Method for applying tobacco powder to paper-making reconstituted tobacco

A technology for reconstituting tobacco leaves and papermaking method, which is applied in the field of new product quality improvement technology, can solve the problems such as difficulty in further improving the use effect and utilization rate of tobacco powder, and achieves improved sensory smoking quality, improved utilization efficiency, steps and process operations simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below in conjunction with accompanying drawing embodiment:

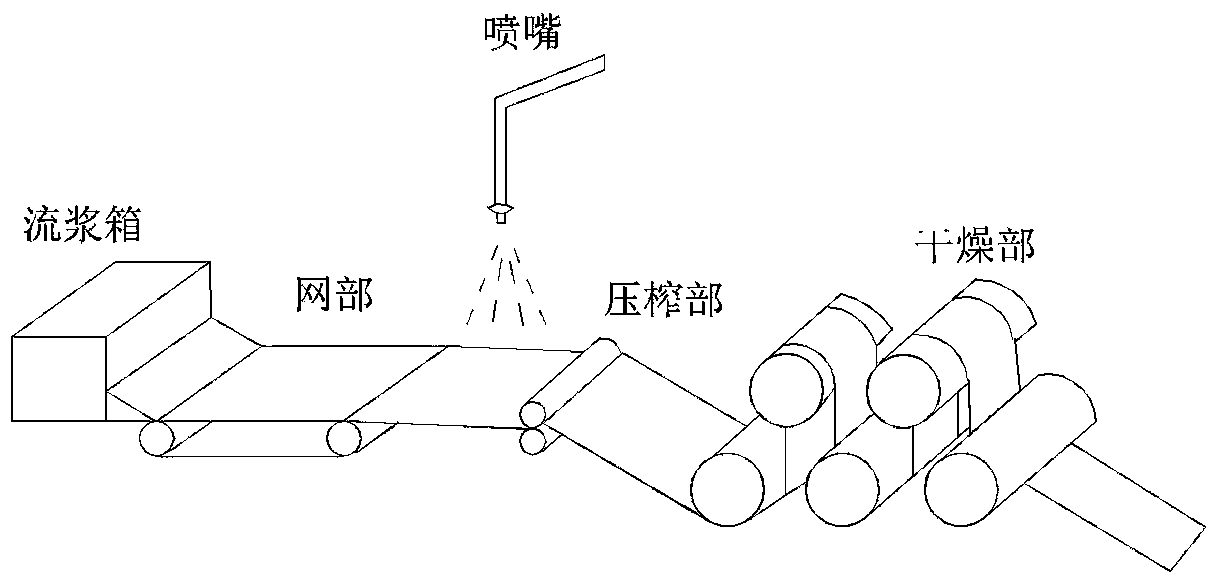

[0030] Such as figure 1 Shown: A method of applying smoke powder to reconstituted tobacco leaves of the papermaking method according to the present invention is to inject smoke powder into the tail of the paper machine by spraying the nozzle system between the forming part and the pressing part of the papermaking process The surface of the reconstituted tobacco leaf base sheet, and the pressing section immediately presses the base sheet with tobacco powder attached to effectively improve the surface properties and internal structure of the paper base.

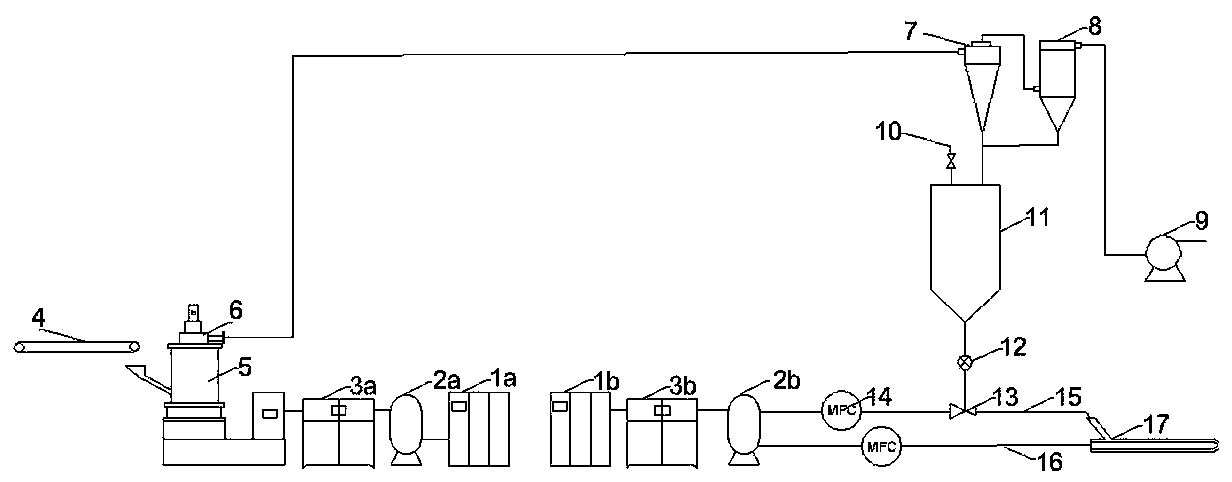

[0031] The present invention is further described from the preparation of smoke powder to the injection process in conjunction with the accompanying drawings:

[0032] Such as figure 2 As shown: the high-temperature and high-pressure air produced by the air compressor 1a of the airflow grinding and classification sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com