Cutting and polishing equipment for building stone

A stone cutting and equipment technology, applied in stone processing equipment, grinding/polishing equipment, stone processing tools, etc., can solve the problems of low automation, complex and cumbersome process, narrow application range, etc., and achieve strong versatility and adjustable Spacious, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

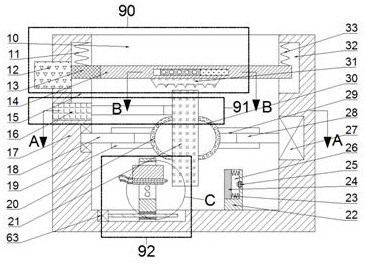

[0025] Combine below Figure 1-6 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

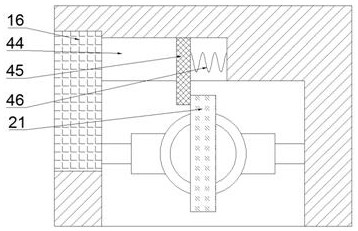

[0026] combined with Figure 1-6 The cutting and polishing equipment for building stones includes a fuselage 17, the fuselage 17 is provided with a working chamber 10 with an upward opening and a forward opening, and a marble block 21 can be installed in the working chamber 10;

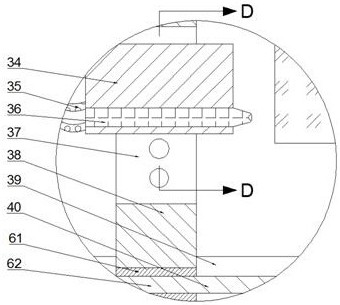

[0027] The bottom wall of the working chamber 10 is provided with a first chute 39 with an upward opening, and a first sliding plate 38 is slid in the first chute 39, and a first sliding cavity penetrating left and right is provided in the first sliding plate 38. 37. A slider 34 is slidably provided in the first sliding cavity 37, and a cutting mechanism 92 for cutting the marble block 21 into a circle is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com