Method for preparing superhydrophilic/subaqueous superoleophobic modified substrate material

An underwater super-oleophobic and base material technology, applied in the field of polymer materials, can solve the problems of many steps, harsh chemical conditions, and complicated, etc., and achieve the effect of simple coating process, easy to obtain, and stable coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

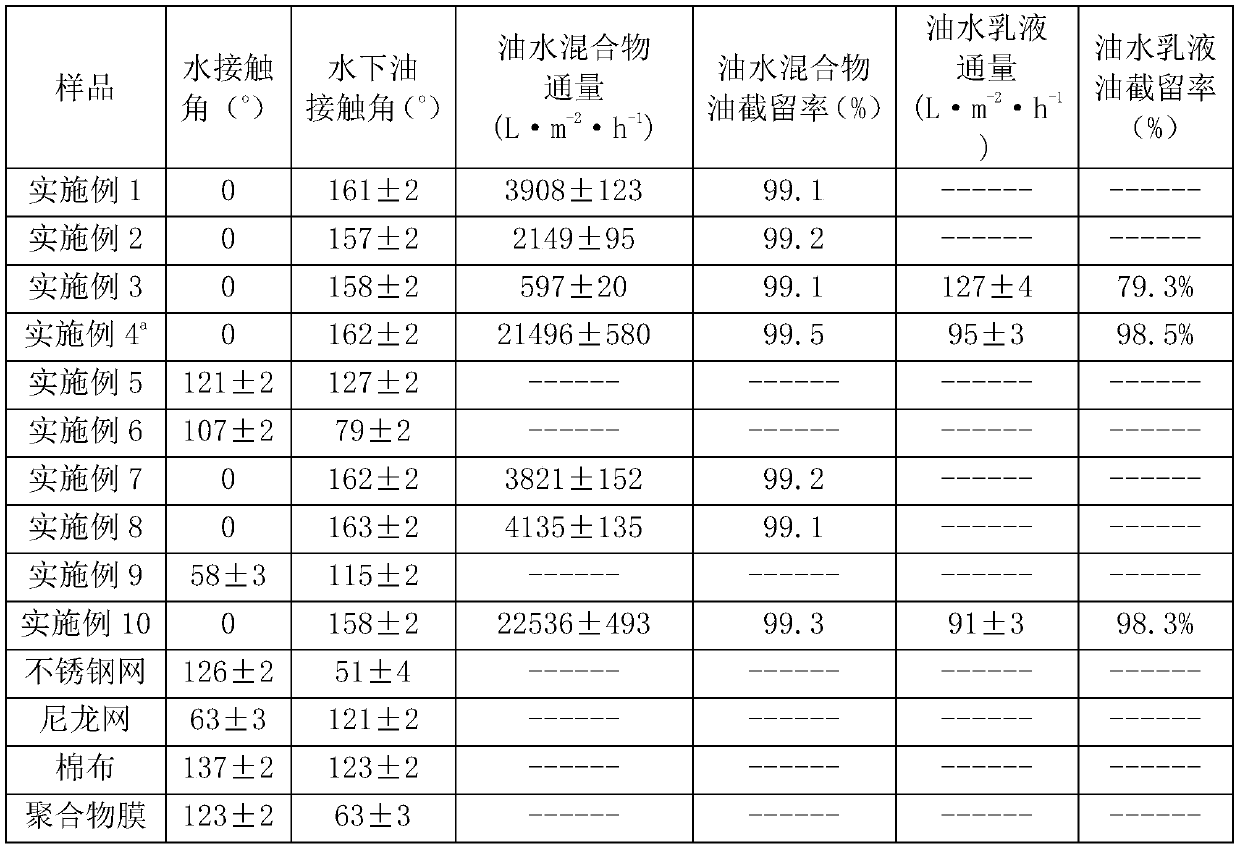

Examples

preparation example Construction

[0025] The present invention provides a method for preparing a superhydrophilic / underwater superoleophobic modified base material, which comprises the following steps:

[0026] Step 1, respectively preparing a certain concentration of styrene maleic anhydride copolymer solution and polyethyleneimine solution;

[0027] Step 2: Immerse the base material in the styrene maleic anhydride copolymer solution for a certain period of time, take it out and drain, and then immerse it in the polyethyleneimine solution for a certain period of time. Modified substrate material with superoleophobic properties.

[0028] In step 1, the described styrene maleic anhydride copolymer solution is a solution formed by dissolving styrene maleic anhydride copolymer in tetrahydrofuran, N,N-dimethylformamide or acetone solvent, and its solution concentration is 0.1 -30% (wt%).

[0029] In step 1, the polyethyleneimine solution is a solution formed by dissolving polyethyleneimine in deionized water, an...

Embodiment 1

[0037] A method for preparing a modified stainless steel screen with super-hydrophilic / underwater super-oleophobic properties that can be used for the treatment of oily wastewater, comprising the following steps:

[0038] (1) dissolving styrene maleic anhydride copolymer with a molecular weight of 1600 g / mol in N,N-dimethylformamide to prepare a 2% polymer solution;

[0039] (2) dissolving polyethyleneimine with a molecular weight of 10000 g / mol in deionized water to prepare a 2% polymer solution;

[0040] (3) Immerse the stainless steel mesh in the styrene maleic anhydride copolymer solution, stay for 10s, take out the drained solution, continue to immerse it in the polyethyleneimine solution, stay for 30min, take out the drained solution, and wash it with water.

Embodiment 2

[0042] A preparation method of a modified nylon mesh having super-hydrophilic / underwater super-oleophobic properties and can be used for the treatment of oily wastewater, comprising the following steps:

[0043] (1) dissolving a styrene maleic anhydride copolymer with a molecular weight of 1700 g / mol in tetrahydrofuran to prepare a 2% polymer solution;

[0044] (2) dissolving polyethyleneimine with a molecular weight of 5000 g / mol in deionized water to prepare a 2% polymer solution;

[0045] (3) Immerse the nylon mesh in the styrene maleic anhydride copolymer solution, stay for 20s, take out the drained solution, continue to immerse it in the polyethyleneimine solution, stay for 60min, take out the drained solution, and wash it with water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com