A magnetic tile surface defect inspection system and inspection method

A defect inspection and magnetic tile technology, which is applied in material weighing, instruments, measuring devices, etc., can solve the problems of poor inspection effect, low efficiency of manual detection of magnetic tiles, high false detection rate, etc., to achieve convenient and accurate suction, and realize full automation And intelligent, improve the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

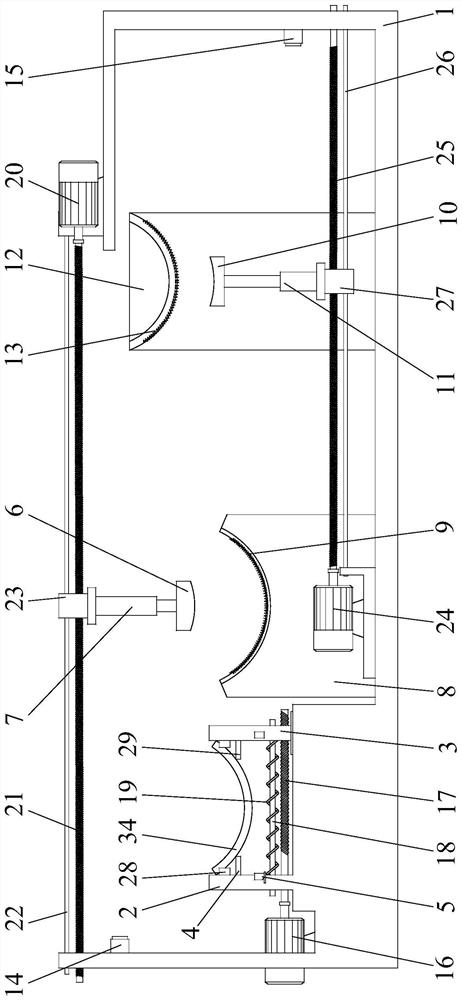

[0080] see figure 1 as well as figure 2 , this embodiment provides a magnetic tile surface defect inspection system, which is used in the defect inspection link in the magnetic tile production process. The magnetic tile surface defect inspection system can be directly installed on the existing magnetic tile production line, or it can be combined with other equipment and used as a part of other equipment, or it can be designed separately and used as a single magnetic tile inspection equipment. use. The magnetic tile surface defect inspection system can inspect magnetic tiles of various sizes, and detect defective magnetic tiles in time during the inspection process, so that these defective magnetic tiles can be recovered and reused, which can improve The yield rate in the magnetic tile production process improves the inspection efficiency and inspection effect. Wherein, the magnetic tile surface defect inspection system includes a housing 1, a clamping device, a transmissio...

Embodiment 2

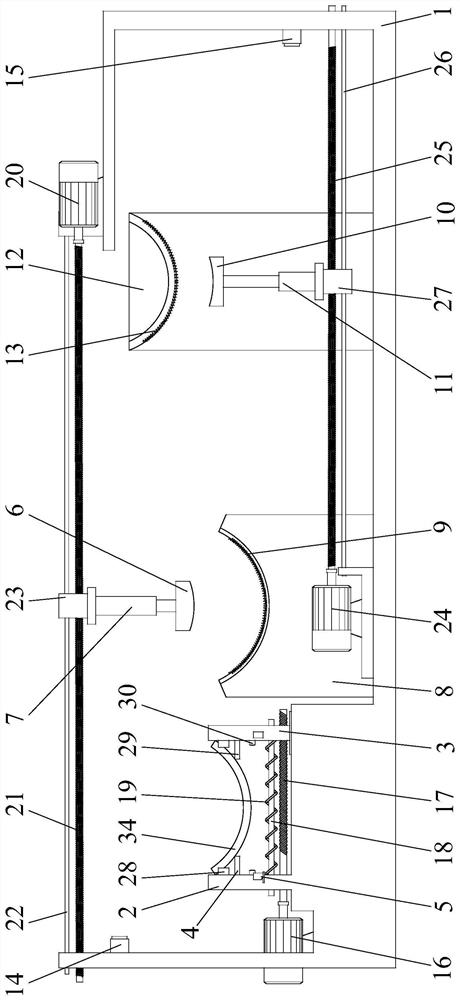

[0108] see image 3 , The present embodiment provides a magnetic tile surface defect inspection system, which adds an infrared sensor-30 and a tilt alarm that belong to the clamping device on the basis of Embodiment 1. The emitter and receiver of infrared sensor one 30 are installed on the fixed baffle 2 and the movable baffle 3 respectively, and the light emitted by the emitter passes through the space below the magnetic tile 34 on the positioning assembly 4 to be transmitted to the receiver. When the magnetic tile 34 is tilted, the convex end of the magnetic tile 34 blocks the light so that the infrared sensor 30 generates a switch signal . When the infrared sensor 130 sends a switch signal 1, the controller drives the tilt alarm to send a tilt alarm signal. In this way, when the magnetic tile 34 is inspected for defects, when it is placed crookedly, the tilt alarm will send an alarm signal. At this time, the magnetic tile 34 can be adjusted in time to ensure that the inspe...

Embodiment 3

[0110] see Figure 4 , this embodiment provides a magnetic tile surface defect inspection system, on the basis of Embodiment 1, a weighing device is added to the system. The weighing device includes a load cell one 31 and a load cell two 32 . The weighing sensor one 31 is installed between the electromagnet one 6 and the telescopic piece one 7, and is used for detecting the weight of the magnetic tile 34 adsorbed on the electromagnet one 6. The second load cell 32 is installed between the second electromagnet 10 and the second telescopic member 11, and is used to detect the weight of the magnetic tile 34 adsorbed on the second electromagnet 10.

[0111] Wherein, the controller is also used to judge whether the weight detected by the first load cell 31 or the second load cell 32 is equal to a preset weight. When the weight detected by the first load cell 31 or the second load cell 32 is greater than the preset weight, the controller determines that the magnetic tile 34 has an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com