Method for determining content of silicate minerals and slag in Portland slag cement

A technology for Portland cement and silicate minerals, applied in the field of detection and analysis, can solve the problems of inability to calculate the relative content of unknown phases, powerlessness, and complicated pre-treatment, and achieve rapid and effective inspection and control methods to ensure stability , the effect of scientific methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to better understand the essence of the present invention, the technical solution of the present invention will be further elaborated below through specific examples.

[0057] Embodiments of the present invention include the following steps:

[0058] (1) Establishment of some or all unknown crystal structure phases of slag:

[0059] In order to establish the typical partially known or completely unknown crystal structure phases of slag, it is necessary to collect common slags from cement plants for statistical analysis.

[0060] For this reason, the slag samples used by 10 cement plants were collected (one sample per plant), and the details are shown in Table 2:

[0061] Table 2 Slag statistics

[0062]

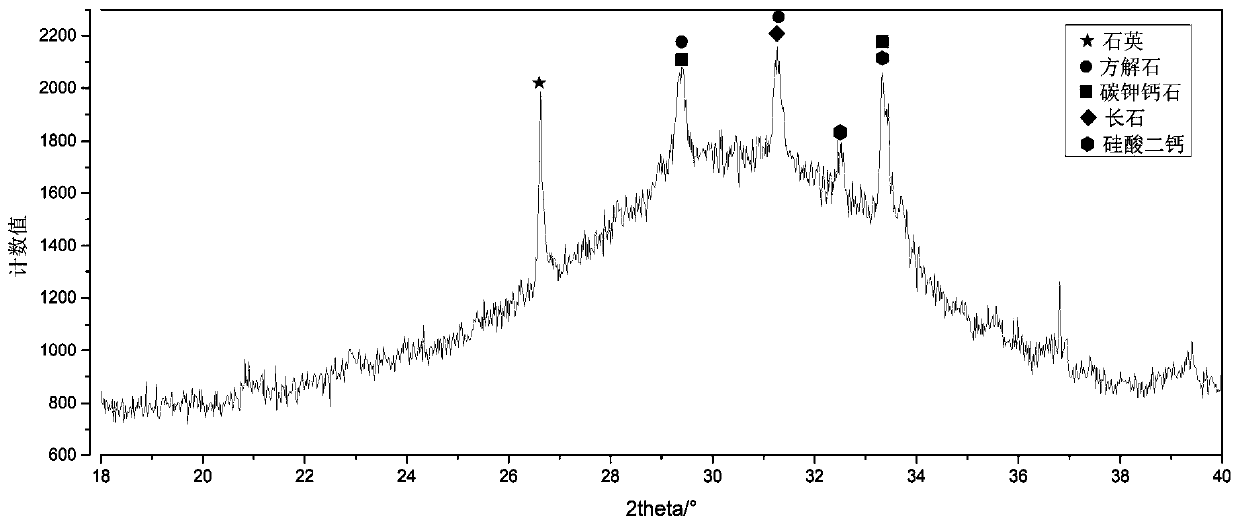

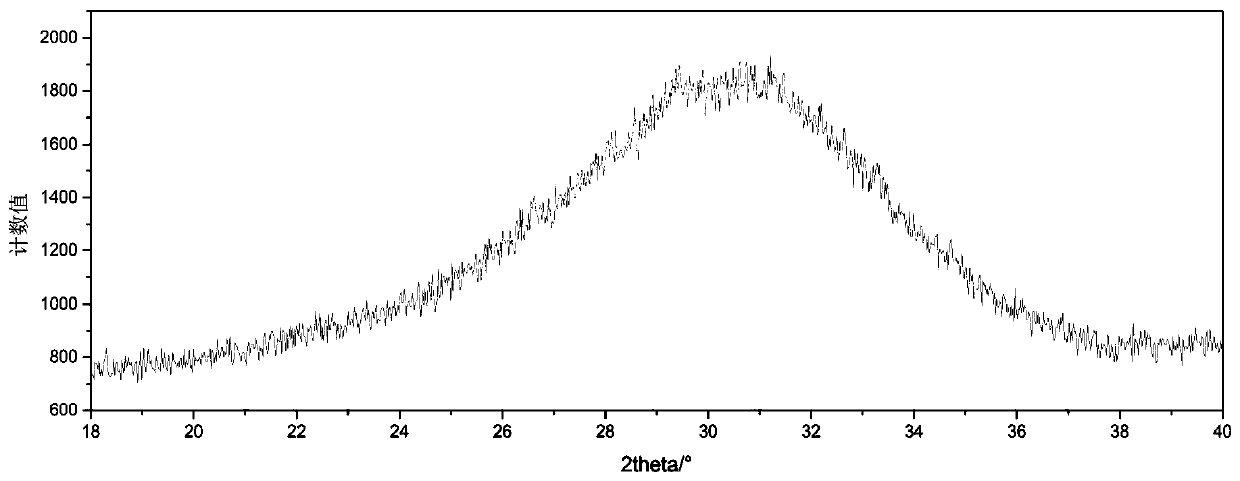

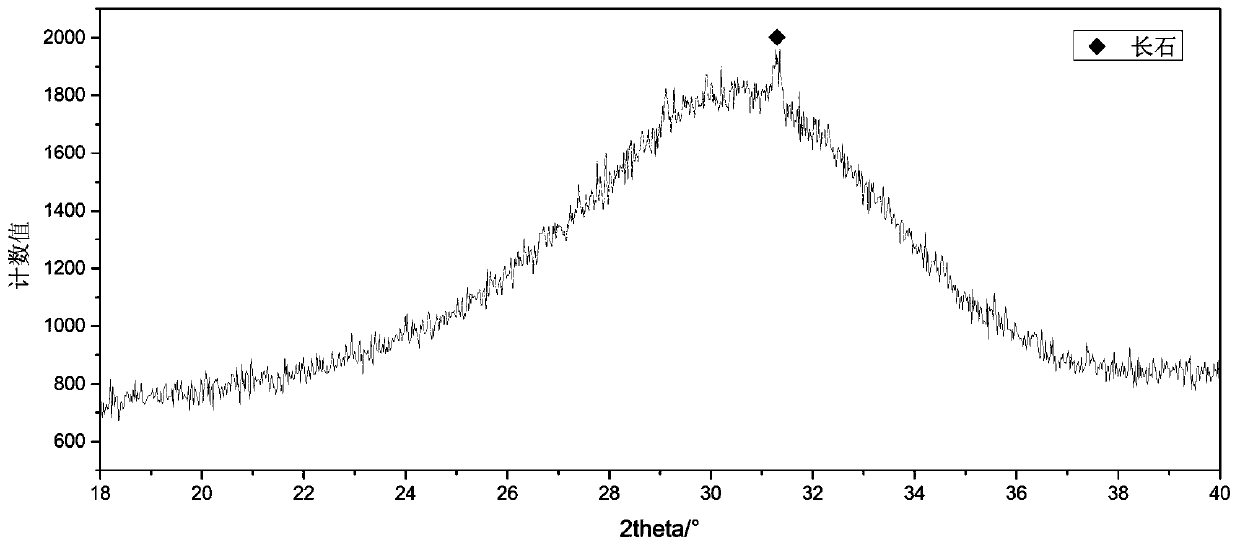

[0063] Dry and grind the above-mentioned slag so that its average particle size is controlled at about 7 μm. Acquisition of slag X-ray diffraction data was carried out according to the following experimental parameters and conditions: voltage and current...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com