A kind of clay solidifying agent and its preparation method and use method

A technology of curing agent and clay, applied in the field of clay curing agent and its preparation, can solve the problems of storage stability, permeability and diffusivity of curing agent and poor environmental protection, and achieve excellent biodegradability, good degradability, water solubility, etc. Good performance and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

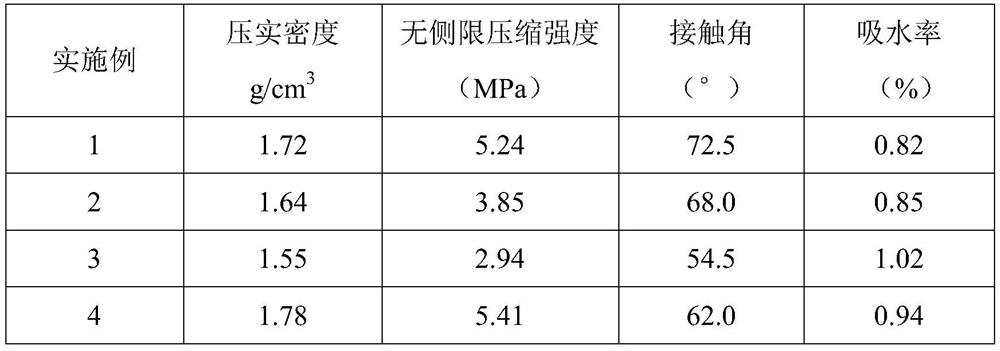

Examples

Embodiment 1

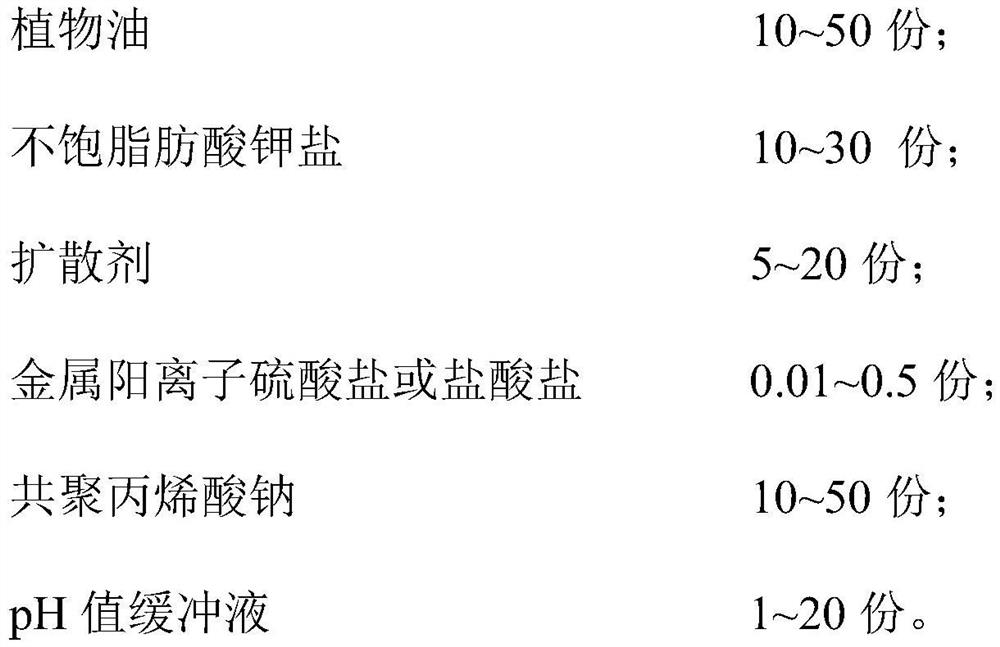

[0054] A clay curing agent, including the raw materials of the following mass components: 10 parts of vegetable oil mixed with tung oil and linseed oil at a ratio of 5:1, 10 parts of potassium oleate, OP-10, Tween-81 and lauryl Dimethylsulfoethyl betaine mixed at 1:1:0.1 is 5 parts of diffusing agent, 2.5 parts of 20%wt aluminum sulfate solution, 10 parts of sodium copolyacrylate, and 20 parts of pH value buffer solution with pH=6.5.

[0055] The preparation method of above-mentioned clay solidifying agent, comprises the following steps:

[0056] Mixing and stirring the pH buffer solution and sodium copolyacrylate according to mass components to obtain component A;

[0057] Mix the diffusing agent, unsaturated fatty acid potassium salt and vegetable oil according to mass components, heat to 50±5°C and stir evenly, then add dropwise 20%wt metal cation sulfate or hydrochloride solution, and stir to obtain component B;

[0058] Add component A to component B dropwise, keep a con...

Embodiment 2

[0065] A clay curing agent, including raw materials with the following mass components: 50 parts of vegetable oil mixed with tung oil and linseed oil at a ratio of 5:1, unsaturated potassium linoleate and potassium ricinoleate mixed at a ratio of 1:1 30 parts of potassium salt of fatty acid, 20 parts of diffusion agent mixed by Tuwen-81 and octadecyl dimethyl sulfoethyl betaine in 8:2, 20%wt aluminum chloride and ferric chloride solution (Al and The molar ratio of Fe is 1:1) 0.05 parts, 50 parts of sodium copolyacrylate, and 1 part of pH value buffer solution with pH=7.5.

[0066] The preparation method of above-mentioned clay solidifying agent is with embodiment 1.

[0067] The use method of above-mentioned clay solidifying agent in clay solidification, comprises the following steps:

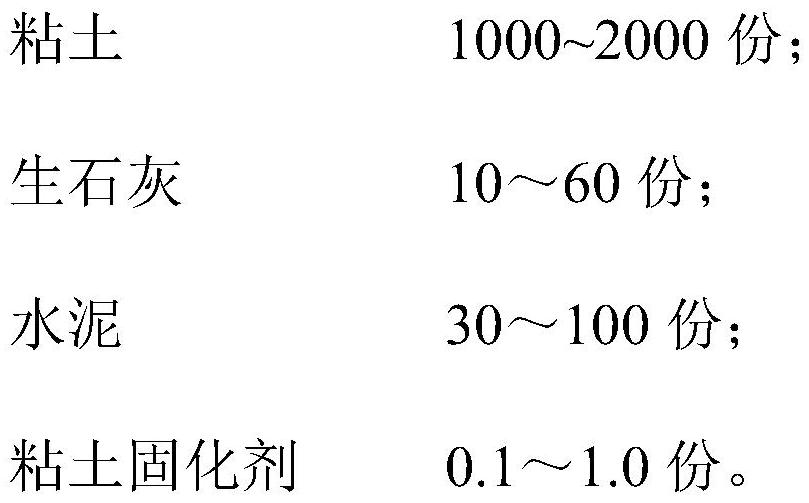

[0068] Mix 60 parts of quicklime with 2000 parts of clay A, stack and mature for 5 days under natural conditions to obtain mellow soil;

[0069] Stir and mix 100 parts of cement A, 0.8 parts ...

Embodiment 3

[0073] A clay curing agent, including raw materials with the following mass components: 30 parts of vegetable oil mixed with tung oil and catalpa oil at a ratio of 1:1, unsaturated potassium linoleate and potassium ricinoleate mixed at a ratio of 1:1 Fatty acid potassium salt 20 parts, OP-10, Twain-81, Span 80, dodecyl dimethyl sulfopropyl betaine mixed according to 1:1:1:0.1 15 parts of diffusing agent, 20% 1.0 parts of wt aluminum sulfate and iron sulfate solution (the molar ratio of Al to Fe is 1:1), 30 parts of sodium copolyacrylate, and 10 parts of pH buffer solution with pH=7.0.

[0074] The preparation method of above-mentioned clay solidifying agent is with embodiment 1.

[0075] The use method of above-mentioned clay solidifying agent in clay solidification, comprises the following steps:

[0076] Mix 50 parts of quicklime with 1500 parts of clay A, stack and mature for 4 days under natural conditions to obtain mellow soil;

[0077] Stir and mix 60 parts of cement A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com