Technological process and equipment for treating municipal sludge with earthworms

A technology of municipal sludge and process flow, applied in biological sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of inability to eliminate pollutants such as heavy metals, large floor space, and long composting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

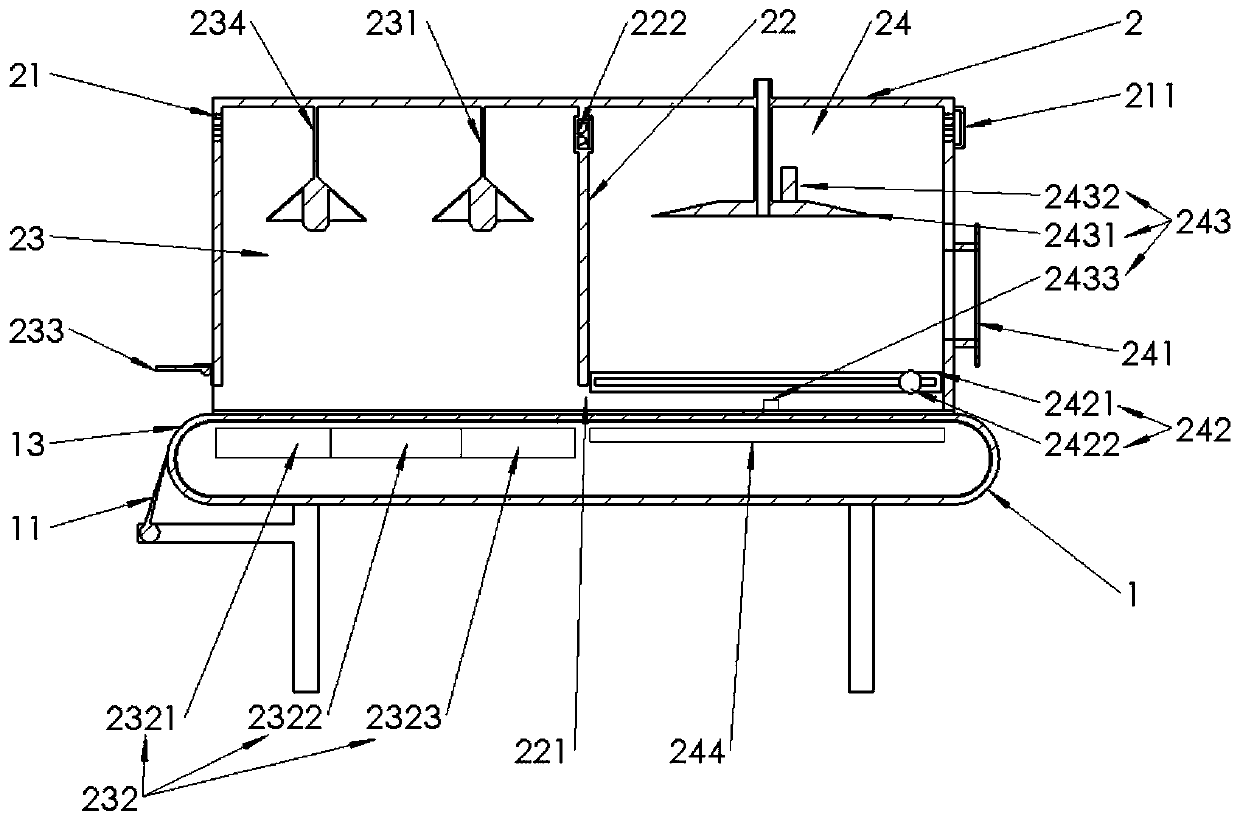

[0089] refer to figure 1 with figure 2 , the invention provides a kind of technological process of earthworm treatment municipal sludge, comprising the following steps:

[0090]B. flattening inoculation: the sludge is sent to the conveyor belt 1 in the treatment chamber 24 to be flattened, and the flattened thickness is 5-10 cm, and the earthworm is inoculated, and the inoculation amount is 20-40 kg / square meter;

[0091] C. Earthworm treatment: keep the treatment room at 24°C at a temperature of 15-25°C, shading and ventilating, and treat earthworms for 2-7 days;

[0092] D. transfer sludge: Utilize conveyor belt 1 to transfer the sludge after the earthworm treatment from the treatment chamber 24 to the adjacent drying chamber 23;

[0093] E. Heating and repelling: use the heating device at the bottom of the drying chamber 23 to heat the sludge, the temperature is not higher than 40°C, heat for 1-2 days, and use strong light to drive away the earthworms, and drive them to ...

Embodiment 2

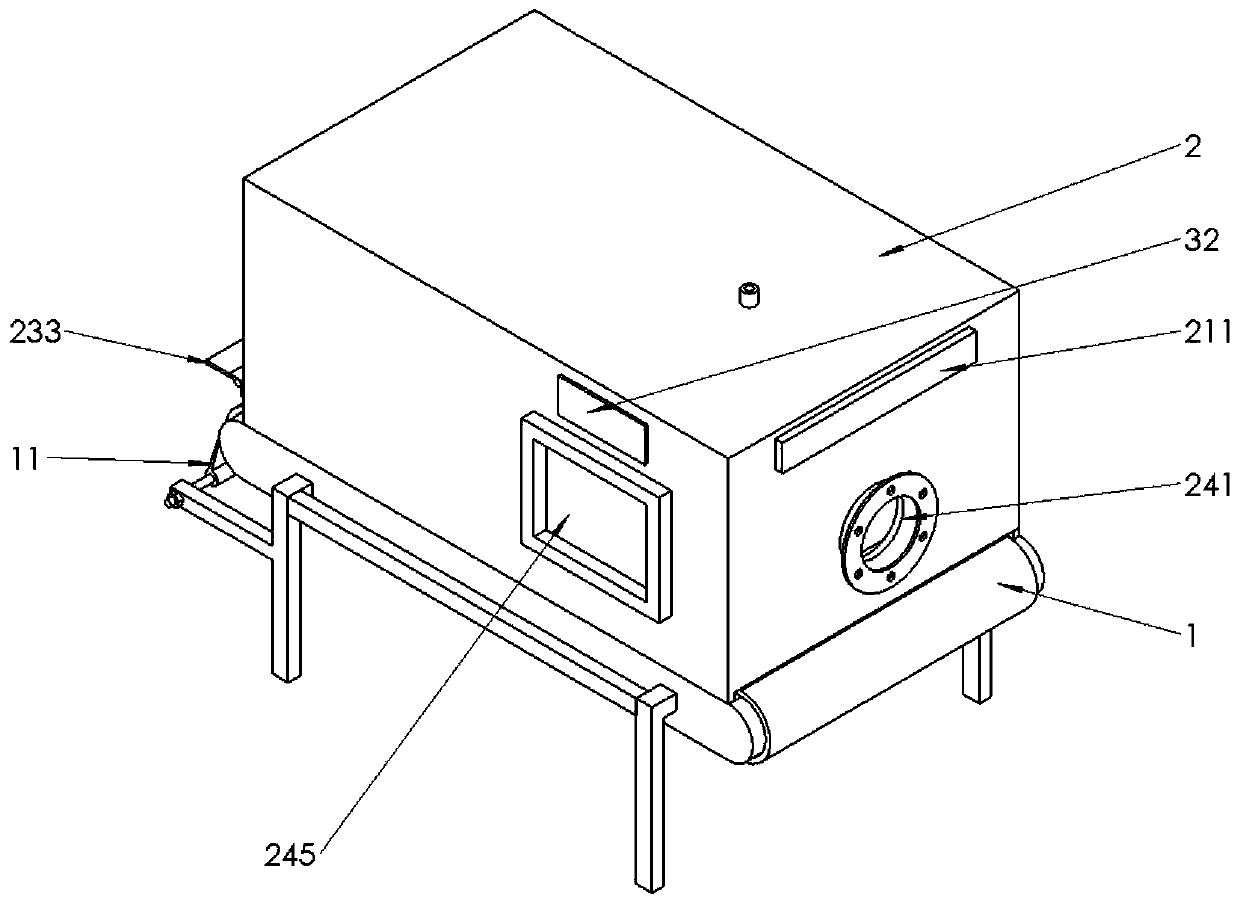

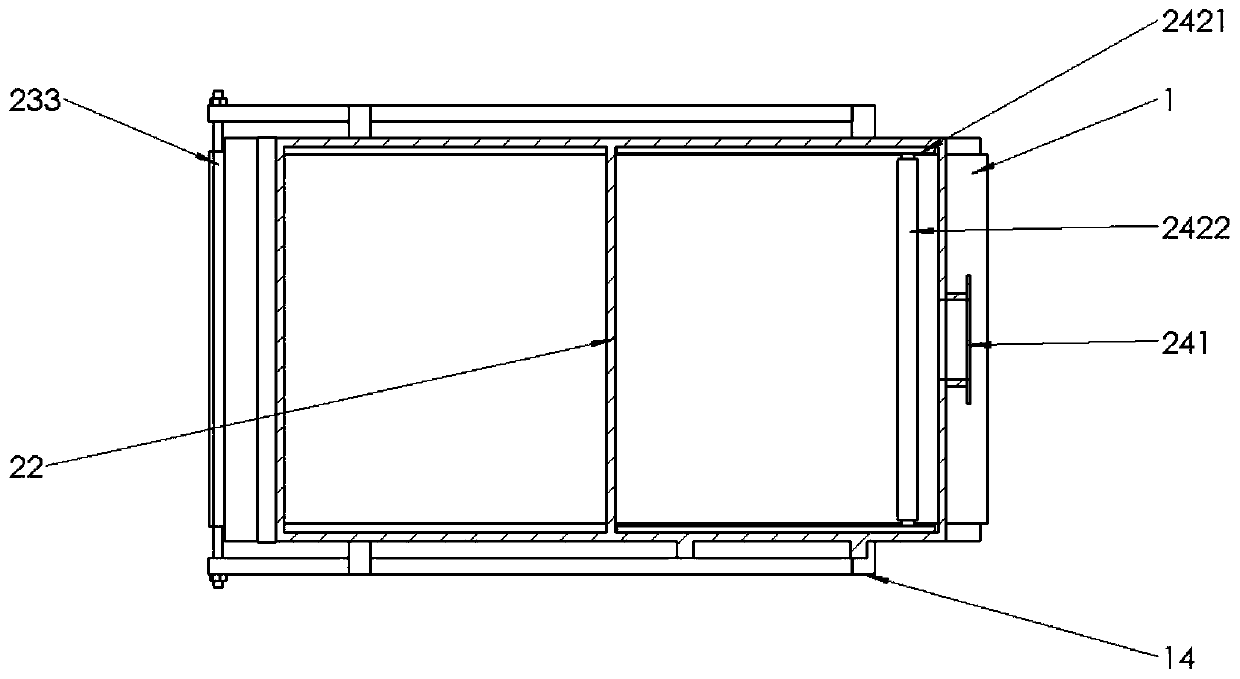

[0113] refer to Figure 1-Figure 3 , another aspect of the present invention provides a kind of earthworm processing municipal sludge equipment, including a conveyor belt 1 and a casing 2 arranged thereon; the casing 2 is provided with a ventilation hole 21, and the ventilation hole 21 is provided with a filter 211, the shell 2 is provided with a partition 22 to form a drying chamber 23 and a processing chamber 24, the bottom of the partition 22 is provided with a through hole 221; the processing chamber 24 is provided with a feed port 241, a flattening device 242. The temperature and humidity control device 243, the drying chamber 23 is provided with a fluorescent lamp 231, and the bottom of the drying chamber 23 is provided with a drying heating device 232; the turning point of the conveyor belt 1 close to the drying chamber 23 is provided with scraper11.

[0114] Adopt above-mentioned scheme, the earthworm processing process is closed by described casing 2, provide the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com