Efficient cooling crystallization kettle

A cooling crystallization and high-efficiency technology, applied in heat exchange cooling crystallization, crystallization separation, solution crystallization, etc., can solve the problems of normal crystallization production safety hazards in crystallization kettles, affect product production quality, increase the pressure of crystallization kettles, etc., and achieve simple structure , ingenious design, the effect of eliminating fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

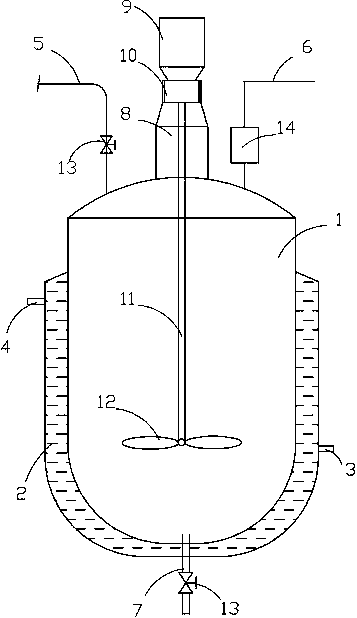

[0009] see figure 1 , a high-efficiency cooling crystallization kettle, which has a kettle body 1, and the outer wall of the kettle body 1 is equipped with a jacket 2 for containing -10°C ice salt water, and an ice salt water inlet 3 and an ice salt water outlet 4 are respectively provided on the jacket 2; The top of the kettle body 1 is provided with a feed inlet 5 and an exhaust gas outlet 6, and the bottom of the kettle body 1 is provided with a discharge outlet 7; a fixed seat 8 is provided on the top of the kettle body 1, and a stirring motor 9 and a matching motor are installed on the fixed seat 8. Gear box 10, the output end of the gear box 10 is connected to the rotating shaft 11 extending into the kettle body 1, and the bottom end of the rotating shaft 11 is equipped with a stirring impeller 12; the pipeline where the inlet 5 and the outlet 7 are located All are equipped with a control valve 13; the pipeline where the waste gas outlet 6 is located is equipped with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com