Preparation process for metal rubber damping sandwich plate based on vacuum electron beam welding

A vacuum electron beam, metal rubber technology, applied in electron beam welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of low interface bonding strength, limited large-size sandwich panel preparation and application, small product specifications, etc. , to achieve the effect of good weld consistency and organizational performance, strong controllability of the production process, and simple structure of production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

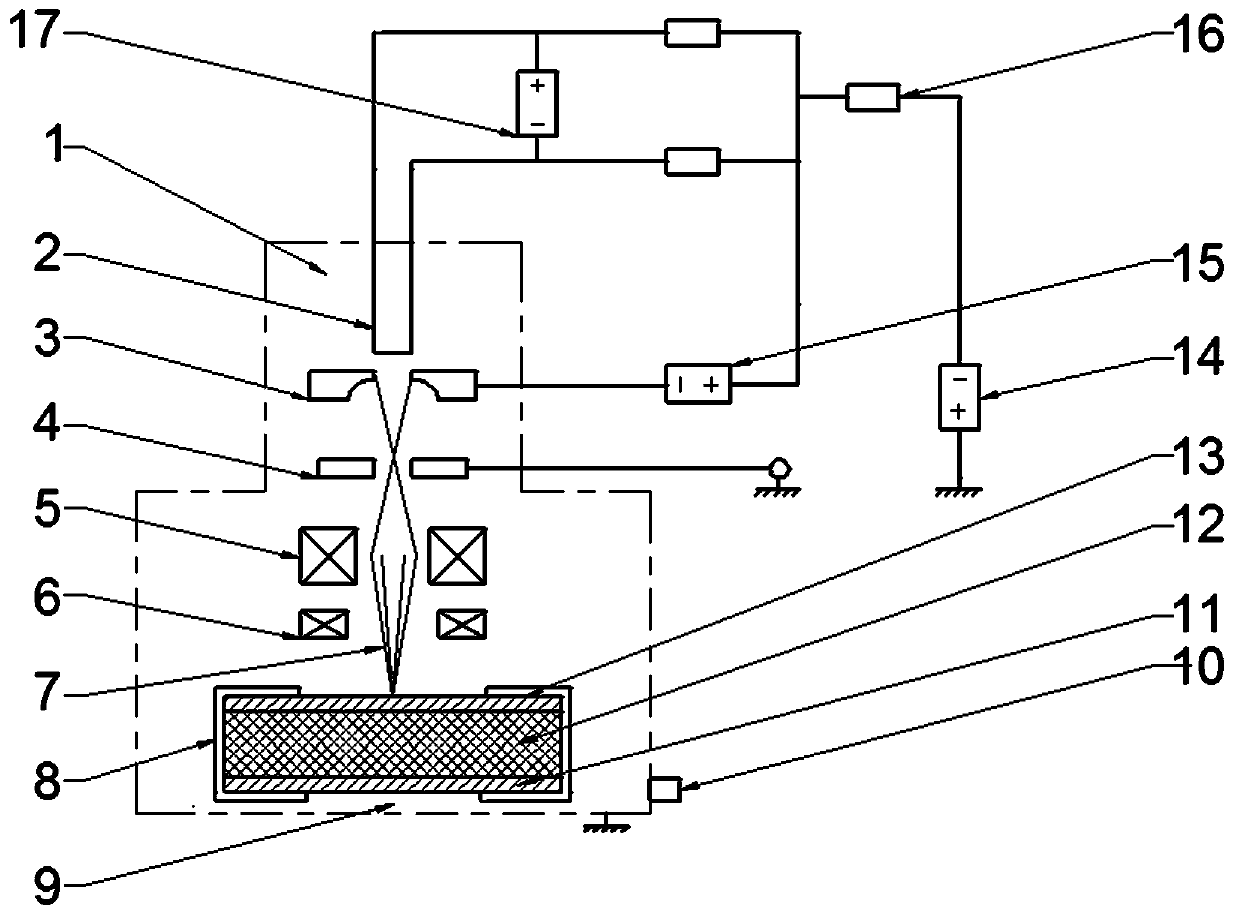

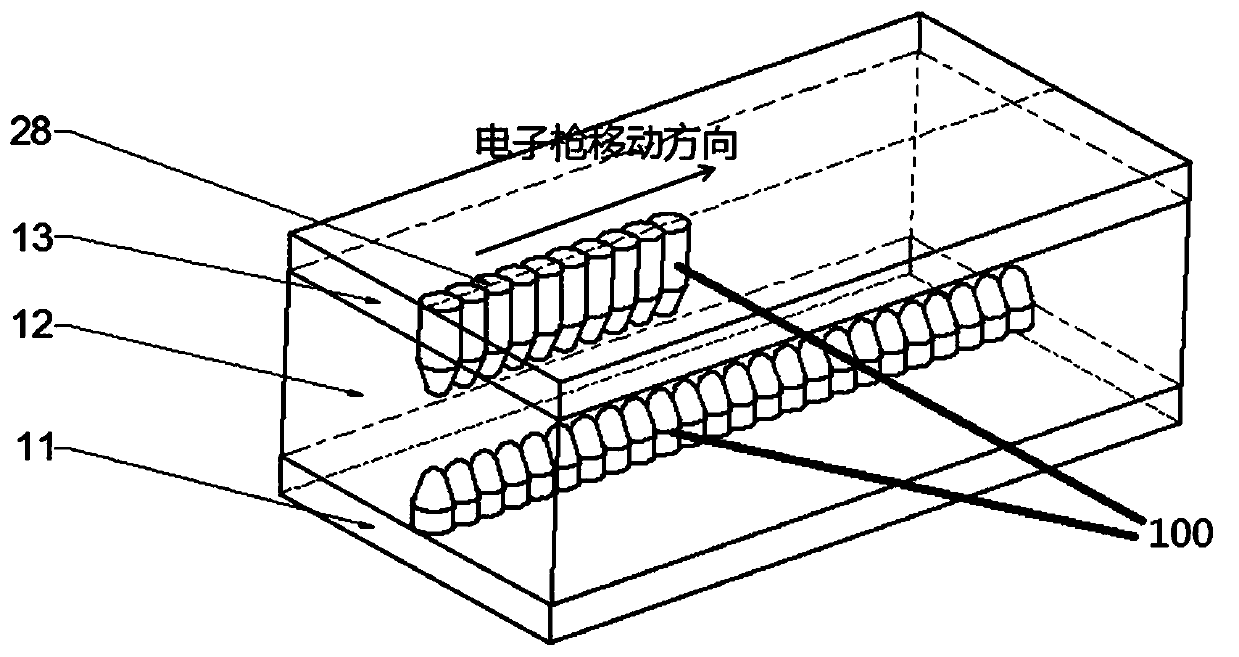

[0036] Such as Figure 1-5 As shown, the preparation process of the metal rubber damping sandwich panel based on vacuum electron beam welding, the upper panel 13 and the lower panel 11 of the sandwich panel are all metal plates, and the core material 12 is woven with metal wire and has a space Metal rubber with mesh structure; the process is used to cover the surface of the metal rubber with a welding process to prepare a high damping sandwich panel structure, and the process includes the following steps;

[0037] A1. Clean the plate and core material with ultrasonic waves until the oxides and impurities on the welding surface of the plate and core material are removed;

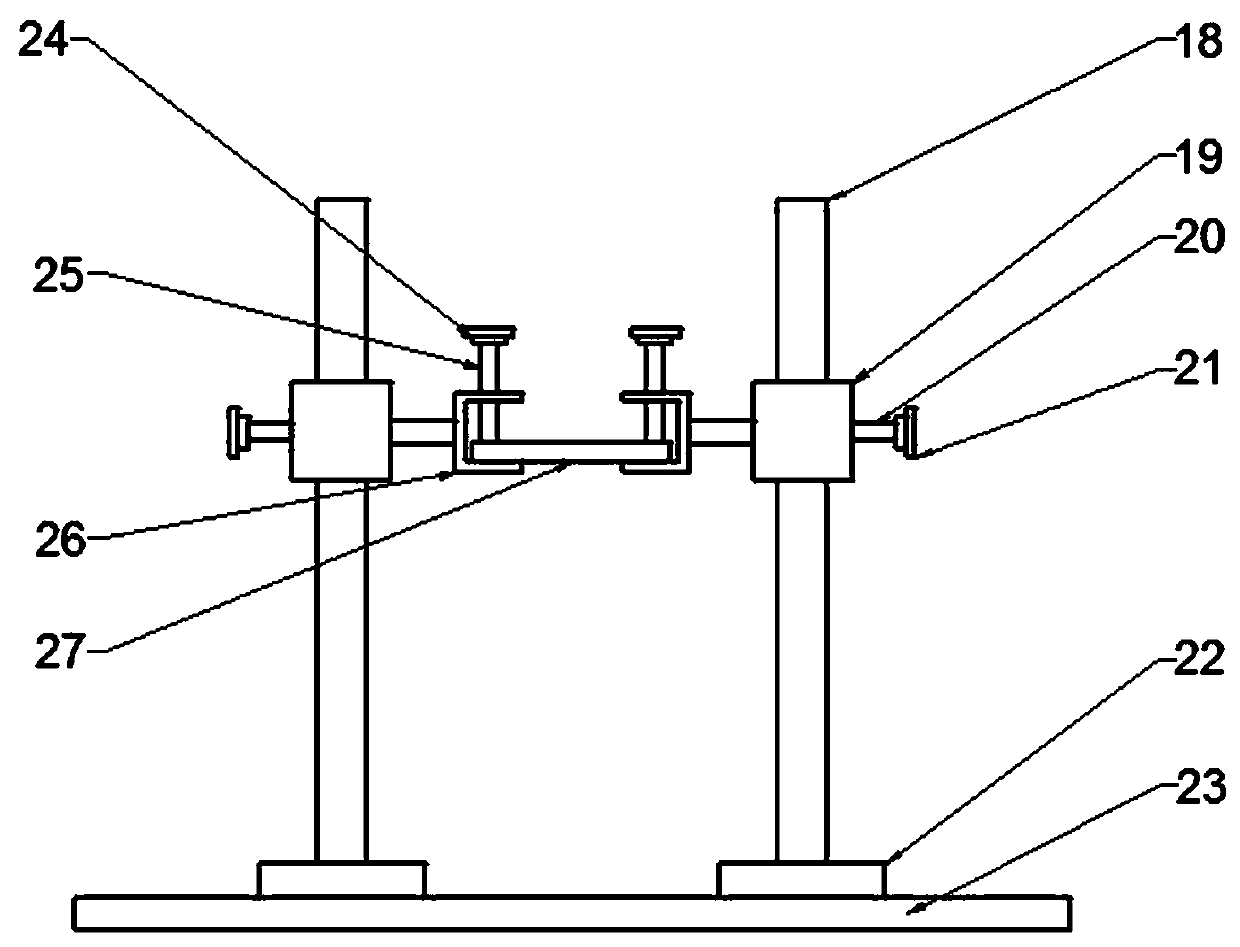

[0038] A2. Assemble the plate and core material, and fix the plate and core material with welding fixture 8 to form a piece to be welded, move the piece to be welded to the vacuum chamber 9, and evacuate the vacuum chamber with the exhaust device 10;

[0039] A3. After preheating the welding position 28 betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com