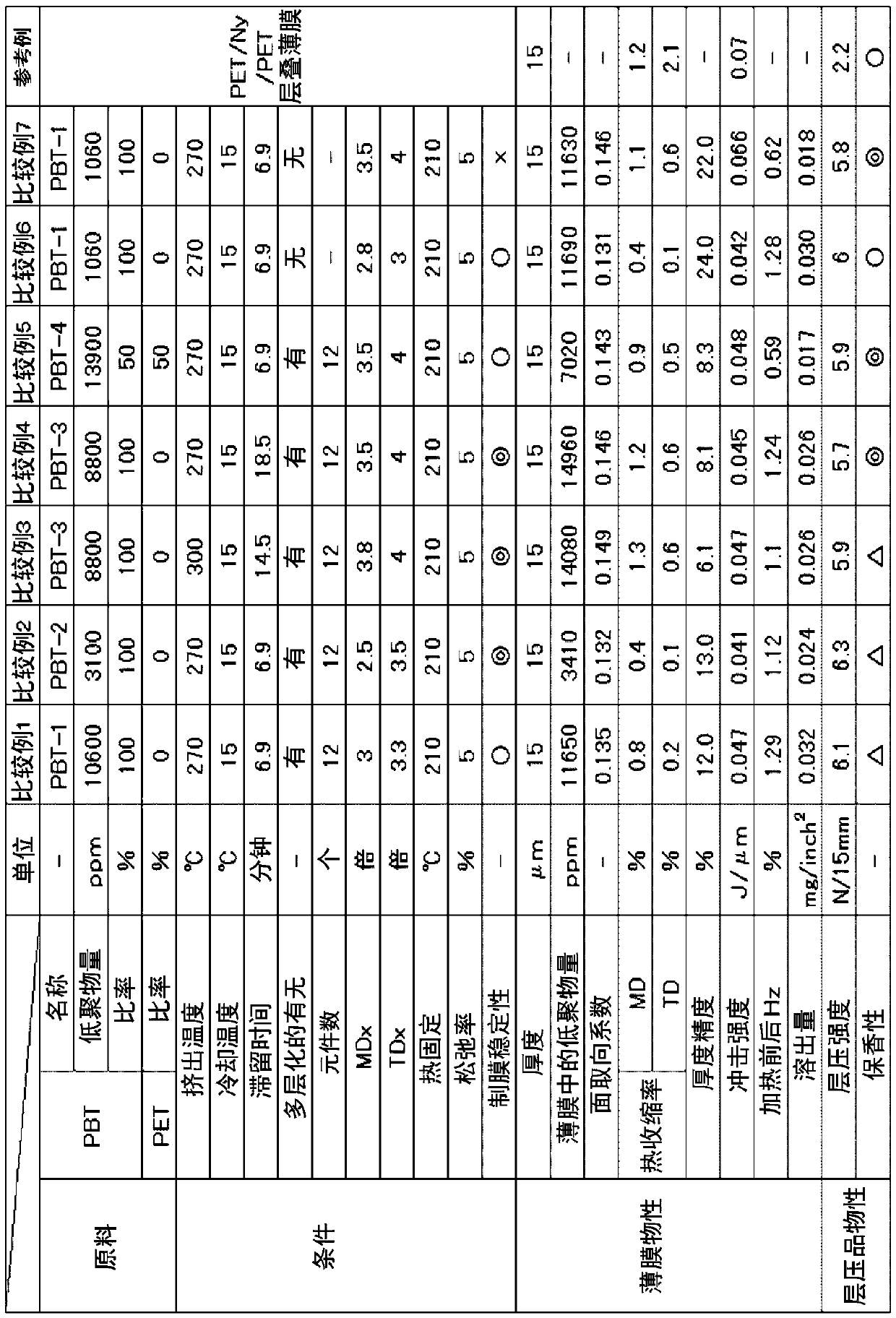

Embodiment 2~7、 comparative example 1~5

[0178] In Example 1, the polybutylene terephthalate resin used, the composition of raw materials, and the film-forming conditions were changed to the biaxially stretched film recorded in Table 1 or Table 2. In addition, the same as in Example 1 Do the same. Table 1 or Table 2 shows the film forming conditions, physical properties, and evaluation results of the obtained film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com