Electromagnetic Ultrasonic Probe, Flaw Detection Device and Flaw Detection Method for Continuous Inspection of High Temperature Casting and Forgings

A technology of continuous detection and electromagnetic ultrasound, which is applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis. , high lift-off sensitivity and other issues, to achieve good heat insulation effect, increase distance, and reduce lift-off distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

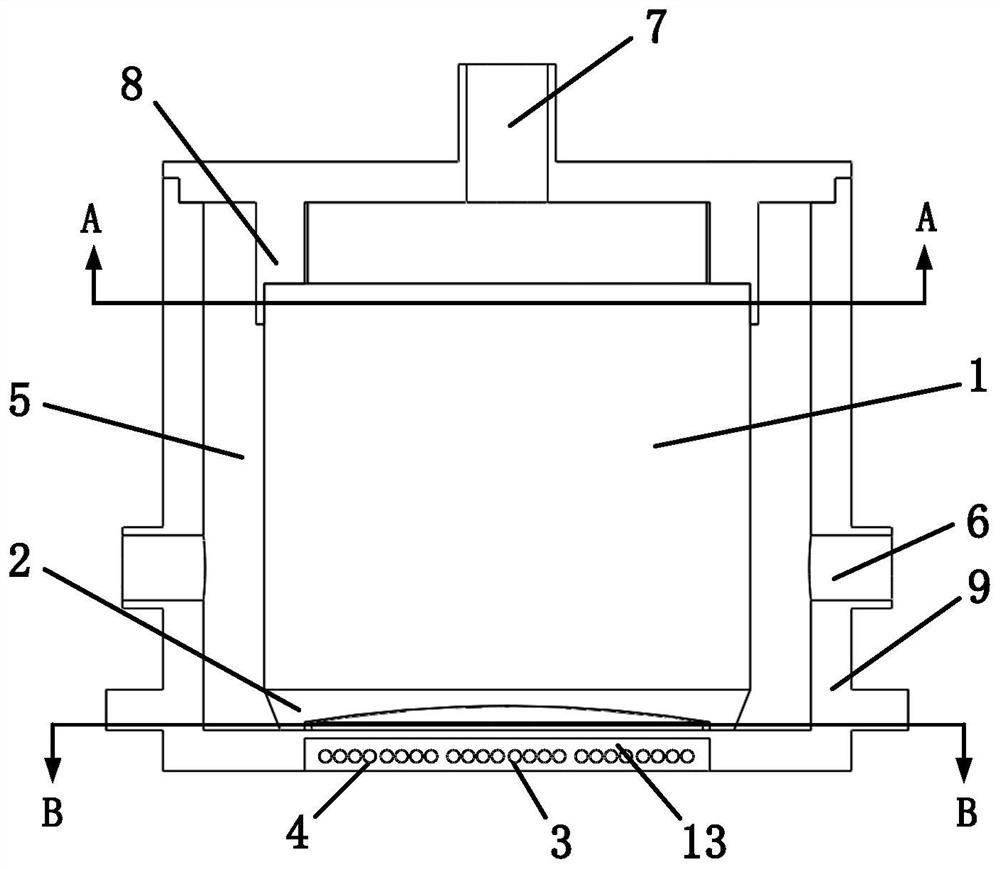

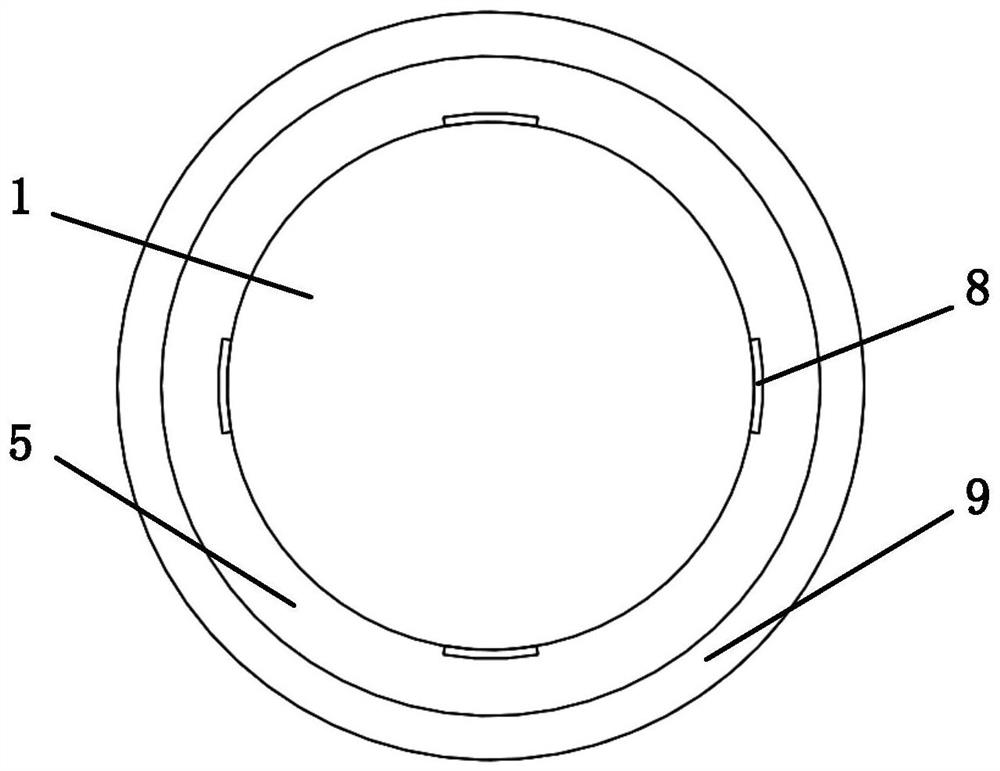

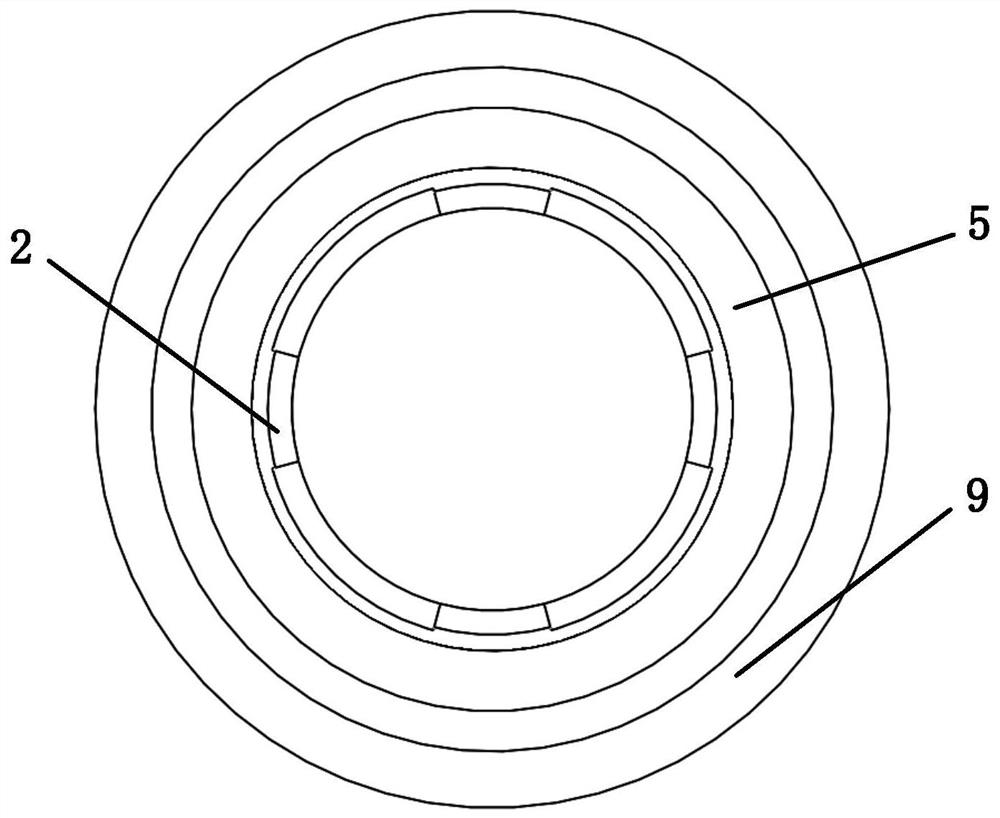

[0053] The specific embodiment of the present invention provides a casting and forging electromagnetic ultrasonic probe, such as Figure 1 to Figure 6 As shown, including the probe housing 9, the permanent magnet 1 arranged in the cavity of the probe housing 9, the excitation coil 3 and the receiving coil 4 arranged under the outer bottom of the probe housing 9, the excitation coil 3 and the receiving coil 4 are both wires The spiral coil structure wound parallel to the bottom of the probe housing 9, the wire is made up of 3 to 35 silver wires 11 uniformly coated with the ceramic coating 10 bundled into a cluster; the permanent magnet 1 is provided with a high temperature resistant Magnetic base 2, the central axis of the magnetic base 2 is perpendicular to the plane where the excitation coil 3 is located; the side wall of the probe housing 9 is provided with a number of water suction ports 6 near the bottom. The top of the probe housing 9 is provided with a water outlet 7 , a...

Embodiment 2

[0067] like Figure 8 As shown, the specific embodiment of the present invention provides an electromagnetic ultrasonic flaw detection device for continuous detection of high-temperature castings and forgings, including the above-mentioned probe, as well as a PC, an excitation circuit and a receiving circuit;

[0068] The excitation circuit includes a DA signal generator, a power amplifier, and an excitation end impedance matching circuit connected in sequence, and both ends of the excitation coil 3 of the probe are connected to the excitation end impedance matching circuit;

[0069] The receiving circuit includes a receiving end impedance matching circuit, a preamplifier, a filter and an AD signal acquisition card connected in sequence, and both ends of the receiving coil 4 of the probe are connected to the receiving end impedance matching circuit;

[0070] The DA signal generator and the AD signal acquisition card are all connected with the PC.

[0071] The DA signal genera...

Embodiment 3

[0073] The specific embodiment of the present invention provides a flaw detection method for continuously detecting an electromagnetic ultrasonic flaw detection device by using the above-mentioned high temperature casting and forging, comprising the following steps:

[0074] A high-frequency, high-power sinusoidal pulse train current is passed into the excitation coil 3, and the high-frequency, high-power sinusoidal pulse train current signal generates a pulsed eddy current in the test sample, and generates a Lorentz force under the action of the bias magnetic field. Or the sinusoidal pulse current signal generates a high-frequency alternating magnetic field signal in the test sample, which makes the surface of the test sample generate Lorentz force or magnetostrictive deformation, causing the surface of the test sample to vibrate, thereby exciting the transverse wave ultrasonic wave. The upper surface of the sample to be tested propagates from top to bottom, that is, along the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com