Gas diffusion layer, preparation method thereof and fuel cell

A gas diffusion layer and slurry technology, used in fuel cells, battery electrodes, circuits, etc., can solve the problems affecting the performance and life of gas diffusion layers and fuel cells, PTFE condensation, poor coating consistency, etc., to improve performance and Long life, good flatness and uniform thickness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

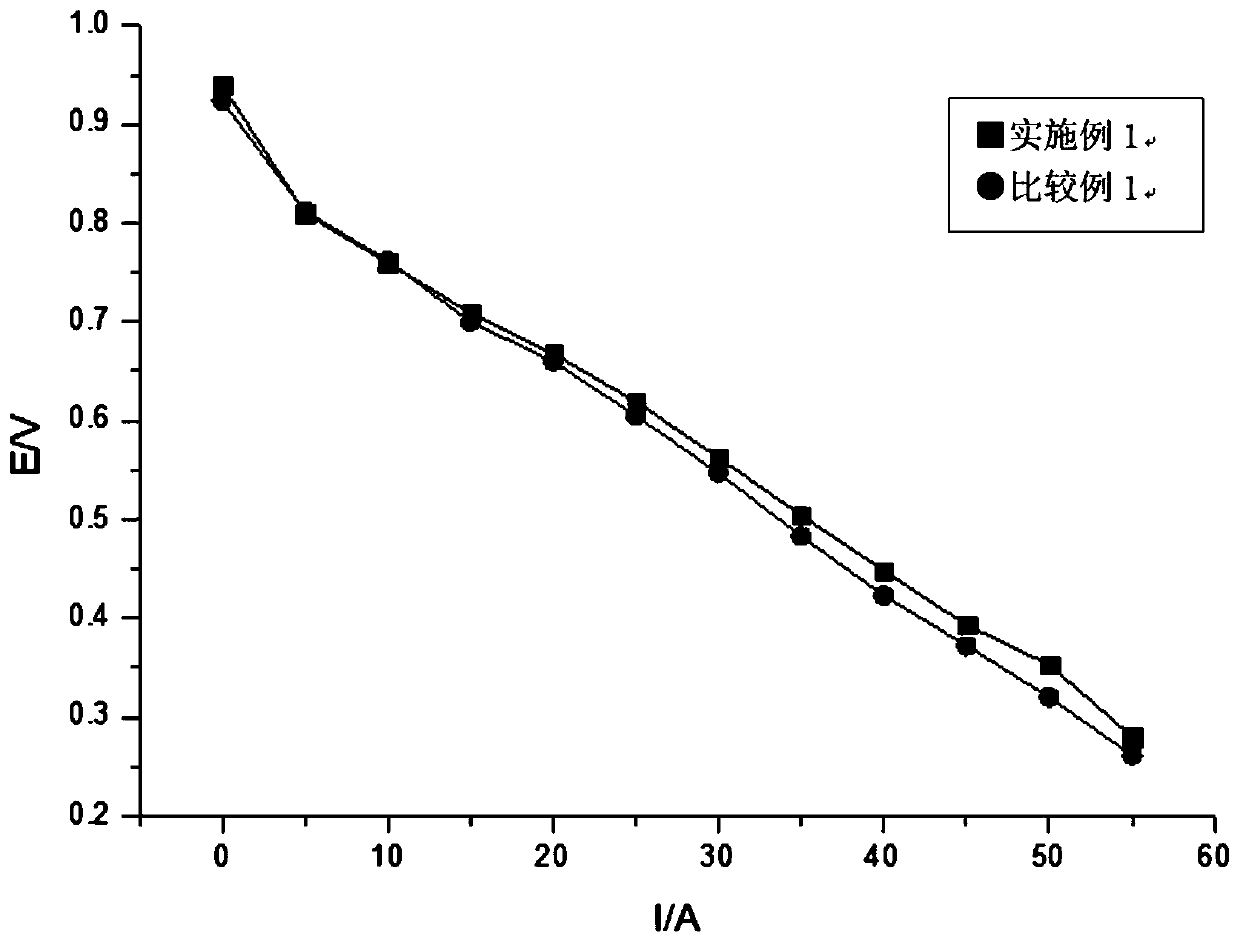

Examples

preparation example Construction

[0031] Embodiments of the present invention provide a method for preparing a gas diffusion layer, which includes the following steps:

[0032] (1) Microporous layer slurry preparation step: prepare a mixed slurry containing conductive powder and hydrophobic agent.

[0033] Specifically, the conductive powder and the hydrophobic agent are added to the low-boiling alcohol-water mixed solvent according to the mass percentage of 55-85% and 10-30% respectively, and then ultrasonic, sheared, and pulverized to form a uniformly dispersed mixed slurry.

[0034] Preferably, the conductive powder is added into the alcohol-water mixed solvent and stirred evenly, and then an appropriate amount of hydrophobic agent emulsion is added dropwise therein. Ultrasonic, shear dispersed the slurry for 30-60 minutes.

[0035] Preferably, the conductive powder is preferably conductive carbon powder. Preferably, the conductive powder is one or more of XC-72 conductive carbon powder, BP2000 conductive...

Embodiment 1

[0049] 1) Add 50g of XC-72 conductive carbon powder to 10mL of 30% propanol solution by mass fraction and stir to obtain a dispersion; then add 20g of PTFE emulsion with a mass fraction of 30% to the dispersion, Then ultrasonication and shearing were performed successively for 30 min each to obtain a mixed slurry.

[0050] 2) Use an ultrasonic sprayer to spray the mixed slurry at a temperature of 100°C on the hydrophobically treated carbon paper at a speed of 1mL / min, and change the number of spraying times according to the solid content of the mixed slurry and the spraying flow rate until the carbon paper loading capacity (that is, the load of the support layer) reaches 0.5mg / cm 2 .

[0051] 3) Put the sprayed carbon paper in a vacuum oven, and sinter at a temperature of 300°C for 40 minutes at a high temperature to obtain a gas diffusion layer.

Embodiment 2

[0053] The difference between embodiment 2 and embodiment 1 is: the PTFE emulsion in step 1) is replaced by the copolymer FEP emulsion of tetrafluoroethylene and hexafluoropropylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com