Efficient membrane distillation assembly for desulfurization wastewater treatment

A desulfurization wastewater and high-efficiency membrane technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve problems such as expensive equipment, high energy consumption, and pressure difference. Achieve the effect of reducing flux loss, improving efficiency and reducing bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

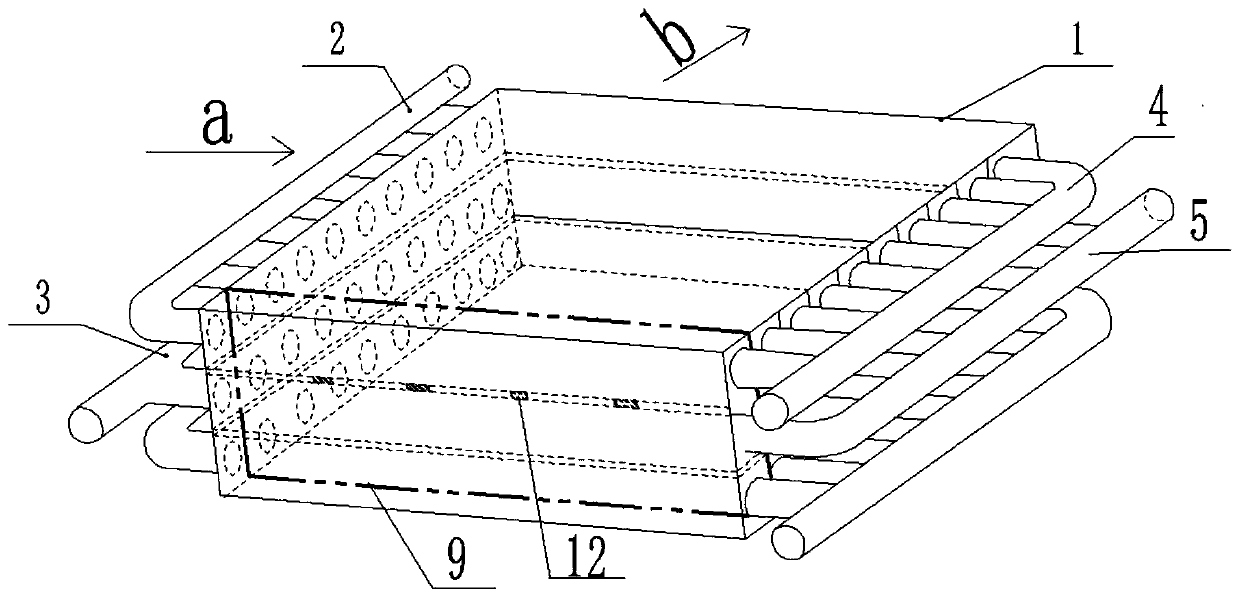

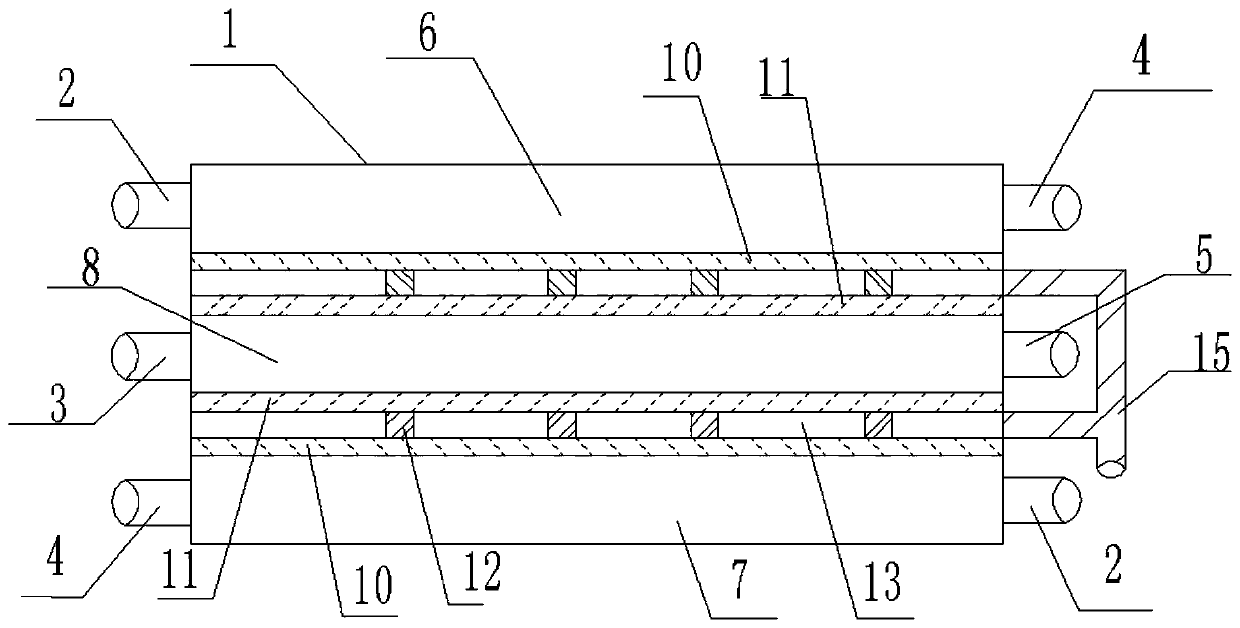

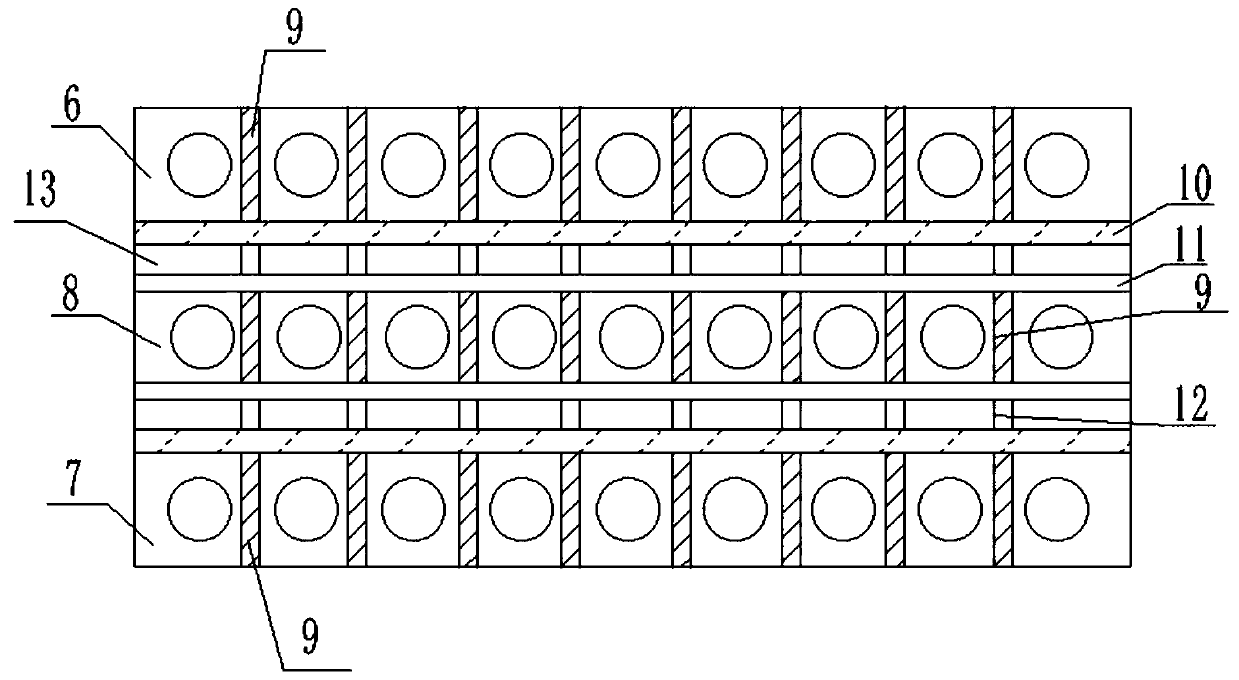

[0021] Such as Figure 1-3 As shown, the present invention includes a housing 1, and the housing 1 is provided with two layers of horizontally arranged cold walls 10 to divide the inner cavity of the housing 1 into an upper cold flow area 6, a hot flow area 8 and an upper cold flow area from top to bottom. The lower cold flow area 7, the hot flow area 8 is between the upper cold flow area 6 and the lower cold flow area 7, which can better utilize the heat of the hot liquid in the hot flow area 8 and reduce heat loss; the upper cold flow area In the area 6, the hot flow area 8 and the lower cold flow area 7, a plurality of partitions 9 are arranged side by side along the direction of fluid flow, and the partitions 9 separate the upper cold flow area 6, the hot flow area 8 and the lower cold flow area 7. Evenly divided into multiple parallel flow channels, which can increase the flux, improve the flow state of the liquid, facilitate the mass transfer process, improve the efficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com