Preparation method of carbon fiber cloth heating sheet

A technology of carbon fiber cloth and heating sheet, which is applied in the fields of medical treatment, textile and sports equipment, and can solve problems such as unsafety, uneven heating, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

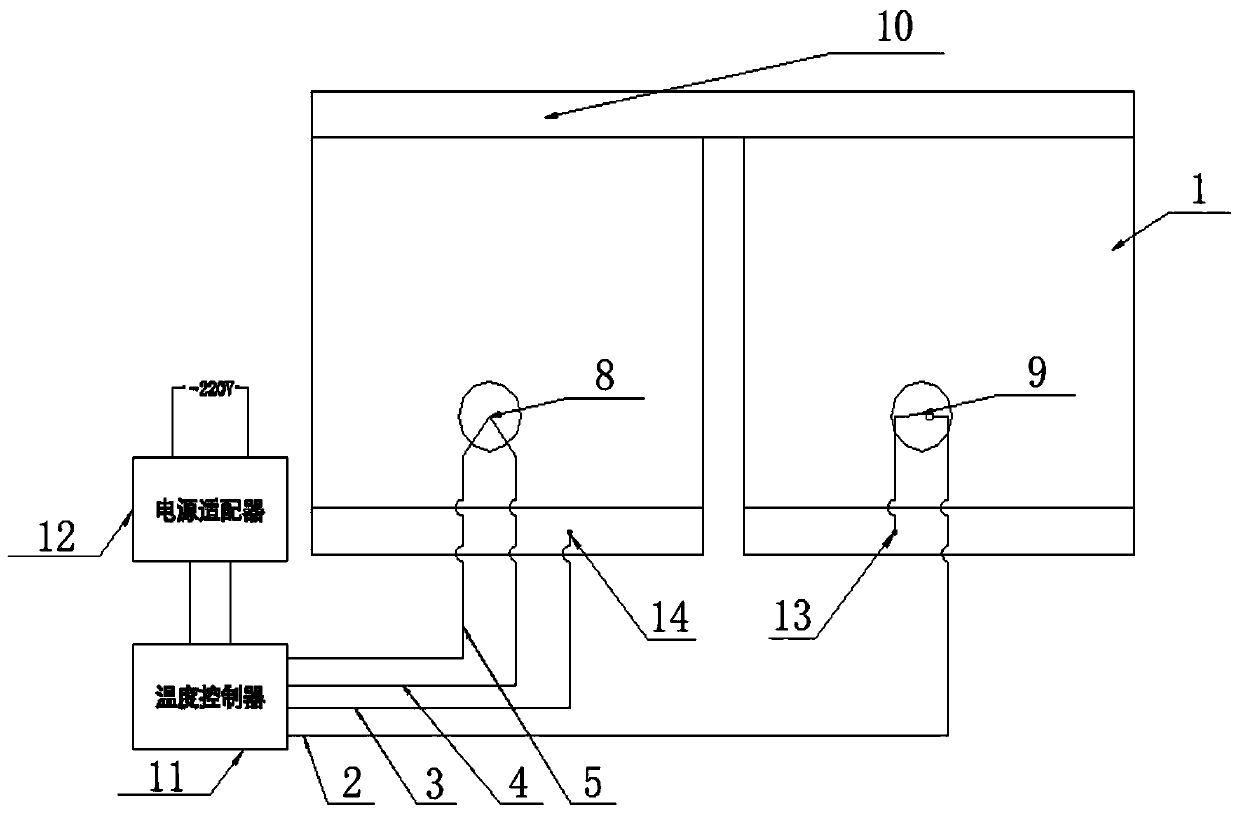

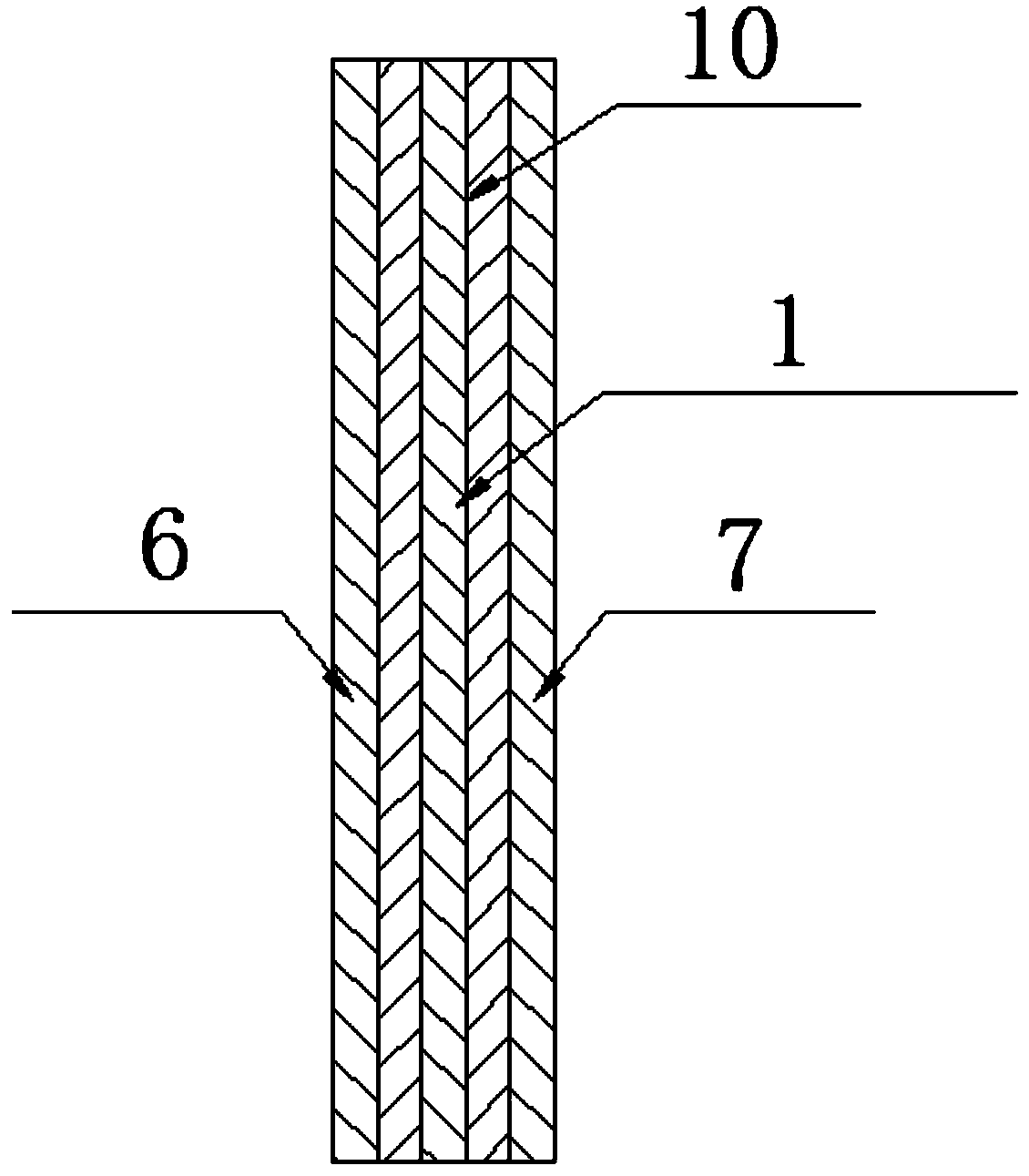

[0034] S1. First select a plurality of carbon fiber bundles, and then cross-weave the plurality of carbon fiber bundles into a strip-shaped conductive carbon fiber cloth 1. The formation of multiple fiber bundles is formed by discontinuous fibers that have undergone graphitization high-temperature treatment. The strip-shaped conductive carbon fiber cloth 1 is Graphitized carbon fiber cloth;

[0035] S2. First, the first protective layer 6 and the strip-shaped conductive carbon fiber cloth 1 are bonded together with thermoplastic polyurethane elastomer rubber, and they need to be smooth, and then use a brushing tool to evenly coat the conductive silver paste or missile carbon paste with the strip shape. The position of 13 centimeters of conductive carbon fiber cloth 1 both ends, the first protective layer 6 is flannelette, and bonding agent is the conductive silver paste that contains 80% weight;

[0036]S3. Then place the coated heating sheet in an oven, and dry it for 27 minu...

Embodiment 2

[0041] S1. First select a plurality of carbon fiber bundles, and then cross-weave the plurality of carbon fiber bundles into a strip-shaped conductive carbon fiber cloth 1. The formation of multiple fiber bundles is formed by discontinuous fibers that have undergone graphitization high-temperature treatment. The strip-shaped conductive carbon fiber cloth 1 is Polyacrylonitrile carbon fiber cloth;

[0042] S2. First, the first protective layer 6 and the strip-shaped conductive carbon fiber cloth 1 are bonded together with thermoplastic polyurethane elastomer rubber, and they need to be smooth, and then use a brushing tool to evenly coat the conductive silver paste or missile carbon paste with the strip shape. Conductive carbon fiber cloth 1 both ends 10 centimeters position, first protection layer 6 is flannelette, and bonding agent is carbon content in 88% conductive carbon paste;

[0043] S3. Then place the coated heating sheet in an oven, and dry it for 25 minutes at a tempe...

Embodiment 3

[0048] S1. First select a plurality of carbon fiber bundles, and then cross-weave the plurality of carbon fiber bundles into a strip-shaped conductive carbon fiber cloth 1. The formation of multiple fiber bundles is formed by discontinuous fibers that have undergone graphitization high-temperature treatment. The strip-shaped conductive carbon fiber cloth 1 is Graphitized carbon fiber cloth;

[0049] S2. First, the first protective layer 6 and the strip-shaped conductive carbon fiber cloth 1 are bonded together with thermoplastic polyurethane elastomer rubber, and they need to be smooth, and then use a brushing tool to evenly coat the conductive silver paste or missile carbon paste with the strip shape. The position of 15 centimeters of conductive carbon fiber cloth 1 both ends, the first protective layer 6 is flannelette, and binding agent is the conductive silver paste that contains 60% weight;

[0050] S3. Then place the coated heating sheet in an oven, and dry it for 30 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com