High-strength slag-free burning product and preparation method thereof

A high-strength, slag technology, applied in the field of construction and materials, can solve the problems of high cost of building materials, pollution, large amount of solid waste, etc., and achieve the effect of improving long-term strength, reducing costs, and good anti-freeze and thawing characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] High-strength slag-free fired products

[0054] Including: blast furnace slag 300g, slag 900g (water content less than 3%), water glass 128g, NaOH 25.6g, water 38.4g;

[0055] The particle size distribution of the slag is that the coefficient of inhomogeneity is 6, and the coefficient of curvature is 2; the specific surface area of blast furnace slag is 400m 2 / kg of fine powder, the modulus of water glass is 2.8.

[0056] Preparation method of high-strength slag-soil unfired product

[0057] Air-dry the dregs, pulverize, sieve, control and adjust the particle size of the dregs to be less than 1 / 10 of the size of high-strength dregs unfired products, the particle size distribution is 6, the coefficient of curvature is 2; crush the blast furnace Slag to a specific surface area of 400m 2 / kg of fine powder, the slag and blast furnace slag are fully mixed, so that the blast furnace slag covers the surface of the slag to obtain a solid mixture;

[0058] Mix NaOH, wa...

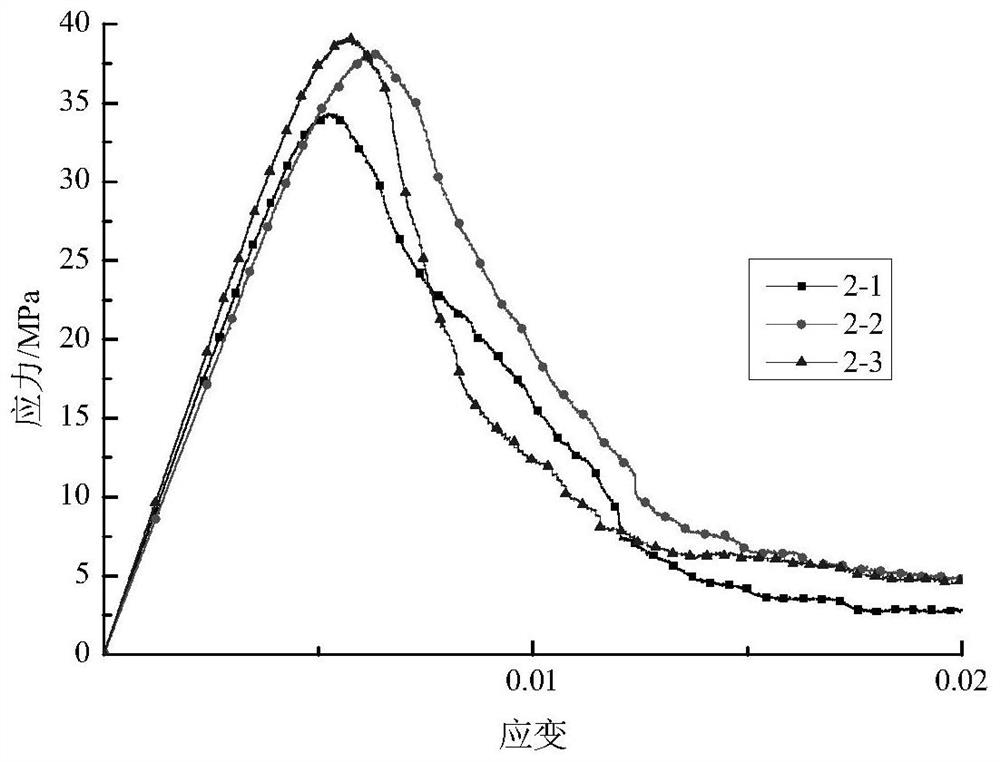

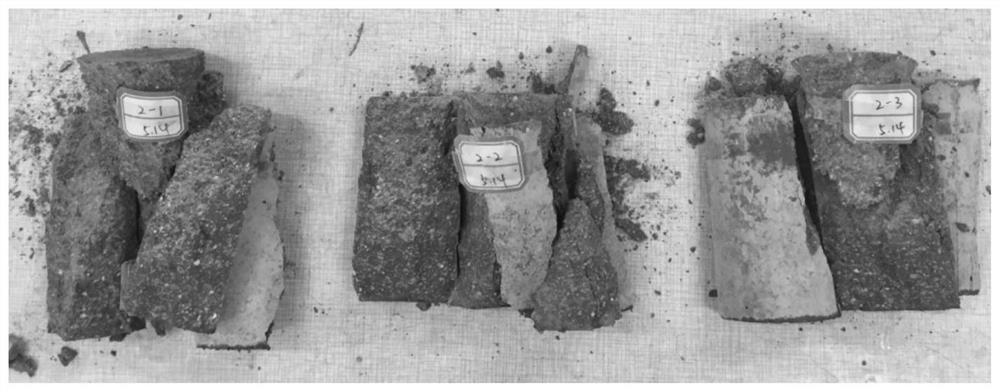

Embodiment 2

[0062] High-strength slag-free fired products

[0063] Including: 400g of blast furnace slag, 800g of slag (water content less than 3%), 128g of water glass, 30g of KOH, and 34g of water;

[0064] The particle size distribution of slag is 6.5 inhomogeneity coefficient and 1.5 in curvature coefficient; the specific surface area of blast furnace slag is 420m 2 / kg of fine powder, the modulus of water glass is 3.

[0065] Preparation method of high-strength slag-soil unfired product

[0066] Air-dry, pulverize and sieve the slag, control and adjust the particle size of the slag to be less than 1 / 10 of the size of the high-strength slag unfired product, the particle size distribution is 6.5, and the curvature coefficient is 1.5; Slag to specific surface area is 420m 2 / kg of fine powder, the slag and blast furnace slag are fully mixed, so that the blast furnace slag covers the surface of the slag to obtain a solid mixture;

[0067] Mix KOH, water glass and water, let it stan...

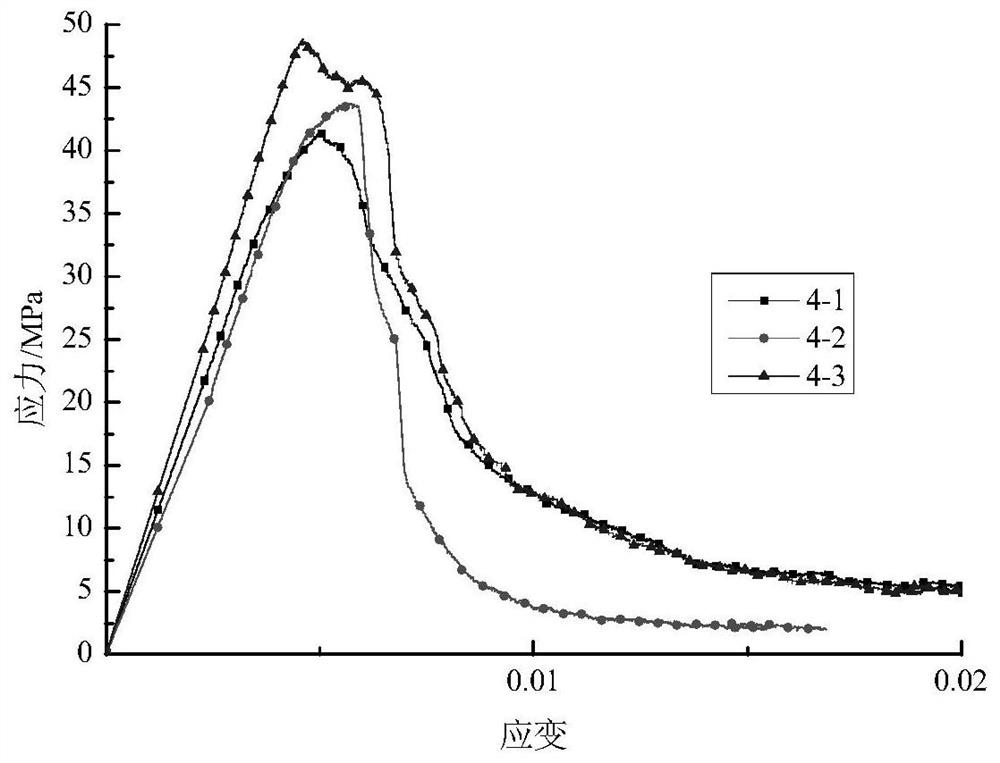

Embodiment 3

[0071] High-strength slag-free fired products

[0072] Including: 480g of blast furnace slag, 720g of slag (water content less than 3%), 128g of water glass, 20.5g of NaOH, 43.5g of water;

[0073] The particle size distribution of the slag is 7 with a coefficient of inhomogeneity and a coefficient of curvature of 2.6; the specific surface area of blast furnace slag is 450m 2 / kg of fine powder, the modulus of water glass is 3.1.

[0074] Preparation method of high-strength slag-soil unfired product

[0075] Air-dry, pulverize and sieve the slag, control and adjust the particle size of the slag to be less than 1 / 10 of the size of the high-strength slag unfired product, the particle size distribution is 7, the coefficient of curvature is 2.6; crush the blast furnace Slag to specific surface area is 450m 2 / kg of fine powder, the slag and blast furnace slag are fully mixed, so that the blast furnace slag covers the surface of the slag to obtain a solid mixture;

[0076] Mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com