A kind of instantaneous high temperature resistant flexible adhesive and its preparation method

A high-temperature flexible and adhesive technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of organic silicone adhesive bubbles, macula, and inability to meet more stringent use requirements, and achieve anti-aging Strong impact and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

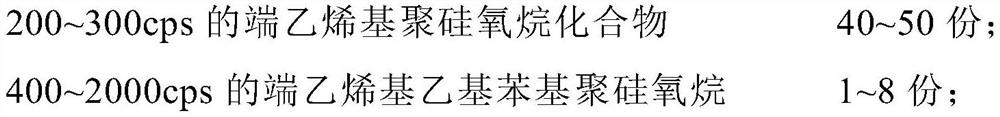

[0023] 1) Weigh 40 parts of 200cps-terminated vinylpolysiloxane compound and 1 part of 1000cps-terminated vinylethylphenylpolysiloxane in parts by weight, heat to 100°C and stir for 3 hours under the protection of inert gas, Cool to room temperature, add 3 parts of silicon carbide, and stir for 3.5 hours to obtain a colorless and transparent liquid of component A, which is sealed under the protection of an inert gas. Vinyl polysiloxane, vinyl-terminated ethylphenyl polysiloxane is a single-end vinyl-containing ethylphenyl polysiloxane with a vinyl content of 4%;

[0024] 2) Weigh 15 parts of methylphenylpolysiloxane with a hydrogen content of 5% and 0.01 part of Castel catalyst with a mass fraction of platinum of 0.2% in parts by weight, and add them to the reaction device under nitrogen protection After stirring, heat to 70°C, stir for 4 hours, and cool to room temperature to obtain a colorless and transparent liquid of component B, which is sealed under the protection of an ...

Embodiment 2

[0027] 1) Weigh 45 parts of 200cps-terminated vinylpolysiloxane compound and 8 parts of 400cps-terminated vinylethylphenylpolysiloxane in parts by weight, heat to 100°C and stir for 3 hours under the protection of inert gas, Cool to room temperature, add 3 parts of silicon carbide, and stir for 3.5 hours to obtain component A colorless transparent liquid, which is sealed under the protection of an inert gas; wherein, the vinyl-terminated polysiloxane compound is a single-terminal polysiloxane compound with a vinyl content of 2%. Vinyl polysiloxane, vinyl-terminated ethylphenyl polysiloxane is vinyl-terminated ethylphenyl polysiloxane with a vinyl content of 5%;

[0028] 2) Weigh 15 parts of methylphenylpolysiloxane with a hydrogen content of 5% and 0.01 part of Castel catalyst with a mass fraction of platinum of 0.2% in parts by weight, and add them to the reaction device under nitrogen protection After stirring, heat to 70°C, stir for 4 hours, and cool to room temperature to ...

Embodiment 3

[0031] 1) Weigh 45 parts of 300cps-terminated vinylpolysiloxane compound and 6 parts of 600cps-terminated vinylethylphenylpolysiloxane in parts by weight, heat to 100°C and stir for 3 hours under the protection of inert gas, Cool to room temperature, add 4 parts of silicon carbide, and stir for 3.5 hours to obtain a colorless and transparent liquid of component A, which is sealed under the protection of an inert gas; wherein, the vinyl-terminated polysiloxane compound is a single-terminal polysiloxane compound with a vinyl content of 1.5%. Vinyl polysiloxane, vinyl-terminated ethylphenyl polysiloxane is a single-end vinyl-containing ethylphenyl polysiloxane with a vinyl content of 4.5%;

[0032] 2) Weigh 15 parts of methylphenyl polysiloxane with a hydrogen content of 5% and 0.09 parts of a Castel catalyst with a mass fraction of 0.2% of platinum in parts by weight, and add them to the reaction device under nitrogen protection After stirring, heat to 70°C, stir for 4 hours, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com