Lactating sow feed formula design and preparation method thereof

A technology for lactating sows and formula, applied in chemical instruments and methods, feed, animal feed, etc., can solve the problems of low fiber content, insufficient addition of functional raw materials, nutritional imbalance of sows, etc., to improve enzyme activity, effectively Conducive to the balance of nutrient absorption and the effect of increasing body weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

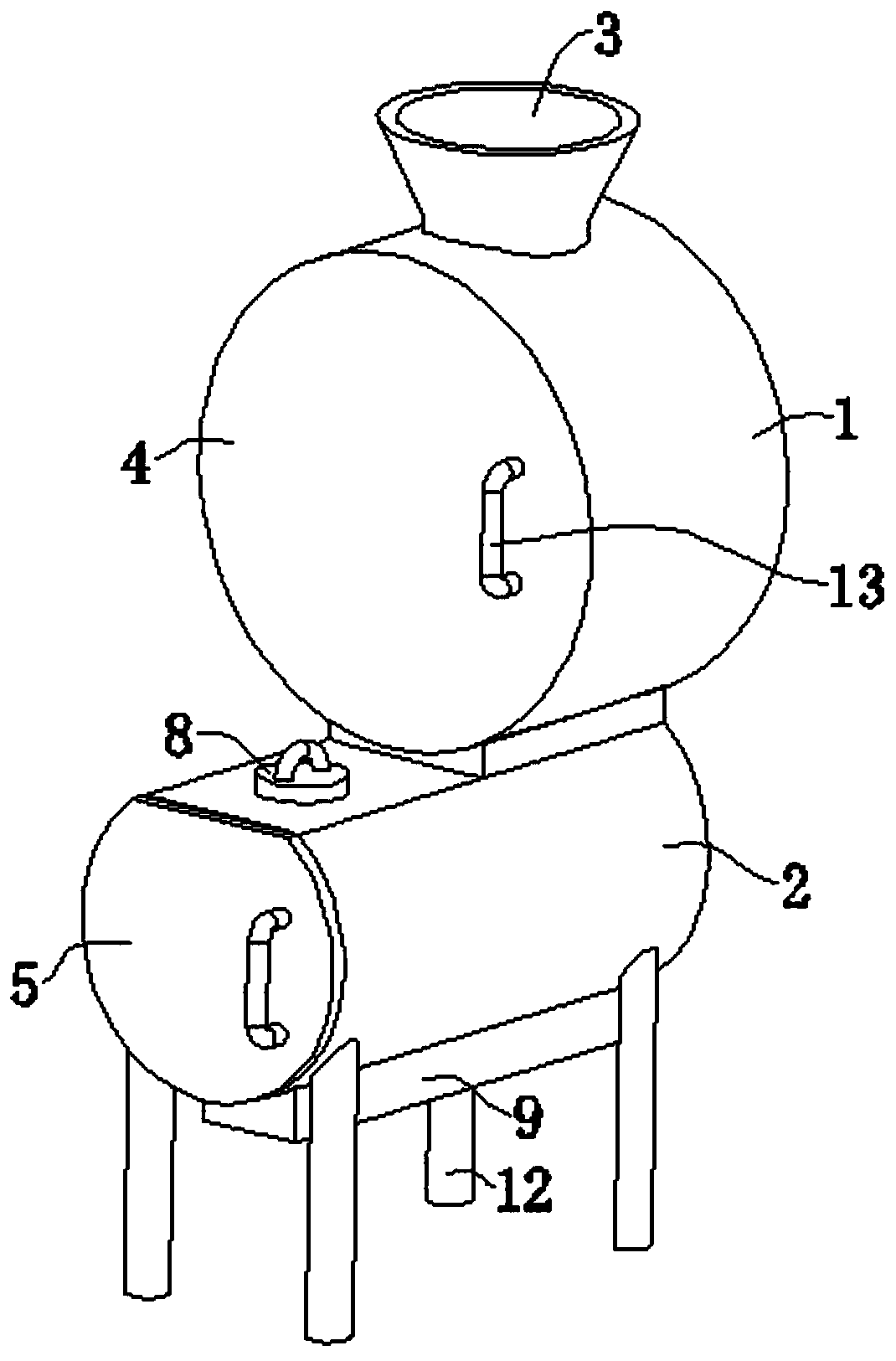

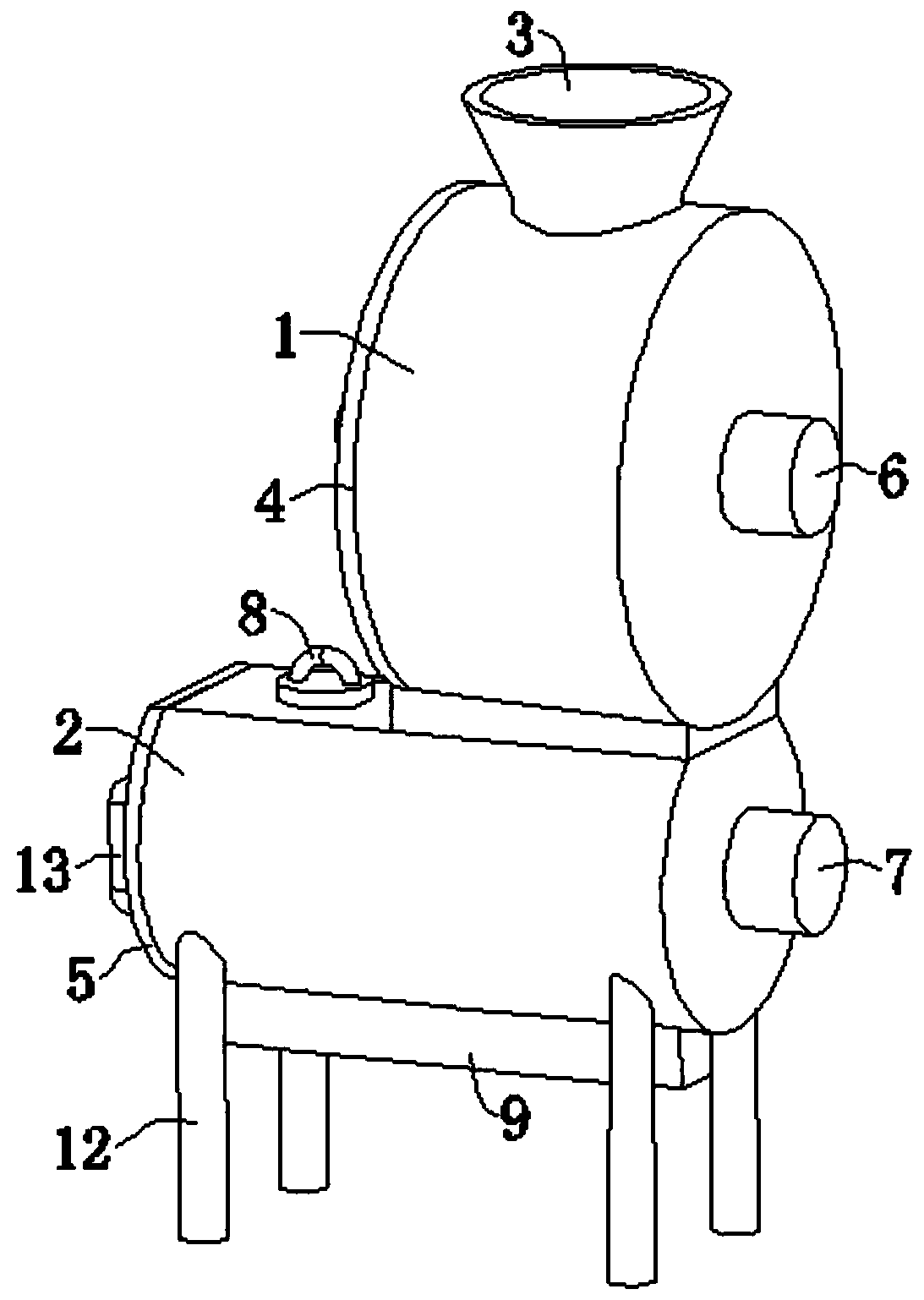

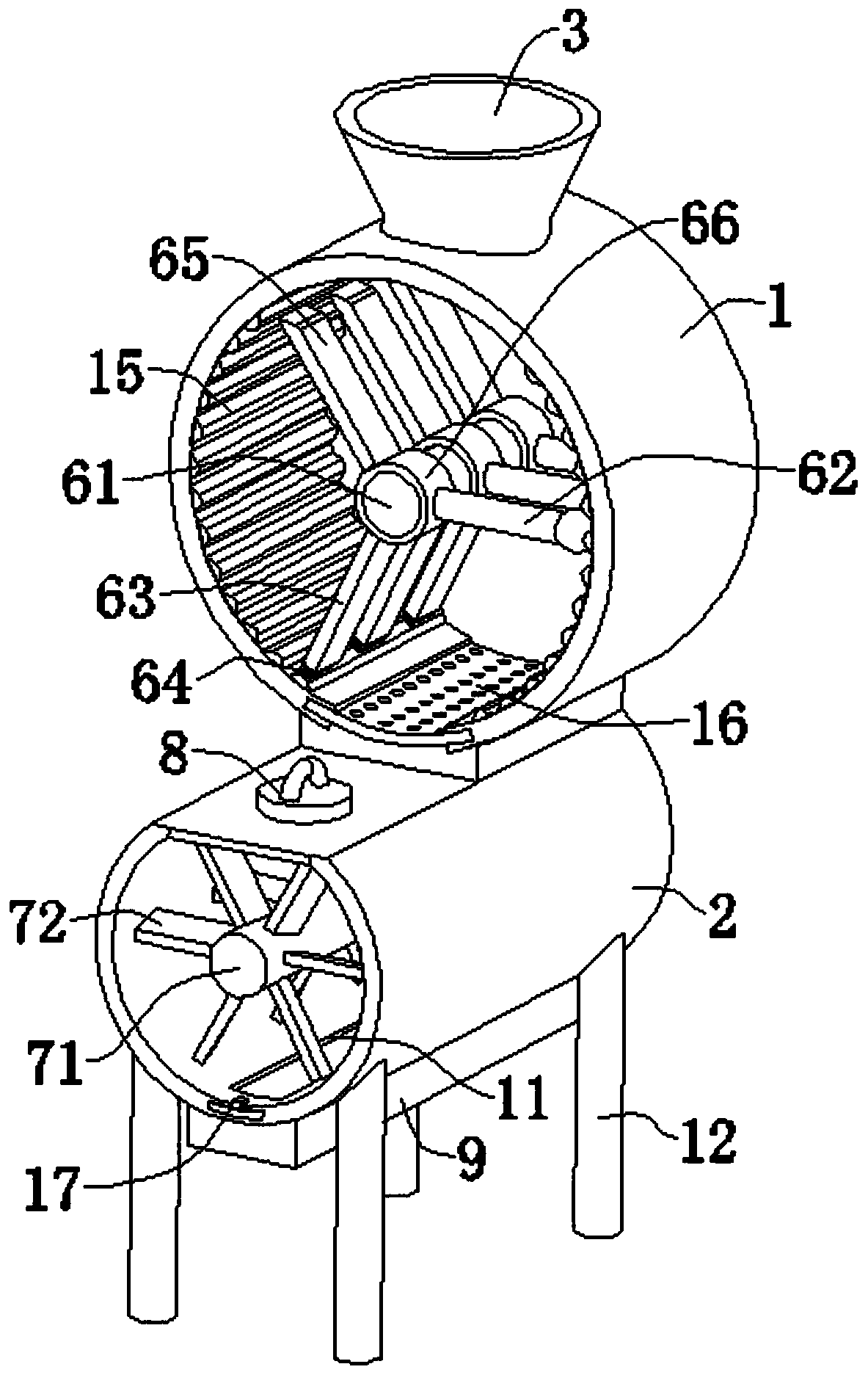

Image

Examples

Embodiment 1

[0082] Example 1: Formula design and preparation method of feed for lactating sows. The feed for nursing sows includes corn, wheat bran and concentrated core material, and the mass ratio of corn, wheat bran and concentrated core material is 60:25:15;

[0083] The concentrated core material includes the following raw material components and mass parts:

[0084] Cellulose: 12 parts;

[0085] Expanded soybeans: 25 parts;

[0086] Fish meal: 10 parts;

[0087] Stone powder: 10 parts;

[0088] Phosphorous calcium: 7 parts;

[0089] Oil powder: 20 parts;

[0090] Breeding pig multi-mine: 2 parts;

[0091] Soybean oil: 2 parts;

[0092] Sodium chloride: 2 parts;

[0093] Baking soda: 2 parts;

[0094] Potassium chloride: 2 parts;

[0095] Amino acid composition: 4 parts;

[0096] Chinese medicine components: 0.8 parts;

[0097] Organic polymineral: 2 parts;

[0098] Probiotics: 0.2 parts;

[0099] Phytase: 0.2 parts;

[0100] Compound enzyme: 0.2 parts;

[0101] Vitami...

Embodiment 2

[0129] Embodiment 2: A formula design and preparation method of lactating sow feed. The difference from Example 1 is that the concentrated core feed includes the following raw material components and parts by mass:

[0130] Cellulose: 10 parts;

[0131] Puffed soybeans: 20 parts;

[0132] Fish meal: 8 servings;

[0133] Stone powder: 8 parts;

[0134] Phosphorous calcium: 5 parts;

[0135] Oil powder: 10 parts;

[0136] Breeding pig multimineral: 1 part;

[0137] Soybean oil: 1 part;

[0138] Sodium chloride: 1 part;

[0139] Baking soda: 1 part;

[0140] Potassium chloride: 1 part;

[0141] Amino acid composition: 2 parts;

[0142] Chinese medicine components: 0.5 parts;

[0143] Organic polymineral: 1 part;

[0144] Probiotics: 0.1 parts;

[0145] Phytase: 0.1 parts;

[0146] Compound enzyme: 0.1 part;

[0147] Vitamin C: 0.1 parts;

[0148] Vitamin E: 0.1 parts;

[0149] Mold remover: 0.1 parts;

[0150] Antioxidant: 0.1 parts;

[0151] Antifungal agent: 0...

Embodiment 3

[0165] Embodiment 3: A formulation design and preparation method of lactating sow feed. The difference from Example 1 is that the concentrated core feed includes the following raw material components and parts by mass:

[0166] Cellulose: 20 parts;

[0167] Puffed soybeans: 30 parts;

[0168] Fish meal: 15 parts;

[0169] Stone powder: 15 parts;

[0170] Phosphorous calcium: 10 parts;

[0171] Oil powder: 30 parts;

[0172] Breeding pig multi-mine: 3 parts;

[0173] Soybean oil: 5 parts;

[0174] Sodium chloride: 5 parts;

[0175] Baking soda: 5 parts;

[0176] Potassium chloride: 5 parts;

[0177] Amino acid composition: 5 parts;

[0178] Chinese medicine components: 1.0 parts;

[0179] Organic polymineral: 3 parts;

[0180] Probiotics: 0.3 servings;

[0181] Phytase: 0.3 parts;

[0182] Compound enzyme: 0.3 parts;

[0183] Vitamin C: 0.3 parts;

[0184] Vitamin E: 0.3 parts;

[0185] Mold remover: 0.3 parts;

[0186] Antioxidant: 0.3 parts;

[0187] Antifun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com