Carbon silica gel high-pressure steel wire braided rubber pipe for oil well

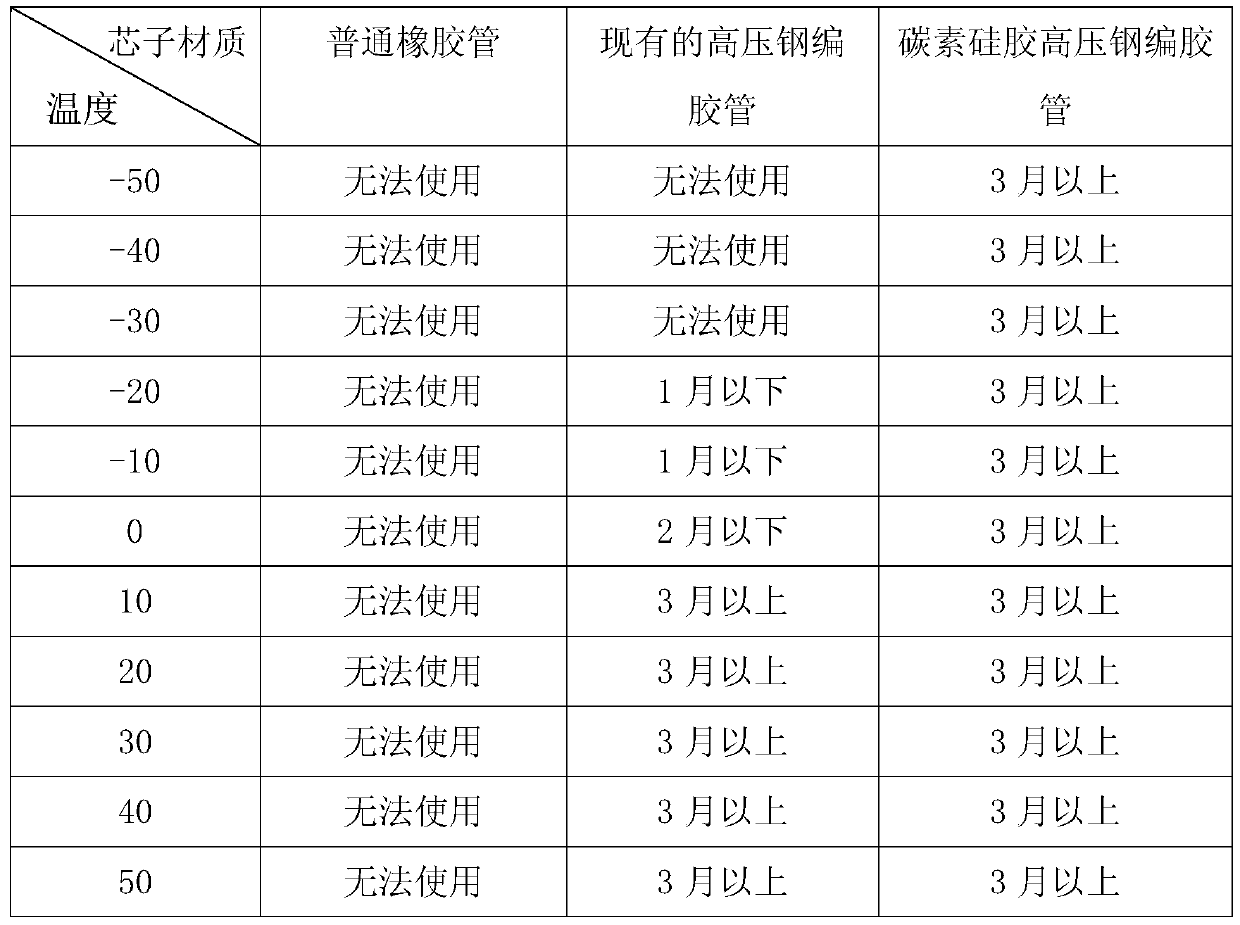

A steel wire braided rubber hose and silica gel technology, which is applied in the petroleum field, can solve problems such as high cost, short service life of the hose, and impact on personal safety, and achieve the effects of improving compactness and strength, increasing service life, and reducing pipeline quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

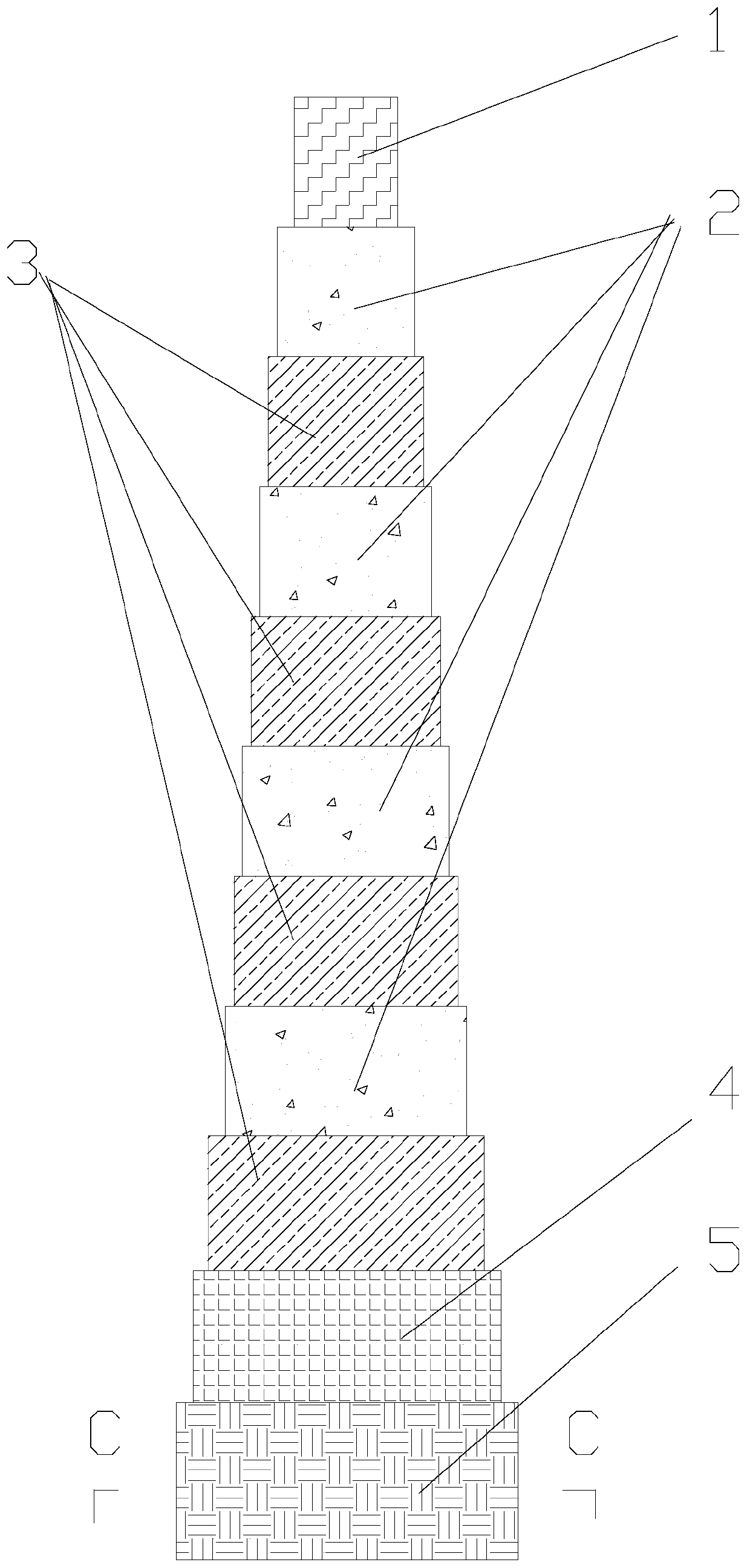

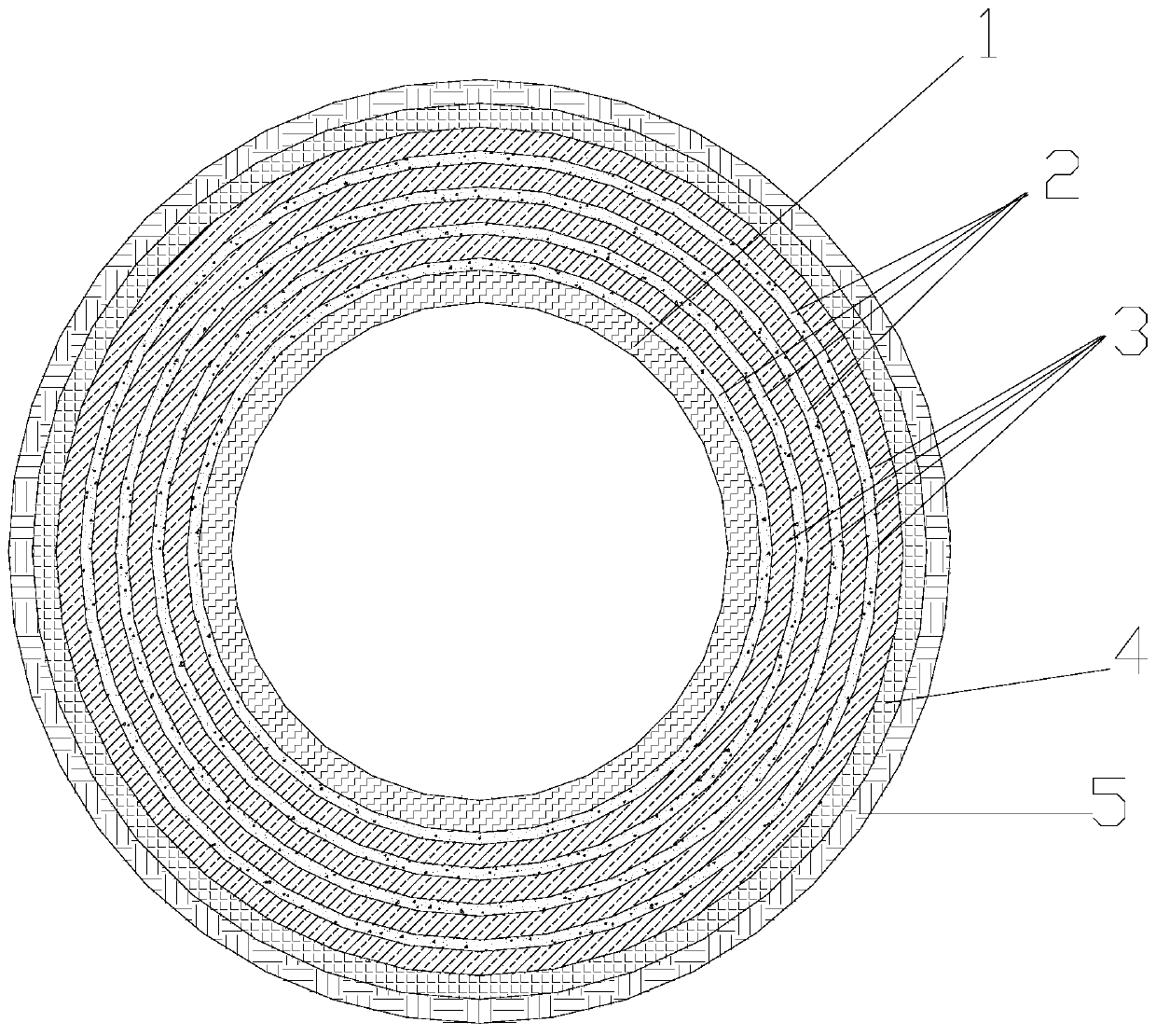

[0031] Examples, see attached Figure 1-2 , a carbon silica gel high-pressure steel wire braided rubber hose for oil wells, which includes an inner rubber hose 1, and the inner rubber hose is mainly composed of 10-16% carbon, 42-53% silica gel, 12-18% graphite nanometer and Composed of 22-27% nitrile rubber components; a steel wire braided layer 3 is arranged on the outside of the inner rubber tube, a canvas layer 2 is arranged between the steel wire braided layer and the inner rubber tube, and pulp is brushed on both sides of the canvas layer glue, the paste glue contains a bonding promoter, and the bonding promoter consists of 20-24 parts of cobalt stearate, 45-60 parts of p-benzoate, 4-10 parts of silane coupling agent, 1-5 parts of fatty acid and 15-22 parts of gypsum, the canvas layer and the steel wire are braided to repeat more than three layers at intervals, the diameter of the steel wire is 1-2mm, and the surface of the steel wire is coated with a galvanized layer. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com